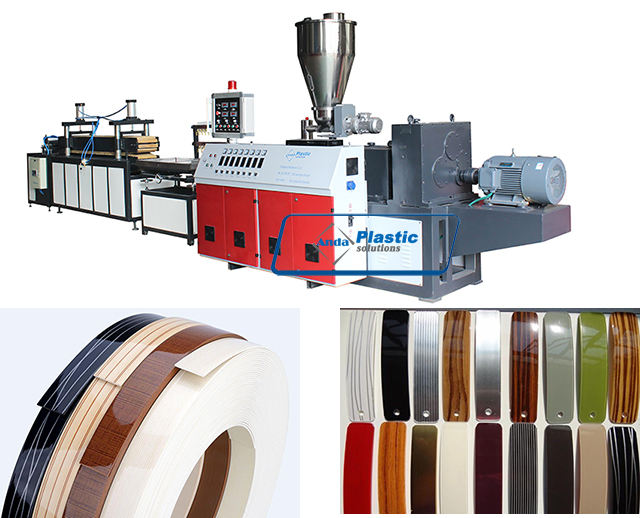

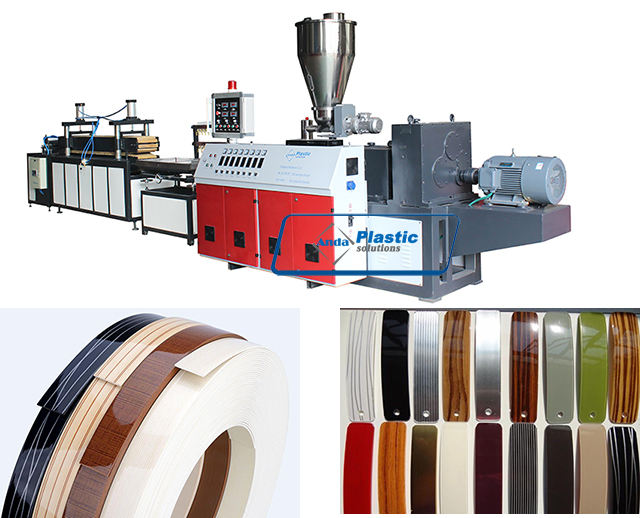

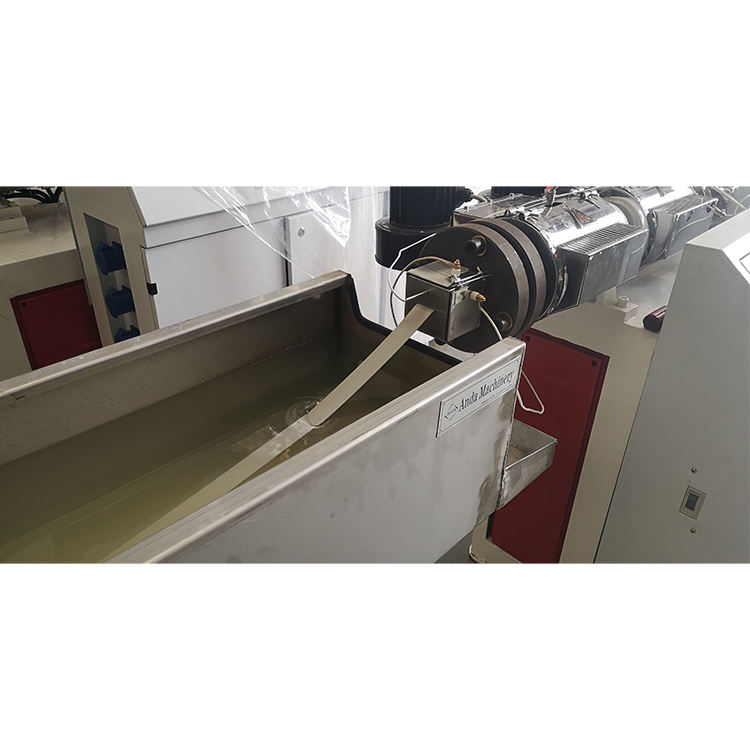

PVC edge band production line

Furniture PVC ABS PMMA edge banding making machine /PVC edge band production line /extrusion machine

PVC edge band making machine is used to produce PVC edge band which is popular used for the cross section of furniture plate for protection, decoration. We can make the size of 19-54mm width and 0.4-2mm thickness. The surface of PVC edge band is treated by printing. By switching printing roller,the surface of PVC edge band can get different design.

We can use single screw extruder or double screw extruder to produce PVC edge band according to customer requirement.

Three ways ofpvc edge banding tape Production Line / edge band making machine:

1. Mixer+ PVC granulating machine+single screw extruder+printing machine

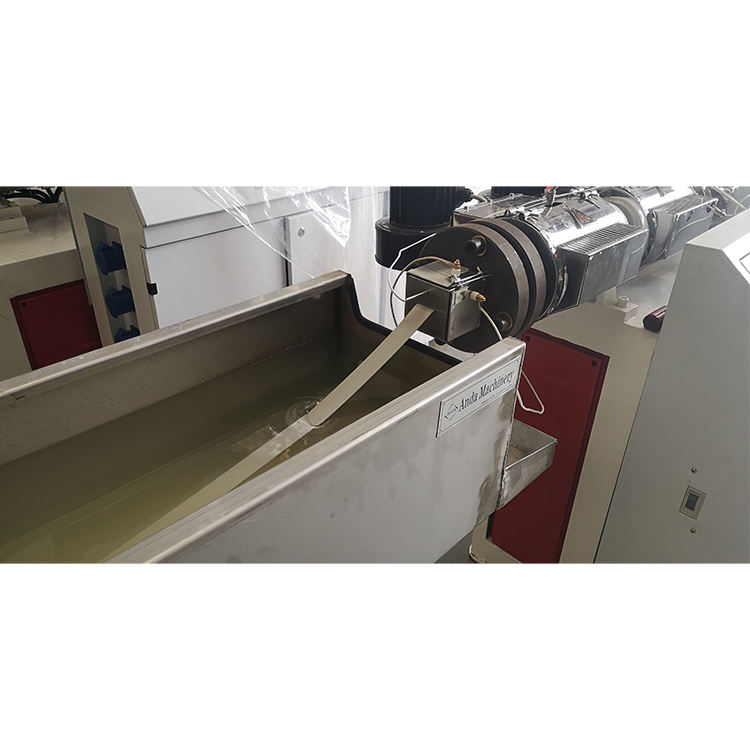

Process: First you need mix raw material together by PVC mixer, second make granule by granulating machine, and then Use single screw extruder(Sj45 or SJ65 single screw extruder) to get edge band, then use printing machine to get glossy surface or wooden design and etc.

Model and parameters:

| Model | Extruder model | Mould Cavity | Max Output(kg/h) | Drive Motor Power(kw) |

| SJ45 | SJ45 | Single | 700kg/day | 11kw |

| SJ65 | SJ65 | Double | 1200kg/day | 15kw |

2. Mixer+Double screw extruder+ printing machine

Process: First mix raw material together by mixer, and the use double screw extruder(SJSZ51/105 or SJSZ55/110) to produce egde band, final step is to print color or make edge band glossy.

Model and parameters:

| Model | Extruder model | Mould Cavity | Max Output(kg/h) | Drive Motor Power(kw) |

| SJSZ51 | SJSZ51 | 6cavity | 2200kg/day | 15kw |

| SJSZ65 | SJSZ65 | 8cavity | 3500kg/day | 22kw |

3. Three calender system+ printing machine+cutting machine:

First mix raw material, and then use three calender system to produce big width edge band sheet, and then print colors on the edge band, finally, cut pvc edge band sheet into specific width like 19mm, 20mm etc...