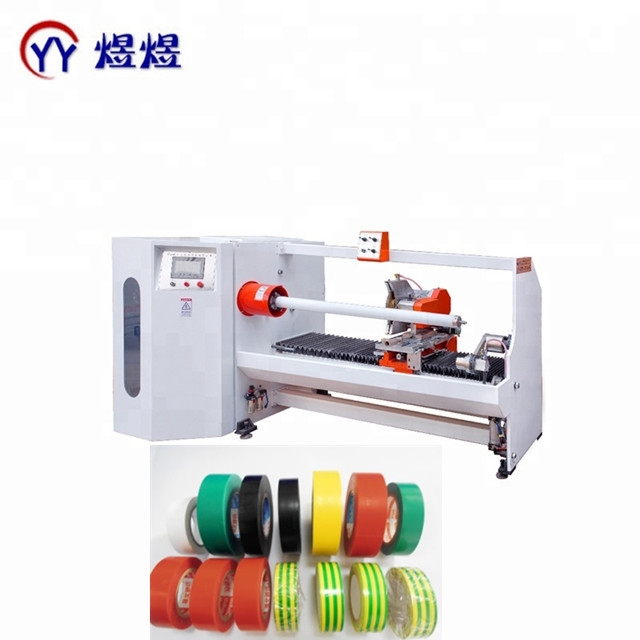

Suitable for cutting various log roll materials such as Insulation tape/polyester tape/

PVC/OPP/PE/Masking tape/Double side tape/Plastic films/windows film

/3M tape/fiberglass mesh tape…etc.

Technical parameters:

|

Max. cutting diameter

|

150mm

|

|

Max. cutting speed

|

25cuts/min

|

|

Max. length of cut

|

1300mm/1600mm

|

|

inside diameter of paper core

|

1 inch

|

|

cutting width

|

1-1600mm

|

|

main motor

|

5HP

|

|

blade drive motor

|

3HP*6P(servo motor)

|

|

blade diameter

|

200mm

|

|

blade speed

|

360-1800rpm

|

|

weight

|

1.5T

|

|

machine dimension(L*W*H)

|

2850*1430*1520mm

|

Raw Materials:

Features:

Features:

(Optional:safe cover)

1. Centralized control panel: all operation controls. For this machine are centralized

in a control panel.

2. Control panel provides major functions: material and blade running speed

(LED screen display), width counter, number of cuts counter.

3. Silicon lubricating system prevents the blade from sticking on adhesives and

allows smooth cutting at all times. Silicon liquid is re-circulated.

4. The blade is back pressure controlled through an air and hydraulic combination,

giving maximum cutting stability and fast blade retract after each cut,

cutting pressure can be easily adjusted to suit various types of materials.

5. Cutting circular knife and main shaft power force adopted with AC step-less

adjusting motor and available in any rotating direction.

6. Cutting width setting up controlled by servo motor adjustable equipped with ball

screw to secure accurate size.

7. PLC programmable control.

Detailed Image

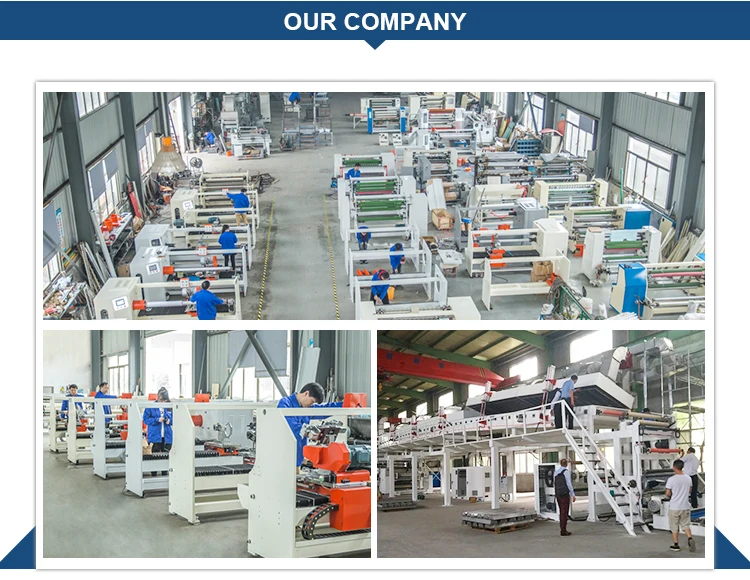

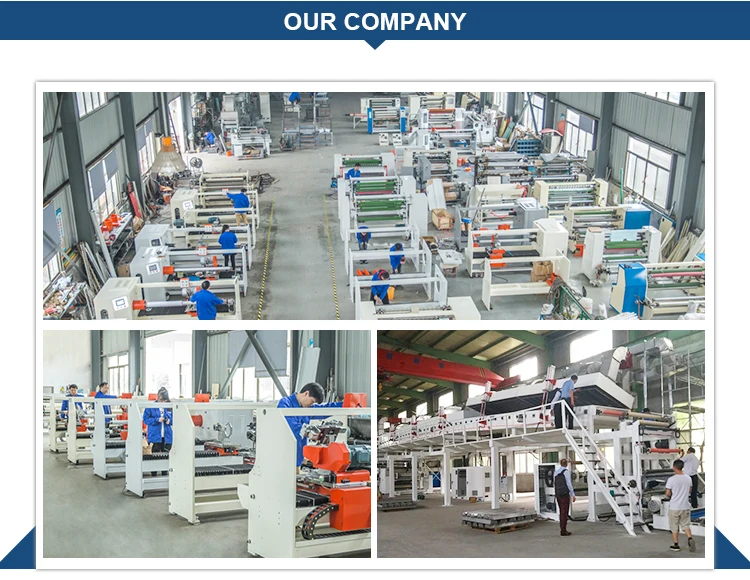

Company Profile

Yu Yu Plastic Co., Ltd is located in China Tape Technology Industry Park, Taicang City, Jiangsu Provience where is near to Shanghai City .The company is a professional manufacture of adhensive tape device after the Steel Machinery. We provide professional technology, perfect service,so that every customer can feel free to buy and feel comfortable to use.

The company is a research and development, design, production, sale , trade in one large multi-functional integrated modern enterprise, which specializing in automatic rewinding machine,slitting machine,cutting machine,manufacturing machines for tape.

With a coating machine,slitting machine,cutting machine prototype,ready and waiting for your visit.Customers are free to choose the style,working site to customize and have a train operation for you. Zhao Manjun, the general manager has the experience for many years to solve your questions on technology,production and operation in 24 hours.carton sealing or fixing kraft paper tape cutting machine

Certificate

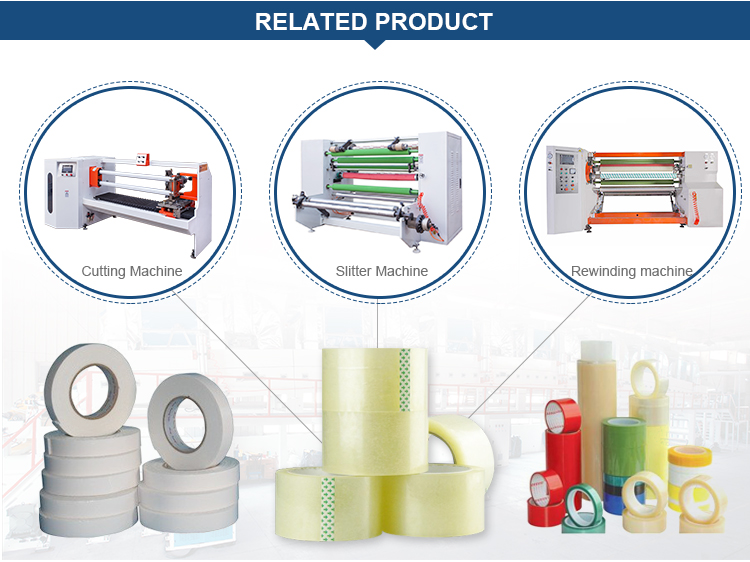

Related Products

If your jumbo roll diameter is large,need YU-806 rewinding machine,rewinding big diameter jumbo roll to small diameter,then cut on cutting machine get small tapes.

Packaging & Shipping

Packaging Type: Case, Film

Packaging Material:Wood , Plastic

Shipping Port : NormallyShanghai Port Also Can According To Your Demands

FAQ

1)Q: Are you trading companies or manufacturers

A: We are a manufacturer located in taicang city,jiangsu province,China.With 20 years of industry experience,we welcome customers to visit our factory.

2) Q: What are your main products?

A: Our company is a professional manufacturer of adhesive tape and whole plant equipment.Main production glue, coating,rewinding, cutting, packaging and other special equipment.We also offer custom services

3) Q: What are the raw materials?

A: Bopp film&adhesive glue &paper tube

4) Q: What is your equipment advantage?

A: All outsourcing products will be supplied by well-known suppliers, and the equipment will be tested well before delivery

Customers can visit the equipment or take their materials for testing

5) Q:What is the expected life of Motor and other parts?

A:The host equipments are entitled to one year warranty&free replacement&life time technical support service

whatsApp:+8613902480274