ETFE film characteristics

1. Good transparency;

2. Although ETFE films have elasticity, they still have structural resistance;

3. Durable and long-lasting;

4. ETFE film has approximately 70% acoustic transmission;

5. Easy to recycle, ETFE membrane is a recyclable material that can be reused to produce new membrane materials, or to separate impurities and produce other ETFE products.

ETFE film application

(1) Water treatment industry: removal of suspended solids and small particles in water;

(2) Electronic industry: semiconductor industry ultra pure water, integrated circuit cleaning water terminal treatment;

(3) Food industry: removal of yeast and mold from alcohol and beverages, clarification and filtration of fruit juice;

(4) Chemical industry: filtration and clarification of various chemicals.

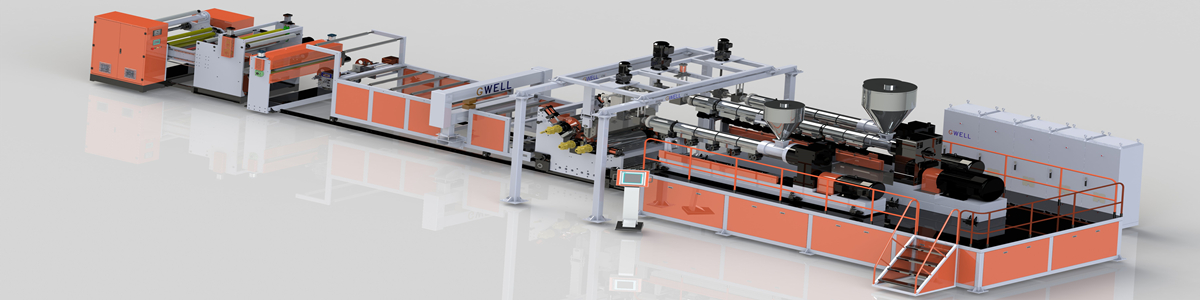

Introduction to ETFE Film Production Line

1. An extruder made of special high-temperature and corrosion-resistant steel is used to achieve stable extrusion of fluoroplastics;

2. Design screw structures and die structures based on the special characteristics of fluorine materials, and combine them with special molding, winding, and other processes to achieve rational, factory based, and large-scale production of fluorine plastic products;

3. The whole machine has a high configuration, practical and reasonable design, PLC touch screen control, and whole machine interlocking control, which is convenient and stable.

Main parameters of ETFE film production line (please consult sales engineer for details)

| Host type |

Single screw extruder |

Single screw dual machine co extrusion |

| Product type |

Single layer structure |

A;A/B; A/B/A structure |

| Product width |

1250-2200mm

|

1250-2200mm

|

| Product thickness |

0.02-0.1mm

|

0.02-0.1mm

|

|

output

|

120-180kg/h

|

140-200kg/h

|

| Linear velocity |

30m/min

|

30m/min

|