Wicket bags with bottom gusset/Courier poly bag/Square bottom bread bag/Round bottom chicken bag

1. Hanger hole puncher device

2. Chicken bag puncher device

3. Bottom pre-heat device

Servo motor:Yaskawa Japan

Inverter: Yaskawa Japan

Photocell: Datalogic Itlay

PLC control: Panasonic Japan

Certification: CE/ISO:9001

Fully Automatic Servo Motor Drive Wicketer Bag Making Machine

This machine is specially designed for making side hole bag, fully automatic. It shows the best technic of servo motor and the latest type of mechanism structure. In addition, it has the excellent speed of 350pcs/min.

Main Features

1. Special servo motor driving

2. With printing tracking photocell use Datalogic, from Italy

3. Rotary-arms unit for collection of bags

4. Double swing arm dancing, it is suitable for high speed feeding, the film will not shake.

Optional Equipment

1. Hanger hole puncher device

2. Chicken bag puncher device

3. Bottom pre-heat device

Technical Parameter

| Type |

CW-800BFS、CW-800bfs (meta ) |

| Length of bag-making |

300-700mm |

| Width of bag-making |

100-250mm |

| Bottom gusset |

30-70mm |

| Speed of machine |

250pcs/min |

| Total Power |

About 22KW |

| Weight of machine |

2200KG |

| Dimension of machine |

8000*2800*1950mm |

| Air compressor ( not included ) |

7.5HP |

Main Part

Automatic hydraulic loading unwinder

Hydraulic lift unwinder Automatic tension control EPC system & triangle folder

|

bottom gusset device

Bottom gusset, the maximum gusset depth 60mm

|

Printing Image Tracking

With printing tracking photocell use Datalogic, from Italy, zero malfunction, sealing and cutting correct.

|

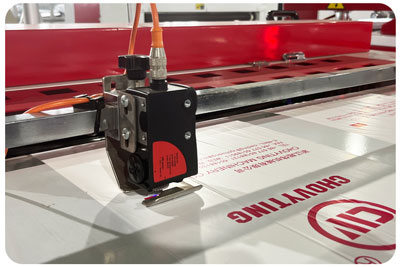

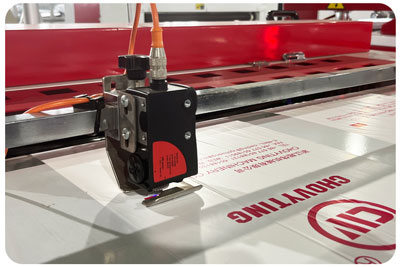

Hanger hole punch unit

equipped with EPC, is able to move synchronized with collecting pins

|

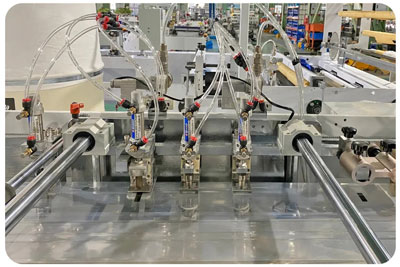

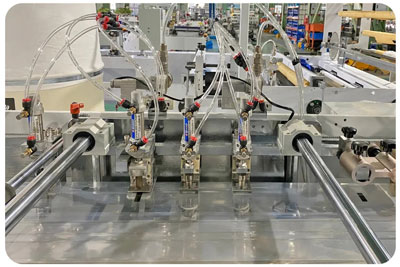

Chicken bag punch

To make round bottom chicken bags, can be exchange with square bottom punch for making bread bags

|

Rotary Arms (wicket part)

To save human labor cost of collecting bags & enables the machine to run at high speed

|