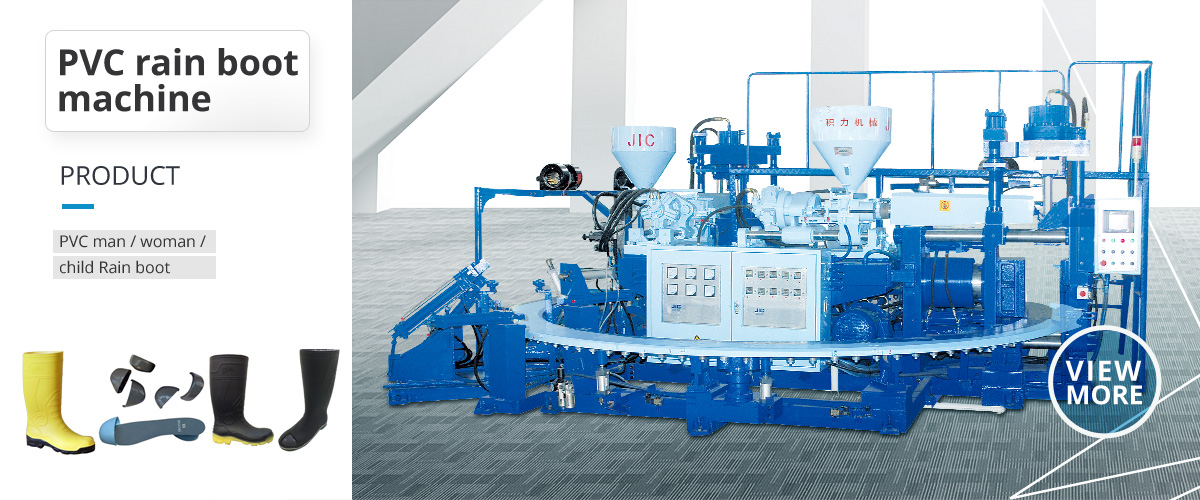

JIC612ASF Double Color Rain Boot Machine

Introduction

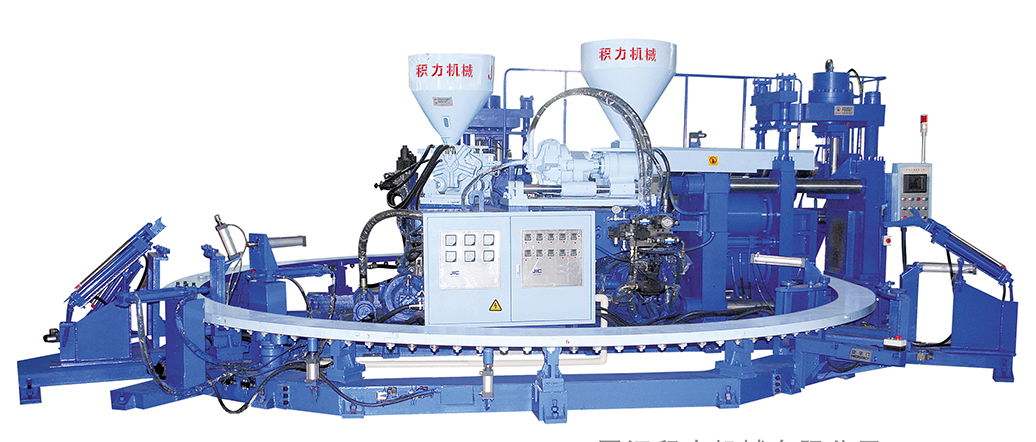

1. Components

The two-color rain boot injection machine is mainly composed of a clamping system, an injection system, a control system, a hydraulic system and a disc feeder.

2. Machine products

The products of the two-color rain boots injection machine are two-color PVC rain boots for adults and children and PVC safety rain boots (the height of the boots is less than 400mm)

Features

1. The two-color rain boot injection machine uses a human-computer industrial interaction interface. It is controlled by a PLC system and the information is displayed on a touch screen.

2. Pressure and flow are precisely adjustable in a double proportion hydraulic system. The accuracy of the data provides stability to the production process. Operating in the hydraulic system is easy and convenient.

3. The machine is designed for easy handling. It can even be used without professionals.

4. The mechanical arm of the water boot injection machine allows labor savings thanks to the fact that the entire process is automatic.

5. The variable pump and servomotor are offered to the customer. They save electricity since the variable pump of the two-color rain boot injection machine can reduce consumption by 25% and the servomotor by 35% (accurate data may vary)

Advantage

1. Our company sells a lot of two-color rain boots injection machines in China. This type of machines can produce two-color PVC rain boots for adults and children and PVC safety rain boots.

2. The closure system works with a single cylinder, which provides high pressure and well distributed products with small fins. You can opt for a servomotor for the rain boot injection machine, which helps reduce noise and electricity consumption by 30%.

Our company has developed a series of footwear manufacturing machines, including EVA foam injection machines, rain boots injection machines, air blow shoe machines, belt and upper injection machines, sole injection machines , injection machines for shoes, injection machines for sandals, auxiliary equipment for shoes and shoe molds in recent years.

Parameters:

Project | Unit | Specifications |

Model |

| 612ASF | 614ASF | 616HSF |

Raw Material |

| PVC | PVC | PVC |

Work station number | station | 12 | 14 | 16 |

Injection capacity(max) | cm3/cc | 1270,660 | 1270,770 | 1955,880 |

Injection Hydraulic | kg/c㎡ | 0-150,0-120 | 0-150,0-120 | 0-150,0-120 |

Heating Power | kw | 15+13 | 15+13 | 15+13 |

Limit of temperature | point | 5 | 5 | 5 |

Screw Speed | r.p.m | 0-150 | 0-150 | 0-150 |

Screw Diameter | mm | ¢90,¢70 | ¢90,¢70 | ¢95,¢75 |

Servo Motor Power | kw | 16.4*2;8.6 | 16.4*2;8.6 | 16.4*2;8.6 |

Clamping force | T | 250 | 250 | 250 |

Mold Size L*W*H(max) | mm | 680*420*200 | 680*420*200 | 680*420*200 |

Machine Size | mm | 6350*5260*2460 | 6750*5260*2460 | 6850*6000*2460 |

Gross Weight | kg | 18700 | 19500 | 20000 |