25L, 30L, 50L,60L HDPE Drum Extrusion Blow Molding Machine Plastic Jerry Can Making Machine,60L automatic jerry can bottles extrusion blow molding machine,Lubrication Oil Barrel/Bottle/Jerry Can Making Machine blow molding machine,automatic extrusion plastic blow molding machine jerry can, plastic jerry can single station extrusion moulding making machine hdpe bottle jerrycan blow molding machine,Plastic Jerry Can Single Station Extrusion Moulding Making Machine Hdpe Bottle Jerrycan Blow Molding Machine, jerry cans,HDPE Accumulating Plastic Drum Moulding Jerry Can Blow Molding Machine Price,plastic drum blow molding.

20-60Liter Extrusion Blow Molding Machine:

1. Double stations or single head

2. Layers:1-3layers

3. Two platens with arm toggle clamping structure, liner guide way for clamping and moving;

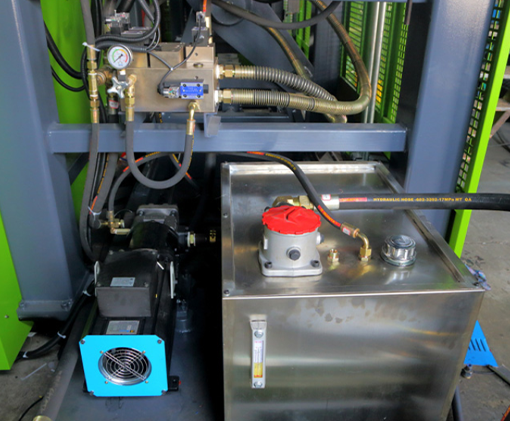

4. With lubrication system;

5. Power supply: 380v/50hz/3ph (depending on clients requests);

6. Automatic deflashing design, saving labor cost;

7. Environment friendly design.

Plastic Jerry Can Making Machine is accumulating extrusion blow moulding machine for 60L as maximum, specially used for 20~60L jerry can/plastic drum and barrel, Its production capacity for 25L jerry can is more than 50 Pcs/hour, for 50L open-top drum is 33 Pcs/hour. jerry can drum blow molding machine is popular due to its wide products application range, stable working performance, easy operation and maintenance.

SPECIFICATIONS & TECHNICAL DATA |

Extrusion Unit | Screw Diameter | mm | 90 |

Plasticizing Capacity | Kg/hour | 140 |

Temperature Control Zone | No. | 5 |

Accumulating Head | Accumulating Head Volume | L | 5 |

Max Ejection Weight | KG | 3.8 |

Max Product Net Weight | KG | 2.5 |

Max Die Diameter | mm | 400 |

Clamping Unit | Clamping Force | KN | 360 |

Platen Size | mm | 800x900 |

Opening Distance | mm | 400~1050 |

Max Mould Thickness | mm | 600 |

Max Mould Size | mm | 750x1400 |

Driving System | Extrusion Motor Power | KW | 37 |

Pump Motor Power | KW | 22 |

Machine Total Power | KW | 102.5 |

Average Power Consumption | KW | 28.5 |