1. Preparation of PTFE film

1.1 Choice of resin

The polytetrafluoroethylene (ptfe) film resin used for processing mutual inductor insulation shall be suspended resin with uniform molecular weight distribution and high crystallinity, generally with the crystallinity above 98 and molecular weight at 1O ~ 1O.The resin particle size is about 30t~m. PTFE of this specification is used to prepare PTFE film for mutual inductor insulation with excellent physical properties and excellent electrical properties.

Production process of ptfe film

(1) Pretreatment of PTFE raw material

PTFE suspended fine resin was placed in a constant greenhouse at 20℃ ~ 23℃ for 24 hours for pretreatment.

(2) Ramming and sifting

The pre-treated PTFE suspended fine resin was pounded and sifted by the rammer to make the resin loose for molding.

(3) The mold

Adopt cold pressing process method, add 10000gPTFE suspended fine material resin into the mold, press the blank with 20MPpa molding single pressure on the 100 ton automatic pressure machine, pay attention to exhaust during the pressing, and avoid the crack of the blank.

(4) Sintering

Put the pressed products into high temperature sintering furnace, to 50.C/h rate of temperature rise to 330℃, insulation for 3h, then at 30℃ / h rate of temperature rise to 380℃, insulation 1O ~ 14h, and then at 30~40℃ / h rate of temperature drop to 320℃, insulation for 3 ~ 4h, finally at 50℃ / h rate of temperature drop to 150℃, turn off the electricity natural cooling to room temperature, take out the product.

(5) Rotary cutting into film

The sintered preforms are turned into thin film preforms by special lathe. The membrane blank is 0.2mm×255mm×300m(thickness × width × length).

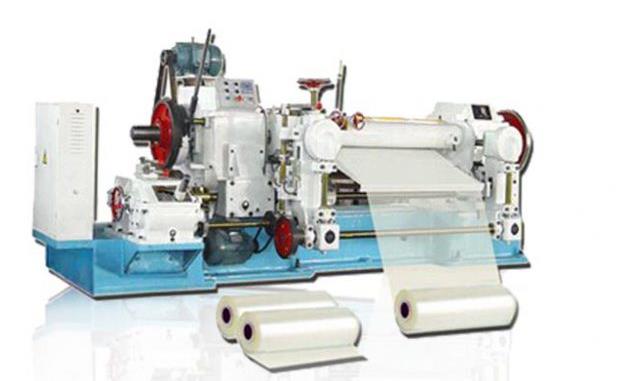

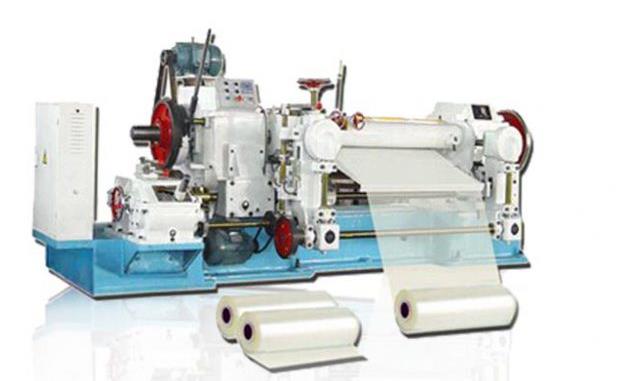

(6) Calendering orientation

After rotary cutting, the directional blank is processed by the hot roll directional calender (see figure 2), and the directional degree is 1.8 ~ 2.0. The thickness is 0.1mm directional film, hot roll temperature control in 15O℃ ~ 180℃.

(7) Cutting

Let’s make the thickness 0.1mm directional film with special cutting machine processing into 0.Ptfe film for insulation of mutual inductor 1mm×35mmx 450 ~ 500m(thickness × width × length).

(8) Inspection of packaging

Polytetrafluoroethylene (ptfe) film for insulation of the processed ct shall be sampled for internal performance inspection, and the appearance and size inspection of the film shall be conducted at the same time. PVC film bag shall be used for packaging of the products that pass the inspection, and inspection certificate shall be attached.

2.2 Performance index of PTFE film

In this experiment, PTFE films with different orientation degrees (orientation degree of material, whose value is the ratio of the length of film samples before and after heating) are compared with standard indexes in tensile strength, elongation at break, dc breakdown voltage intensity and other properties.

PTFE Film Machine Inquiry:

liuwei@plummytech.com / louis2008beijing@hotmail.com

Wechat/WhatsApp/Telegram:+86-15995994564

www.plummytech.com

arb.plummytech.com

fr.plummytech.com

ru.plummytech.com

pt.plummytech.com

thai.plummytech.com

turkish.plummytech.com

es.plummytech.com

ir.plummytech.com

il.plummytech.com

vn.plummytech.com