The process of PVC pipe production line

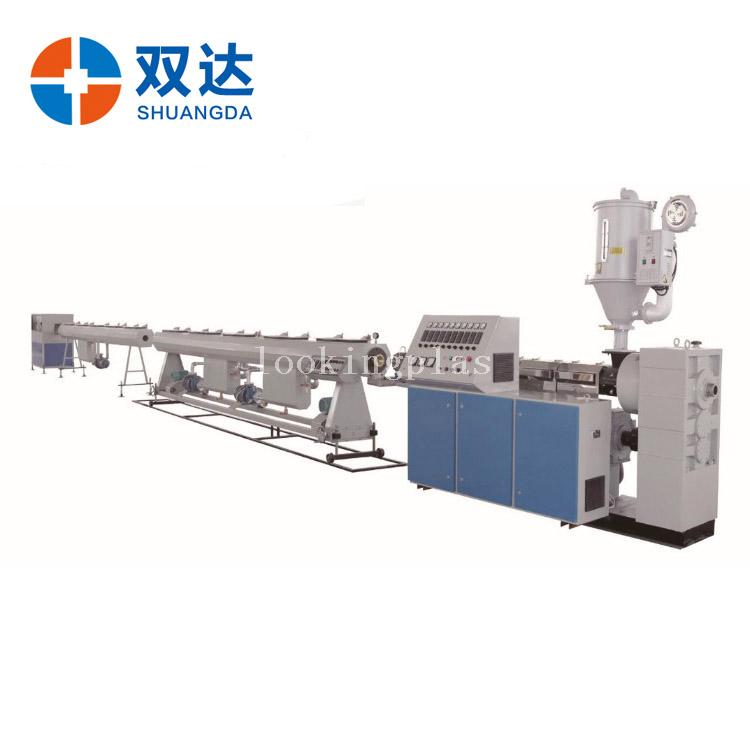

Production process material+Fertilizer preparation→Mixing→Conveying material→forced feed→Single screw extruder→Mold extrusion→Sizing sleeve→Spray vacuum setting box→Track dragger→Automatic cutting saw→ Pipe stack rack.

Equipment function of PVC pipe production line.

Raw materials mixing: PVC stabilizers, plasticizers, antioxidants and other excipients, in accordance with the proportion, the process has been added to high-speed mixer, by material and mechanical self friction, the material is heated to the set process temperature, the material is then reduced to 40-50 degrees by a cold mixer, so that it can be added to the hopper of the extruder.

Extruder part: the machine is equipped with quantitative loading device, the squeeze in and add the shoes to match, to ensure that products stable extrusion. Due to the characteristics of the conical screw, charging period has larger diameter, the material of the heat transfer area and the shear velocity is large, is advantageous to the material plasticizing, metering section of the screw diameter is small, reduces the heat transfer area and the shear rate of melt, can make the melt at lower temperatures extrusion screw within the barrel rotates, the plasticizing PVC mixture into the nose, so as to achieve compaction melt mixing homogenization; The device and screw drive device of the exhaust dewatering can be adjusted by frequency conversion.

Extrusion die part: PVC with compacted melting and mixing, the following materials are pushed to the die by the screw, and the extrusion die is the closing part of the pipe forming

Vacuum calibrating tank used for finalize the cooling pipes, vacuum system for setting and cooling water tank on the vacuum system and water circulation system, stainless steel casing, circulating water spray cooling, vacuum calibrating device mounted on the tank moved back and forth and around high and low adjusting device manually.

The tractor is used to automatically extract the cooled hardened tube from the nose and frequency control.

Automatic cutting saws: according to the required length by travel switch control, automatic cutting, and delay the plane, the water production, cutting machine to pronounce long switch signal instructions, complete the whole cutting process in cutting process and pipe running in sync, cutting process completed by electric and pneumatic drive, cutting machine is equipped with suction device, sucked out cutting the debris in a timely manner, and recycling.

Turn rack material movement by cylinder by pneumatic control, is expected to set up there is a limit device, when cutting saws cutting pipes, pipe to transport, after a delay, cylinder into the work, to achieve double material movement, the purpose of discharging the delay for a few seconds automatically reset after discharge, waiting for the next cycle.

Order Guide:

1. Ship date: 30----120 working days

2. Payment terms: T/T or L/C

3. Full range of devices to be provided on schedule, as per client demands.

4. Responsible for training technicians and operators for operation and maintenance of the equipment.

5. Responsible for installing and debugging all devices.

6. Formula available and long term technical supports.

7. Guarantee: One year guaranteed repair and lifelong tracking service,with parts provided.

8. All the parameters of the machine on metric units and in English.

9. Package: standard export wooden pallet.

How to get the quick and exact quotation?

Please tell me the following information :

1. The size (length, width, thickness of one side or two sides) .

2. The material

3. The style of the pipe, hose, bar , sheet, or the profiles

4. The quantity

5.If possible please provide the picture or the sample of the products.

Can you design for us?

Of course.We have a professional team having rich experience in plastic extruder design and manufacturing.

Please tell us your resquest such as the output and the voltage. Then we will help to carry out your idesa into perfect Plastic or Rubber extrusion machine.

Are you factory or trading company?

Definitly a factory .We have 19 years experience of producing Extrusion machine. We have our own factory , production line and workers .We have been certified by ISO9001.

How do you guarantee the quality of your company?

Quality assurance: committed to providing products and services that meet customer needs and requirements; Through continuous improvement of products, processes, service quality, improve customer satisfaction. "honesty and trustworthiness, quality first, customer first" purpose, continuous development and innovation, dedicated to serving our customers!

Quality system: Shuangda machinery has been certified by ISO9001 quality management system. It has a perfect after-sales service team and has done a lot of basic work for the development of future projects.

How to use extruder correctly and reasonably?

The production capacity of each machine should be matched so that the equipment of the production line can work harmoniously.

The size of the extruder should be selected according to the specification of the product.

Should be equipped with a skilled technical operator. Have a skilled operation skills and know how to maintain the equipment.

The extruder should be safe, reliable and grounded, and the equipment should be moisture-proof and corrosion resistant.

Question of warranty period

We are very confident in our products,and we pack them very well,so usually you will receive your order in good condition.

But due to long time shipment there will be very few damage for the extrusion equipment.Any quality issue,we will deal with it immediately.

Hebei Shuangda Rubber & Plastic Machinery Co.Ltd is a modernized company.Our company do R & D, production together, produces rubber, silica gel products, sales complete sets of plastic and rubber extrusion machinery. Our company is located in Liyuantun Industrial Park of Wei County, southeastern Hebei province with superior geographic position and convenient transportation. Company currently has employs 120 people, among which there are 30 technicians and 8 senior engineers. The professional technical team guaranteed products’ stable and technical performance. Our main products include extrusion equipments such as rubber extruder, production line of rubber tube extrusion, production line of three composite vulcanization, silicon vulcanization production line, production line of plastic sealing strip, production line of plastic pipe and elastomeric extruder. We also produce the production equipments of engineering sealing, automobile sealing, cable & wires, air-conditioning rubber tube, braided tube, automobile oil tube as well as water stop belt, etc.

Through insisting on the principles of “Customer-centric, Honesty and reliable” and regarding equipment quality as enterprise life, we provide high quality equipments and services as well as all-around technical supports for our customers.

We sincerely invite domestic and overseas customers come here to visit our company and discuss business. We are looking forward to cooperating with you on a long-term basis and create a win-win bright future together.

WeChat: 18875768789

Facebook: https://www.facebook.com/Shuangda-Rubber-Plastic-Machinery-COLTD-Hebei-Province-China-1752085085086667/

Tel: +86 18875768789