Product Overview:

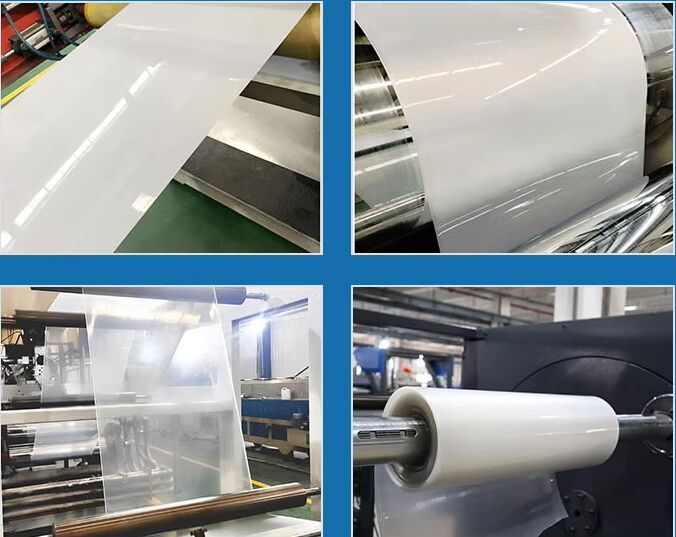

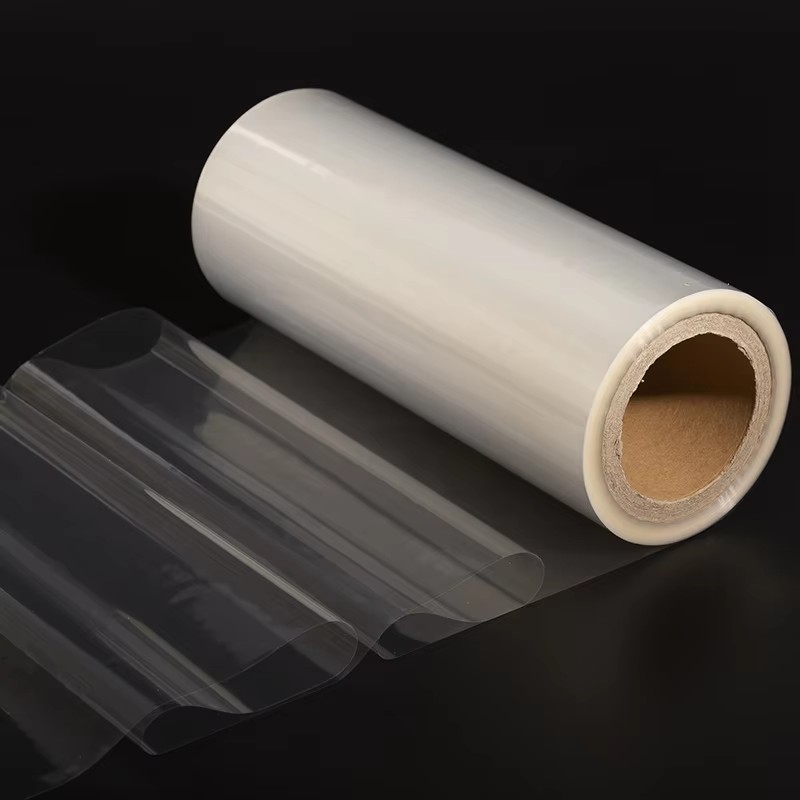

PET, PLA plastic sheet is widely used in food, pharmaceuticals, toys, electronics, gifts, clothing, stationery and other fields because of its high transparency, good mechanical properties, and non-toxic and odourless environmental protection features, but the moisture-absorbing properties of PET may reduce product quality in the extrusion process, the single-screw model has a high-efficiency vacuum venting capability, and the melting temperature curve is accurate, the melt is well dispersed.

Product features:

1. Special twin-screw double-exhaust structure can fully exhaust the gas and volatiles in the material from the plasticised material;

2. Maintaining good mixing effect and plasticising quality of the material, which can maximally improve the quality of the products and reduce the processing defects of the products;

3. No need for pre-drying, significantly reducing drying costs;

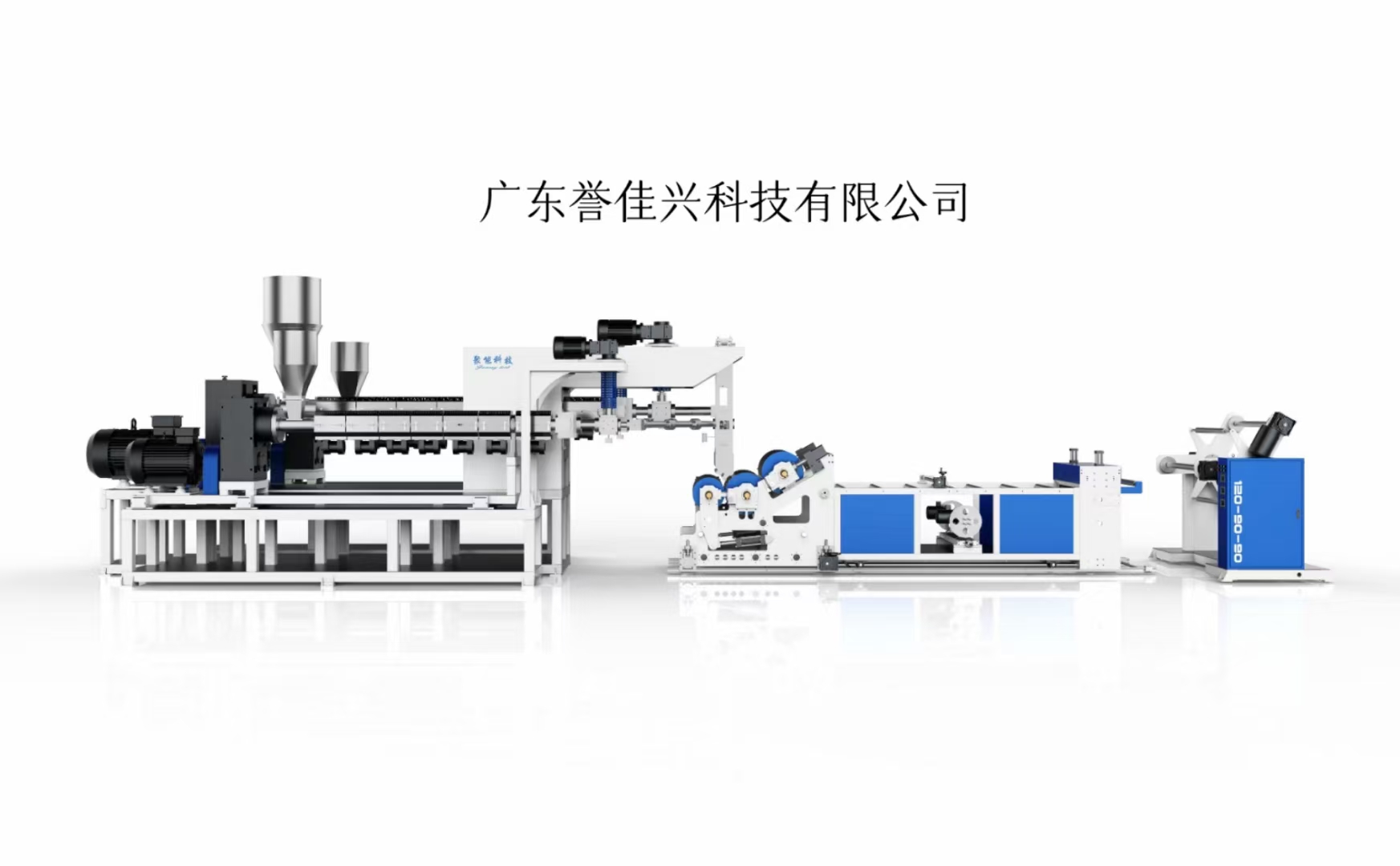

4. Modular design, compact structure, easy to operate, simple maintenance;

5. It can realise on-line crushing of edge material, automatic change of rolls and rewinding, improve product quality and reduce cost;

6. Using advanced electronic software system, parameter setting, data computing, alarm and other automation functions, the operator's safety and labour intensity has been greatly improved.

Maximum total power (kW)

Dimension (Mm)

|

Model

|

JNW120-1200

|

JNW130-1200

|

JNWG120/75-1200

|

|

Material

|

PP/HIPS/PE

|

|

|

|

Maximum Capacity (Kg/h)

|

400-500

|

600

|

450-550

|

|

Plate Thickness (mm)

|

0.3-2.0

|

0.3-2.0

|

0.3-2.0

|

|

Thin Plate Layer

|

A

|

A

|

ABA

|

|

Screw Diameter (mm)

|

φ120

|

φ130

|

φ120/φ75

|

|

Paper Width (mm)

|

≤800

|

≤800

|

≤800

|

|

Maximum Total Power (kW)

|

250

|

315

|

280

|

|

Dimension (Mm)

|

15000*4500*3700

|

16000*4500*3700

|

150000*6000*3700

|