1.Form area: 1000*1100mm

2.Form depth: 80mm

3.Functions: form,cut, stack

Factory Direct Sales PS foaming sheet machine

The PS food container machine mainly including three main parts:

1. PS foam sheet extruder: make PS foam sheet from raw material

2. Fully auto forming and cutting machine: make PS sheet to finished products, such as PS foam tray, PS foam box etc (we can design mould according to customer requirements)

3. Plastic recycle machine: recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again

We specialize in making plastic machines for 30 years with advanced technology and have accumulated vast experience. Our machines are sold well in many countries such as England, Brazil, Portugal, India, Russia, Uzbekistan, Iran, Indonesia, Cambodia and so on. Sincerely hope to have chance to cooperate with you in near future.

Factory Direct Sales PS foaming sheet machine

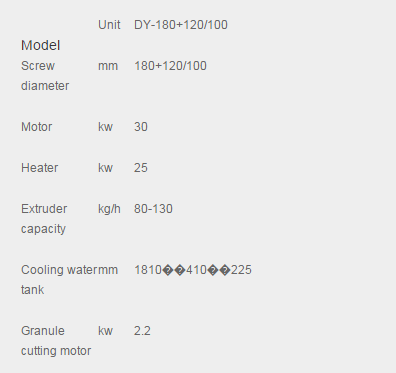

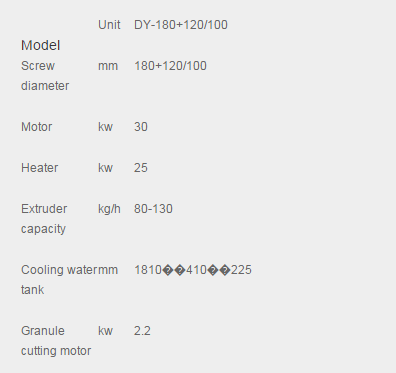

PS Foam Sheet Extruder

PS Foam Sheet Extruder uses a tandem screw technology to produce fine-block cell-structured extruded polystyrene foam sheet with high strength and a pearl and even surface, in a continuous roll, from polystyrene injection an eco-friendly blowing gas and additives. It has a user friendly operating system with inverter controlled driving, digital temperature control and so on.

Main technical parameters

Factory Direct Sales PS foaming sheet machine

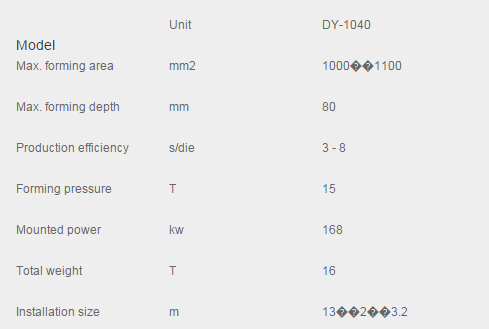

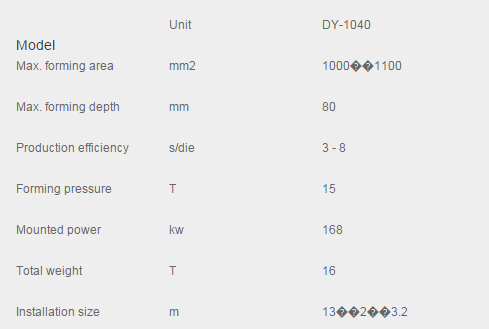

B. Fully auto forming and cutting machine

Fully automatic forming and cutting machine integrates forming, cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program. Two workers are enough for whole production line.

The machine is plastic sheet forming equipment in one step with following process: transporting sheet, heating, forming, cutting, stacking and winding waste edge.

Factory Direct Sales PS foaming sheet machine

C.Plastic recycle machine

Plastic recycle and pelletizing machine is designed to reclaim the foamed polystyrene materials almost identically to new ones with its own superior filtering performance.

Structure

-- Extrusion unit

-- T-die with screen changer

-- Cooling water bath unit

-- Pelletizing unit

-- Control panel unit

Main technical parameters