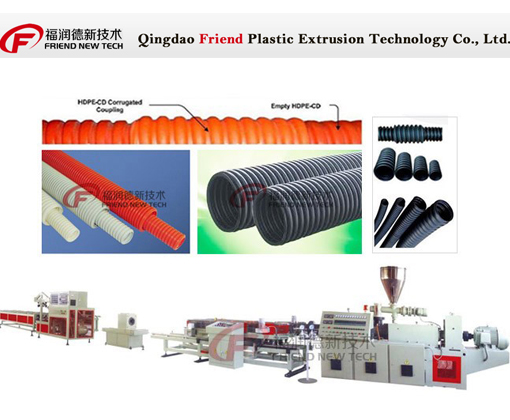

Description of PE/PP/PVC Single Wall Corrugated Pipe

Manufacturing Equipment:

Introduction of PE/PP & PVC Single Wall Corrugated Pipe Production

Line

It consists of automatic feeding system/single screw extruder/die

head/forming machine /winder. It is mainly produce PE/PP/PVC single corrugated

pipe. The PE/PP/PVC single corrugated pipe is mainly used in the golf course,

playgrounds as light load of drainage, floods; Interior decoration cable casing;

Automotive wire casing; The washing machine, air conditioner drain; Prestressed

concrete special pipe, etc.

Features of PE/PP/PVC Single Wall Pipes:

1). It has good

flexibility: to resist distortion, bending good performance Acid, lubricating

oil, cooling fluid, etc

2). Exterior luster, friction resistance

3).

Carrying capacity is strong, can bear the weight of the foot, doesn't break,

deformation, can quickly recover, and itself without any damage

Features of PE/PP Single Wall Corrugated Pipe Production Line:

1). Adopt Electric-magnetic heater which can save 40% to 60% electric energy

.

2). All electric parts ( breaker/relay/ inverter ) is

SIEMENS/SCHNEIDER/OMRON

3). PLC control and simple operation

4). The

forming machine has 38 pairs to 72 pairs forming block.

5).Production speed

is 15m/min to 25m/min.

Technical Parameter of PE/PP/PVC Single Wall Corrugated Pipe

Machine:

Model | Pipe Diameter (mm) | Motor Power | Speed (m/min) | Max .Output (kg/h) | Total Power |

FSJ-45X30 | 5-15 | 15 | 1-20 | 45 | 35 |

FSJ-50X30 | 16-32 | 18.5 | 1-15 | 90 | 55 |

FSJ-65X30 | 40-63 | 37 | 1-10 | 120 |

|