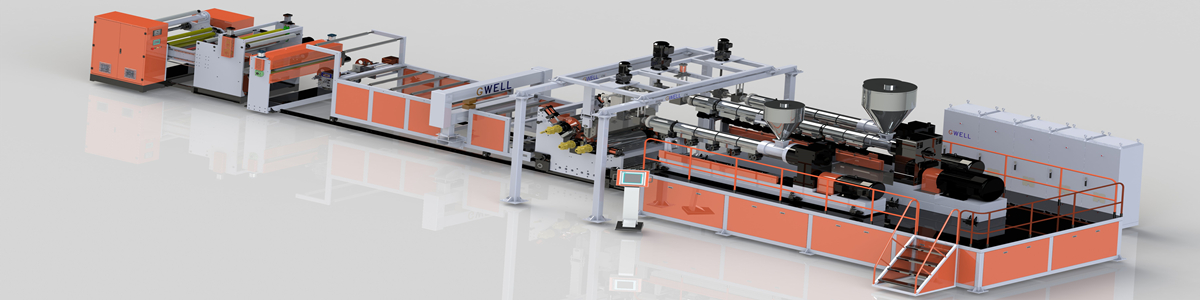

The PMMA transparent plate production line of Suzhou Jinweier Machinery Co., Ltd. fully absorbs and digests European and American extrusion technology. The main components are selected from European products (such as screws, barrels, rollers, etc.). The energy consumption, intelligence, automation indicators, safety standards, process standards, etc. of the complete equipment have reached or are close to the standards of European products

The PMMA transparent sheet production line is mainly used to produce polymethyl methacrylate (PMMA) transparent sheets, which are commonly referred to as organic glass. These sheets have high transparency, good stability, and strong weather resistance, and are commonly used as glass substitute materials. The following is a detailed introduction to the PMMA transparent sheet production line:

1、 Characteristics of production line

Automated control: PMMA sheet production lines commonly use automated control systems, which can significantly improve production efficiency and product quality.

Good plasticizing effect: The production line equipment has excellent plasticizing ability, ensuring the uniformity and consistency of the board.

Large production capacity: The production line design is reasonable and can meet the needs of large-scale production.

Low energy consumption: Advanced energy-saving technologies are adopted to reduce energy consumption during the production process.

2、 Composition of production line

Raw material preparation and mixing:

Select high-purity and high transparency PMMA raw materials to ensure the quality and optical performance of the board.

Mix PMMA raw materials with other additives, pigments, etc. in proportion to prepare a mixture that meets the requirements.

Extruder:

The extruder is one of the core equipment of the production line, responsible for heating and extruding the mixture into a sheet shape.

The design and parameter settings of the extruder have a significant impact on the quality and performance of the sheet metal.

Mold:

The mold is used to determine the shape and size of the sheet metal.

The accuracy and lifespan of molds have a significant impact on the quality of sheet metal forming.

Cooling and cutting:

The extruded sheet needs to be cooled and solidified to ensure its dimensional stability and performance.

After cooling, use cutting equipment to cut the sheet into the required specifications and sizes.

Surface treatment:

Polish and coat the surface of the board to improve its surface quality and optical performance.

3、 Application Fields

PMMA transparent sheet is widely used in fields such as optics, home appliances, and construction engineering. For example, in the field of optics, PMMA sheets can be used to make optical components such as light guide plates and lenses; In the field of household appliances, PMMA sheets can be used to make the shells and panels of refrigerators, washing machines, and other household appliances; In the field of construction engineering, PMMA sheets can be used to make building materials such as skylights and partitions.