Home > Product

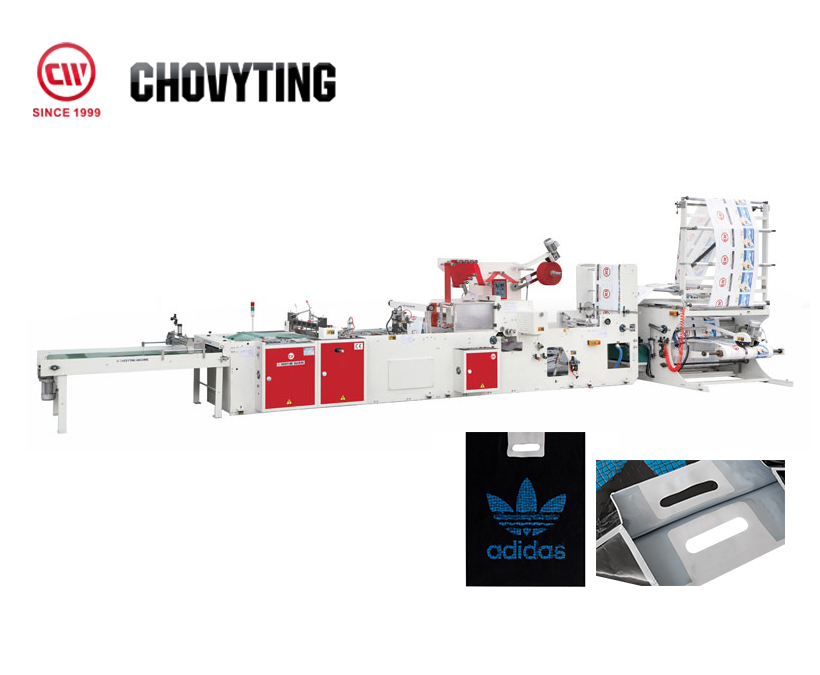

Categories > CW-800NJT Fully Automatic High Speed Inside Glue Patch Handle Bag Making Machine

CW-800NJT Fully Automatic High Speed Inside Glue Patch Handle Bag Making Machine 161 Favorites

| Product Categories: Sealing and Cutting Bag Making Machine | |

| Packaging Details: | Trademark: |

| Certification: CE, | |

| Payment Terms: | |

| FOB: USD $/ | HS Code: |

| Loading Port: | |

| ZHEJIANG CHOVYTING MACHINERY CO., LTD. | |

|---|---|

| Company type: Manufacturer | Credit:

|

| Main products:Bag Making Machine | |

Contact Supplier

Reminding

Message has been sent successfully.