Description of 3PE Anticorrosion

Steel Pipe Production Line:

Introduction of 3PE Anticorrosion Steel Pipe Extrusion Machine:

3PE

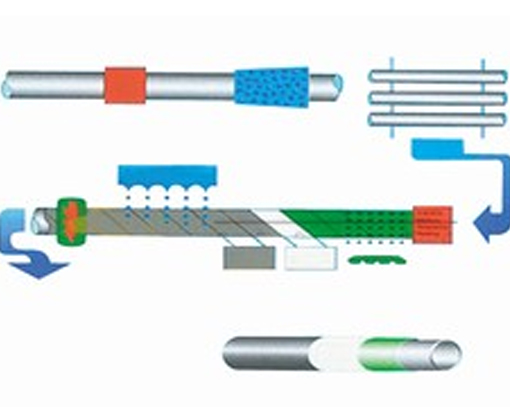

Steel Pipe anti-corrosion Production Line includes as following process

flowing:

Steel tube inspection--Steel tube surface skim-- Steel tube

intermediate frequency preheating Peen-forming degusting --Internal and external

dust sweep-- Degusting check --Dust processing→Medium frequency induction

heating-- Epoxy powder coating-- AD adhesive coating --PE coating --Inspection.

3PE Anti-corrosion steel pipe is widely used in oil pipelines, natural gas

pipeline, heating pipe, water supply pipe.Characteristics of 3PE anticorrosive steel tube:

1) polyethylene

anticorrosion properties is admirable, but tolerance in the natural environment

of the existence of the various corrosion;

2) high quality and price

ratio;

3) polyethylene insulating performance is wonderful, and in dry

conditions and long-term immersion electrical performance under the condition of

basic unchanged,can effectively prevent the stray current corrosion caused by

electrochemical;

4) microbial corrosion resistance and deep roots plant thorn

ability, won't happen plant roots through phenomenon;

5) high strength, can

be directly with contain more than Φ 25 mm in diameter of the artificial pieces

of gravel soils and not cause any damage to backfill;

6) coated tubes overall

flexural ability, generally allow cold bending 1.5 tube diameter;

7)

production process for all mechanized, stable product quality, be helpful for

the comprehensive quality control;

8) polyethylene coated steel pipe

production of all raw materials for the production of large enterprise, a

reliable source, quality assurance;

9) long service life and can be used in

more than 50 years.

Features of 3PE anticorrostion coating machine:

1. Peen-forming derusting equipment . The function is mainly clear rust of

steel pipe surface.

2. Electric-magnetic heating equipment . It is Qingdao Friend Plastic

Extrusion Technology Co.,Ltd 's patent . It is compared with medium frequency

heating equipment .the electric-magnetic heating equipment has some advantages .

The first the heating speed of electric-magnetic heating equipment is faster

than medium frequency heating equipment . The second , if electric-magnetic

heating equipment is compared with medium frequency heating equipment , the

electric-magnetic heating equipment can save 40% to 60% electric energy

.

3.Epoxy powder thermal spray equipment . The function is mainly coat a

layer epoxy powder on the steel pipe surface . The function of a layer epoxy

powder prevent steel pipe oxidation. the thickness of epoxy powder is

(60—80μm).

4.Adhesive coating equipment . It include extruder and die head . the

extruder adopt electric-magnetic heater which can save 40% to 60% electric

energy for customer ! The function is mainly extrude adhesive. The thickness of

adhesive is (170—250μm);

5.Polyethylene coating equipment . it include extruder and die head . the

extruder use electric parts which brand is word famous brand. (

Siemens/Omron/Schneider ) . The function is mainly extrude Polyethylene. The

thickness of polyethylene is about 2mm to 5mm. Adopt electric-magnetic heater

which can save 40% to 60% electric energy for customer . Adopt PLC control and

simple operation .Material of screw and barrel: 38CrMoAlA, nitrogen quenched

which the thickness layer 0.4-0.7mm; Hardness of screw barrel: >940 HV;Unique

grooved structure feed bush with force cooling system that is specially designed

by Friend co. which can increase output at 15-20%; Material of die head is 40Cr,

the surface and channel of mould is chrom-plated;

6. Water Cooling Equipment. It includes motor/support/ vacuum pump/transport

devices. The function is cooling and transport 3PE anticorrosive steel tube

.

Technical Parameters of 3PE Anticorrosion Steel Pipe Machine:

Model | Pipe Diameter (mm) | Motor Power (KW) | Output (Kg/hour ) |

FSJ-80X33-400 | 100-400 | 110 | 350 |

FSJ-100X33-800 | 400-800 | 185 | 600 |

FSJ-120X33-1500 | 800-1500 | 250 | 900 |