Disk Screener for PET Bottle Recycling System

Sieving machine is used to separete solid waste such as sand, metal, small stone, labels in PET bottle recycling process. It helps the PET bottle washing by reducing equipment abrasion, material loss to enhance productivity. Flakes sieving improve the quality of final PET flakes.

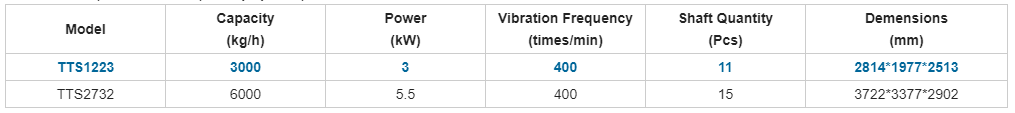

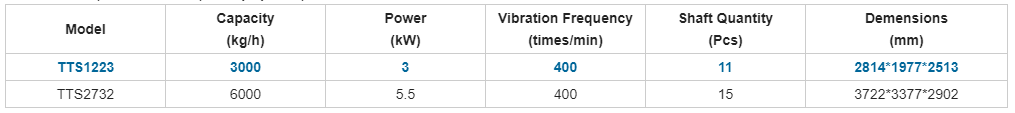

BoReTech supplys two types of sieving machines, dry trommel and disk screener. Disk screener is more compact than the dry trommel, it can be placed after de-baling and pre-washing then remove sand, labels and so on. It can evenly disperse the bottles onto the next process and remove remained water. Dry trommel can remove caps and sands separately by multiple mesh sizes.

More details, you can also send enquiry to our sales mail: sales@bo-re-tech.com

Standard Process Flowchart for Your Reference (Process as per layout based on customer's factory and rPET flakes applications demand)

De-baling------Metal Separation------ Label Scrapping------- Label Separation-------- Presorting------Bottle Pre-washing ------Automatic Sorting/Manual Sorting -----Wet Grinding-------Drying-------Hot Flotation-------Friction-------Continuous Rinsing-----Drying--------Dust Removal------Packing

Sieving Section

Sieving unit including dry trommel, disk screener and metal removal device to separate some big impurities such as mud, sands and metals from PET bottles and flakes. Meanwhile, through digital technology likes metal detector, pipe-type metal separator, metals can be separated automatically by flapping device to reduce inline manpower. Besides, belt-type metal separator can reach the same function.