We only use quality 304 stainless steel or 316L stainless steel

Welders who have been welding for more than ten years only.

Key components only use internationally renowned brands

Such as: SIEMENS, ABB, Alfa Laval control instrument using the best

No matter which part of the weld is welded, we shall protect it with argon of 9999.9% purity.

Product Description

Juice production line

Specifications

1. Juice production line, apple,orange,mongo,pineapple,guava,bissap,grape,banana,olive,coconut,lychee,kiwi,banana, tropical fruits processing

2. All production capacity

3. Factory and hotel are suitable

Main Description

1. Fruit juice plant

2. CE GAP ISO approved

3. From water treatment to package

4. PLC control

5. High efficiency

6. 60- 1500 tons / day

Main technical parameter

1 The processing capacity is varied from 60 tons/day to 1500 tons/day.

2 The line Can deal with similar characteristic of fruits.

3 Using the high efficient of destoner to improve the mango output percentage effectively

4 Using efficient belt juice extractor to improve the juice efficiency and the output percentage.

5 The production process fully automatic PLC control to save labor and Facilitate production management

6 Low-temperature vacuum evaporation ,Maximize reserve the flavor substances and nutrients also save energy.

7 Tubular UHT sterilizer and Aseptic filling machine, produce high-quality aseptic juice products

8 Automatic CIP cleaning ,ensure the entire line equipment of food hygiene and safety requirements

E. Other models

| Raw material: | Peach,apricot,plum and other similar flesh fruits with hard seed |

| End product: | Nature Juice, juice Concentrate, transparent juice, cloudy juice, canned fruits |

| Production capacity: | 20T/D-2000T/D |

| Output percentage: | ≥90% |

| Solid content | 7~12Brix |

| Packing type for end product: | Aseptic Bag/glass Bottle/PET Bottle /gable Top Box/Tetra Pak |

| Raw material | Fresh Mango / pineapple |

| End product | Transparent juice and cloudy juice, concentrated juice and nfc |

| Processing capacity | 60- 1500 tons / day |

| Output percentage | 50-75% |

| Solid content in NFC | 10-20Brix |

| Solid content in concentrated juice | 60~72Brix |

| End package | Aseptic bag/gable top box/tetra pak/PET bottle |

Main technical parameter

1. Those lines are applicable for all kinds of hard seed fruits with pulp, such as peach, apricot, plum etc.

2. Flexible configuration to make this line, according to different requirements of the end products, some exact equipments with different functions are flexible chosen, for example: enzymolysis, evaporation etc.

3. According to different investment and product structure prefered, client can require average, middle level or high level processing equipments.

4. End product with pure flavor, bright colour, and high juice output percentage;

5. Whole line with features as high level automatically, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can clean thoroughly, with high level sanitation.

Accessory equipment

Product application

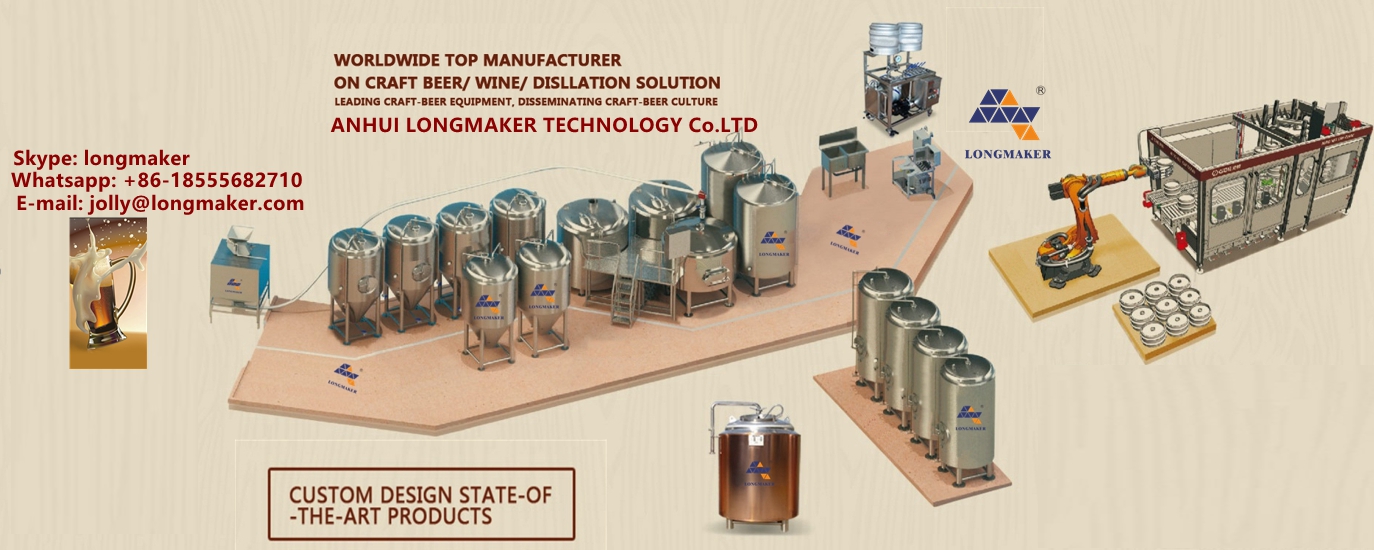

Company introduction

LONGAMKER is a professional filling,packaging,water treatment solution manufacturer from China with ISO9001:2000 & CE certification who dedicated to manufacture kinds of filling & packaging equipment & water treatment system for beverage & food field.

Built in 2006,LONGAMKER have 4000 square meters modern standard workshop & 40 professional workers,integrate the R&D department,manufacturing department,technical services department and marketing department together,provide the reliable filling system & water treatment system worldwide.

LONGAMKER Manufacture & Provide below filling & treatment system

l PET Bottle,Glass Bottle, Cans,Cups Filling & Packaging Line(Still water,Carbonated soft drink,Juice,Alcohol,Oil etc)

l 1-2 & 3-5 Gallon Jar Bottle Water Plant

l Bottle,Kind of Container Labeling Solutions

l Water Treatment System(RO Pure Water Purifier,UF Mineral Water Purifier,Brackish & Seawater Desalination Plant,Water Softener)

| Main Technical parameters |

| Model | GFR

16126 | CGFR

18186 | CGFR

24248 | CGFR

32328 | CGFR

404010 | CGFR

484812 | CGFR

606015 | CGFR

808020 |

| Heads of washing, filling, sealing | 16-12-6 | 18-18-6 | 24-24-8 | 32-32-8 | 40-40-10 | 48-48-12 | 60-60-15 | 80-80-20 |

| Production capacity(bottle/hour) | 3000-4000 | 5000-7000 | 8000-12000 | 12000-15000 | 16000-18000 | 20000-24000 | 24000-28000 | 36000-40000 |

| Suitable bottle height | H=170-320 | Φ=50-100

(330-1500ml) |

|

|

|

|

|

|

| Spraying pressure | 0.25-0.3 |

| Total Power | 1.5+0.37 | 2.2+0.37 | 3+0.45+

0.25 | 5.5 | 7.5 | 11 | 15 | 19 |

| Overall dimension(L×W×H) | 2300×

1680×

2650 | 2500×

1760×

2650 | 3100×

2100×

2650 | 3800×

2800×

2650 | 4000×

3300×

3400 | 4850×

3650×

3300 | 6500×

5400×

3500 | 7650×

6400×

2700 |

| Weight | 2600 | 3500 | 4650 | 6800 | 8500 | 1000 | 12500 | 16000 |

Main Product

1. 2000-40000 BPH Mineral Water Bottling Line;

2. 2000-40000 BPH Juice Bottling Line;

3. 2000-40000 BPH Carbonated Beverage Bottling Line;

4. 3000-40000 BPH Beer Bottling Line;

5. 6000-30000BPH Aluminium Can Filling Line;

6. 120-2000 Barrels/Hour 3-Gallon & 5-Gallon Filling Line;

7. Edible Oil Filling Line;

8. PET Preform Injection Machine;

9. Bottle Blow Moulding Machine;

10. Water Treatment;

11. UHT Plant;

12. Carbonating Mixer;

13. Bottle Unscrambler;

14. Film Shrink-wrapping or Carton Box Packaging Machine;

15. Pa-Depalletizer;

16. Turn Key Project.

Quality Control

Company has passed ISO9000: 2000 version quality system certification and all manufacture processes are conducted by the standard strictly.

All products adopt all-around computer aided design (CAD).

From processing to each process of assembly, all spare parts equip with special turn-over box to ensure not falling onto the ground during turning over.

Filling valves, capping heads and other main parts are process by digital lathe and processing center. And then they are assembled in special assembly room in order to keep their accuracy and cleanness.

All auxiliary parts adopt international and domestic famous brand products.

Before delivery time, all complete sets will test run for 3 days continuously. After quality inspection, they can be transferred to the customers.

FAQ

1.How long can I receive your reply after I send my inquiry?

We will reply you within 12 hours on workday.

2.Are you a manufacturer or a commercial company?

We are a manufacturer, and we have a foreign trade department, we market our own products.

3.What products can you provide?

We mainly produce beverage production machinery and equipment.

4.What are the application fields of your products?

Our products are mainly used by beverage factories /Beer brewing /Food packaging machinery or individuals who want to run a milk production plant.

5.Can you provide custom products?

Yes, custom products are our main products. We can develop and manufacture products according to customer's drawing or sample. Saving customer's time on finding corollary equipment.

6.How's your production capacity?

Our annual output is about 800,000 sets.

7.How many employees do you have?

We have over 100 employees, including several technicians and engineers.

8.How do you ensure your product quality?

We conduct inspections in every production procedure, and for finished products, we will take 100% inspection depend on international standards according to customer's requirements.

9.Payment?

We will confirm the payment with you when quoting, like FOB, CIF, CNF or others.

In batch production, we accept 30% deposit, balance against the copy of B/L.

T/T is the main payment, and L/C is acceptable as well.

10.What's your delivery method?

We commonly use sea transportation, using container to deliver the goods through Shanghai Port.

11.Where do you mainly export your products?

Our products are mainly exported to Mexico, Saudi Arabia, India, Algeria, Dubai, Congo, African countries, etc.

Trade Information

1. Package- all equipments packed in nylon cloth and plastic film worthy of sea shipping.

2. Delivery- in 30 days upon receipt of down payments.

3. Warranty-all machines & equipments are of one year warranty and life long maintenance offered by seller.

4. Installation- the seller arrange engineer to set up the equipments and train the operation workers for free, till qualified products are produced and maintenance in normal running, the buyer bear the round air tickets and local accommodation for the seller's engineer.