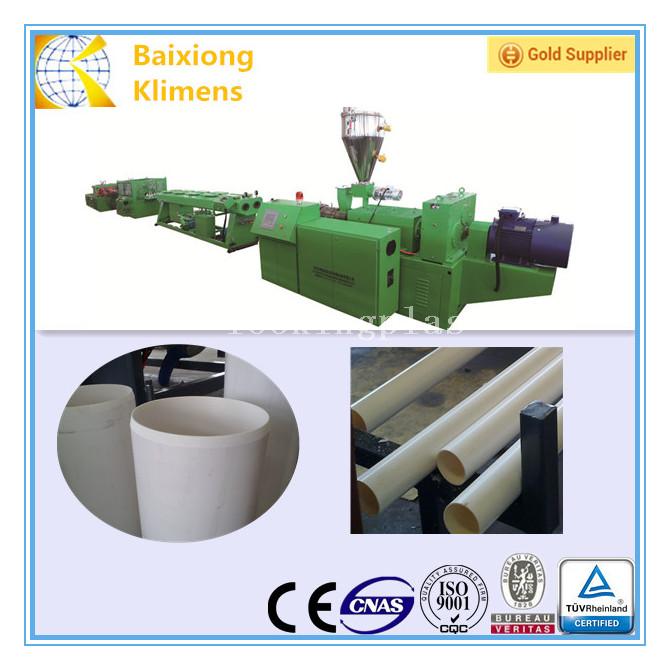

SJSZ Series PVC pipe making machine

PVC Pipe Production Line :

1) It is mainly used in the manufacture of PVC pipes with various diameters and wall thickness in the aspects such as the agricultural and constructional plumbing, cable laying etc.

2) The set is composed of conical twin-screw extruder, vacuum calibrating tank, haul-off, cutter, stacker or belling machine etc.

3) The extruder and haul-off machine adopt the imported AC frequency control device.

The vacuum pump and hauling motor employ superior goods.

4) Haul off machine of different specifications, such as two caterpillars, three caterpillars, four caterpillars, six caterpillars etc are designed for different requirements.

5) It is additionally attached with length measuring apparatus and thickness increasing device.

6) The unit is of reliable performance and high production efficiency

3. PVC Pipe data:

Item | Machine | Quantity |

1 | Spring loader | 1 set |

2 | Conical Twin-Screw Extruder SJSZ With control panel | 1 set |

3 | Double-extrusion die and head, for pipes 16~650mm as required wall thickness | complete set |

4 | Double Chamber Vacuum Calibration tank | 1 set |

5 | Ink-jet printer for twin pipe printing ( two spray heads ) | 1 set |

6 | Double Hauling & Cutting Machine Combination | 1 set |

7 | Stacker for twin pipe | 1 set |

PVC pipe extrusion line Characteristics

1. Suitable to U-PVC,C-PVC,M-PVC pipe

2. Optional to adopt conical twin screw extruder or parallel twin screw extruder

3. Supply formula guide and staple raw material purchase

PVC pipe extrusion line Application:

PVC pipe machine are interested by most customer in recently years.

It is estimated PVC pipe production line will have a potential huge market in plastic machinery. This

PVC pipe used widely.i.e. water supply and drainage,liquid gas and oil transportation,sewage and building

industry.

PVC pipe extrusion line Processing flow:

Material →Mixer →Forced feeding →conical double screw extruder →mould & calibrator → vacuum spay

cooling tank →printer → haul-off →cutter →stacker

Descriptions of PVC pipe extrusion line

Conical twin screw extruder:

Conical twin screw special for PVC powder.

Screw inner temperature control: screw inner core constant temperature device.

Control system adopts SIEMENS PLC,FUJI/ABB/OMRON electrical instruments ensures the stable running.

Special screw design ensures the high efficiency extrusion, flexible plasticization and super-high output of PVC material. The design of screws can provide high-speed cutting and mixture for polyolefin material during the process. The special cooling way can prevent the obstruction of material caused by the transportation of heat. Special cooling accessory is installed in ‘reduced speed’ box to lower the high temperature caused by high-speed teeth of screws. Then the good quality and high capacity can be obtained.

PVC extrusion mould & calibrator :

Innovative spiral flowing structure avoids fuse mark appearance on the bigger pipe, profile of ideal dwell time is full of the whole flow cross-section, Homogeneous melt distribution with selective temperature control guarantees outstanding product characteristics for PVC materials. Design of flow channel can avoid the dead spots and stagnation zones. Spiral channel increase the heating area of material, lower the melting temperature. Large-volume flow channel have equality pressure of melting, decrease the pressure loss. Mandrel design with rigid construction, avoid floating.

Easy assembly / disassembly.

Vacuum calibration tank:

Vacuum calibrator is made by stainless steel plates. The metal pipes (inside and outside) use stainless

steel pipes. With plastic adjustable sprayer and various internal pipes for adjusting the direction, the

vacuum pressure inside can control the temperature and level of water, which can be controlled by setting system too.

Spray cooling tank:

Spray cooling bath is made by stainless steel material. Transparent soft PVC films are installed on both

sides, can be pull up for easy control. Six rows of sprayers are inside and guarantee the surface of

pipes having enough cooling. Internal water temperature control system provides suitable water

temperature. Two-channels can keep normal production during the clean up of channel.

Hauling unit:

The haul-off units designed for polyolefin pipes have different clipping power referring to

different pipe sizes. The haul-off units can be designed in double-belts, triple-belts, four-belts,

six-belts, etc. The belts have independent moving system and the clipping power is controlled by air

pressure. Belts are following the direction of nylon slides. Stable with less vibration. Made in good

materials and can be durable.

Cutting machine:

Planetary saws for polyolefin pipes cutting. Full-hydraulic design ensures flexible pressure in cutting

state of pipes, unique power input system ensures high reliability of planetary unit, with ultra silent

& enforced sucking system, auto angle chamfer function. The saws are made in platinum steel. Different

clipping system is used for different sizes of pipes to guarantee the stability of pipe cutting. We use

Siemens PLC control system to provide an accurate cutting.

Technical Parameters of PVC pipe extrusion line:

Follow standard diameter scope as below sheet, flexible to user's reasonable requirement

PVC,PE,PP Pipe Production Line

Extruder

Baixiong Klimens’s single screw extruder of polyolefin pipe production line is specialized designed for

polyolefin products. The design of screws can provide high-speed cutting and mixture for polyolefin

material during the process. The special cooling way can prevent the obstruction of material caused by

the transportation of heat. Special cooling accessory is installed in ‘reduced speed’ box to lower the

high temperature caused by high-speed teeth of screws. Then the good quality and high capacity can be

obtained.

Certificate