2 functions (patch handle bag, die cut handle bag)

1. side sealing knife

2. Folding unit

3.Automatic collect table

Servo motor:Yaskawa Japan

Inverter: Yaskawa Japan

Photocell: Datalogic Itlay

PLC control: Panasonic Japan

Certification: CE/ISO:9001

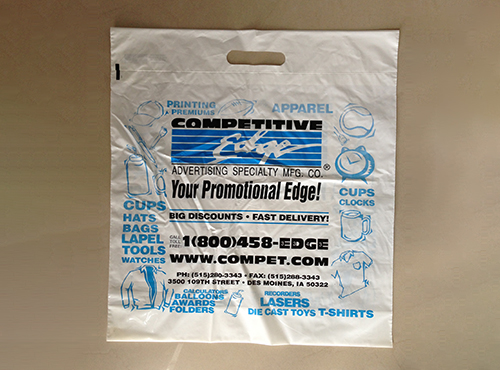

Fully Automatic Patch Handle Bag Making Machine

This machine has 2 functions (patch handle bag, die cut handle bag. It is coupled with machinery ,light ,electronic and pneumatic. CW-800SP Full automatic patch handle / die cut handle plastic shopping bag making machine

Brief introduction:

This machine has 2 functions ( patch handle bag,die cut handle bag). It is coupled with machinery, light, electronic and pneumatic.

Including:

1. side sealing knife

2. Folding unit

3.Automatic collect table

OPtional equipment:

1.Single sheet film fold unit(hydraulic auto loading device)

2.Double sealing knife device

3.Bottom sealing knife device

4.Triangle folding device

|

Model

|

CW-800SP

|

|

Length of bag-making

|

250-750mm

|

|

Width of bag-making

|

250-800mm

|

|

Top-folding edge

|

50-75mm

|

|

Bottom gusset

|

20-70mm

|

|

Speed of bag-making

|

|

Soft loop handle bag

|

|

|

Patch handle bag

|

80pcs/min

|

|

Poly draw handle bag

|

|

|

Die cut handle bag

|

80pcs/min

|

|

Total power

|

10KW

|

|

Machine weight

|

3200kg

|

|

Machine dimension(LxWxH]

|

8x

3.1x

1.87m

|

Details Images

|

|

Common unwinding

1. Unwinding adopt common loading , max diameter of raw rolling materialisφ600mm

2. Adopt magnetic powder tension control. Manual adjust the tension.

3. Unwinding shaft is heavy-chainplug axle

|

Top-folding continuously sealing device

1. Top-folding continuously sealing, the width size of bag not be limited,

2. Inside heating wire sealing, which is suitable for full colors of bag.

3. Adopt import heat wire, steady warming, hard sealing

|

|

|

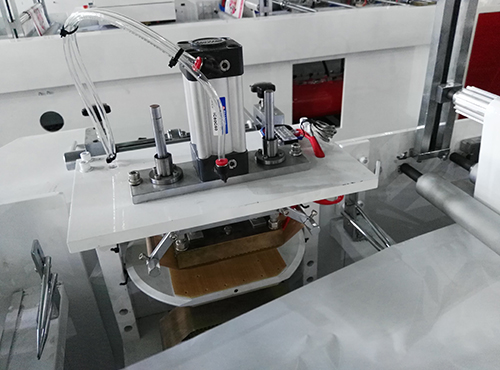

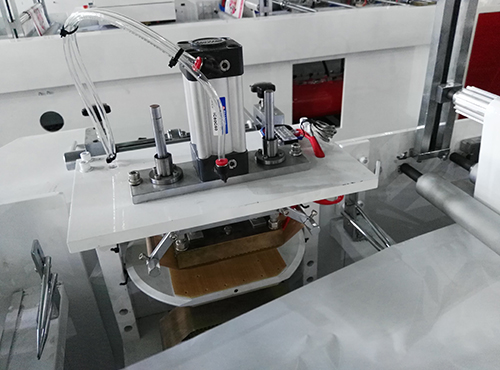

Patch handle bag device

1. Turnabout cylinder control patch

2. With flying knife cutting fast

3. Special pattern sealing mould

4. Micro-motor driver patch go forward and back off

5. Base mould of patch device adopt whole steel plate

|

|

|

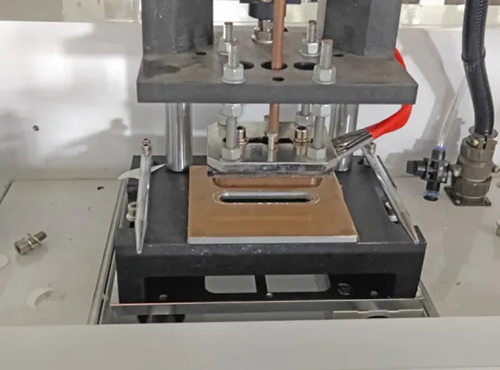

Heat sealing handle punch

1. High hardness gear steel smooth pillar

2. Air outside waster film blower hopper

3. The whole style rotary 180 degree

4. High hardness alloy aluminium puncher base plate

|

|

|

Side sealing parts

1.Side sealing knife with water cycle cooling system.

2.Side sealing knife adopt best of breed material, high temperature heating ametabolic.

3. Side sealing knife with concealed style heating tube, temperature steady

|

Convey collect device

1.Collect table adopt automatic collecting bag feeding (intermission model and continuum model)

2.When the bag reach to a certainty quantity, collect table will move automatically, and continuo producing.

3.Collect table is driven by Micro-motor reducing servo

|