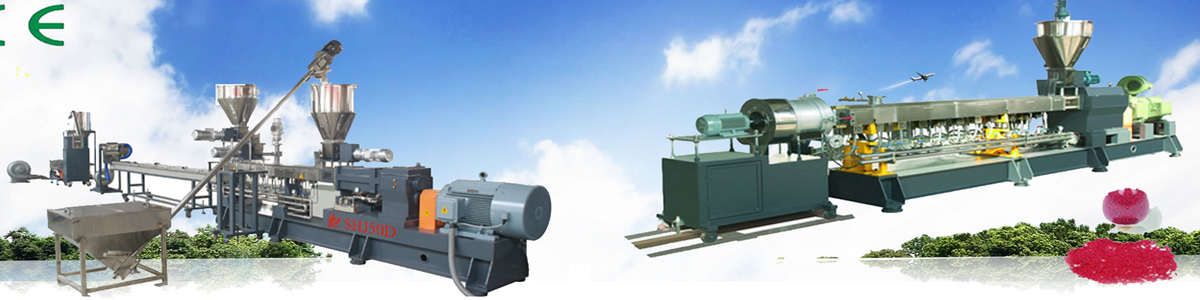

SJ-100 Single Screw Extruder

High precision gear box, high carrying capacity, steady driving, low noises.

Newly designed barrel and screw ensure better melt uniformity; low melt temperature and much higher production

For most applications, standard intruded steel is used for barrels and screws with high corrosion-resistant

The unusual material can be processed by choosing bimetallic material

Supper mute blower fan cools barrel with no maintenance

The die head have two types: manual whirling and hydraulic pressure screen changer. Chaing screen is easy and finished within a few minutes.

Characteristics and application of single screw stem recoveryeries. These series can process various kinds of recovered materials, including PE, PP, PS, PA, PET,PC, etc. In many status: such as slices, film, and small pieces. And based on the chemical and physical characteristics of materials as weel as the output requirements of the customers, we have designed various kinds of granulation auxiliary machines ( air-cooling strands pelletizing and water-ring die face cutting, etc) for the single screw stem extrusion machine with complete specifications and technical parameters.

Model | D(mm) | L/D | P(KW) | Screen chagner | Output (kg/h) |

SJ-100 | 100 | 24-38 | 45-90 | hydraulic | 100-250 |

SJ-120 | 120 | 24-38 | 75-132 | hydraulic | 200-450 |

SJ-150 | 150 | 24-38 | 110-185 | hydraulic | 300-700 |

SJ-180 | 180 | 24-38 | 160-250 | hydraulic | 400-900 |

SJ-200 | 200 | 24-38 | 200-355 | hydraulic | 800-1500

|