Product Description

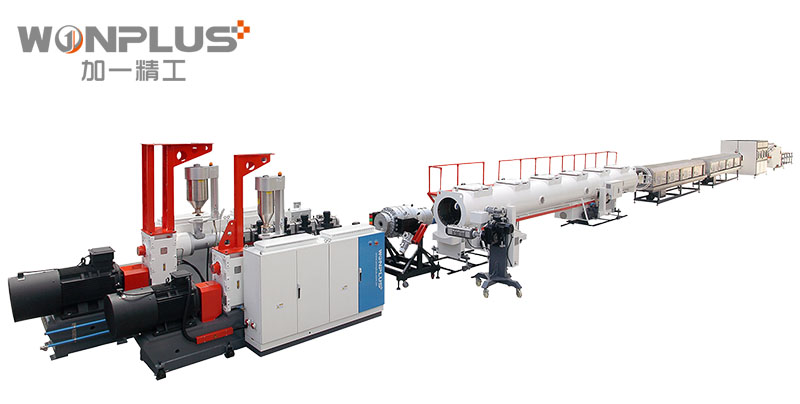

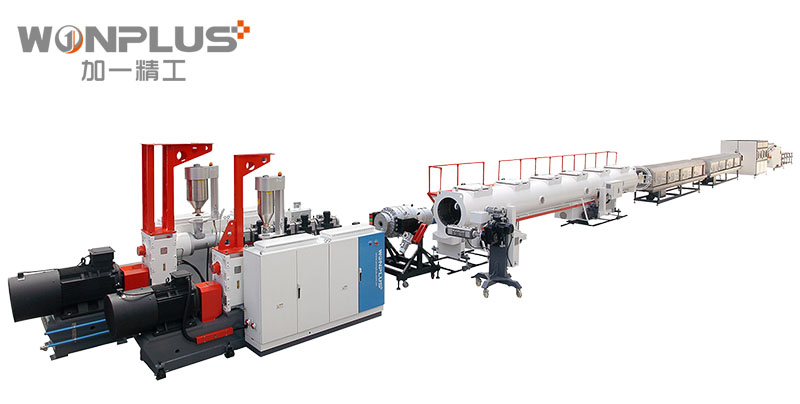

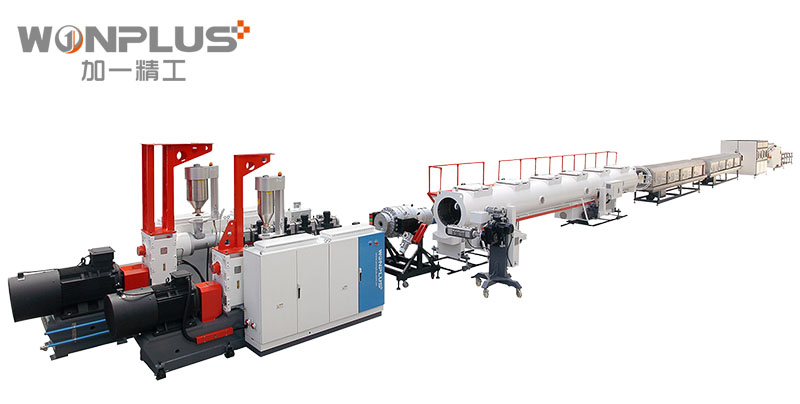

The production line is characterized by high productivity, high efficiency, high automation, etc. The operation and time of the production line are programmed and controlled by PLC, and all the process parameters can be set and displayed through the touch screen.

Equipment Composition: Single Screw Extruder (2 or 3 sets) + Co-extrusion multi layers pipe mould + Vacuum calibration tank + Water cooling spraying tank + Caterpillar type Hauler + Dust-free Cutter + Stacker/Winder

Application: PE/PPR multi-layer pipe extrusion line is used for the production of telecommunication pipes, indoor hot or cold water pipes and chemical pipes.

Line Main Parts

|

Single Screw Extruder

Driven motor: Siemens brand

Temperature control: Siemens computer

Inverter: ABB brand

Cotactor & Relay: Schneider brand

Circuit breaker: DELIXI

|

|

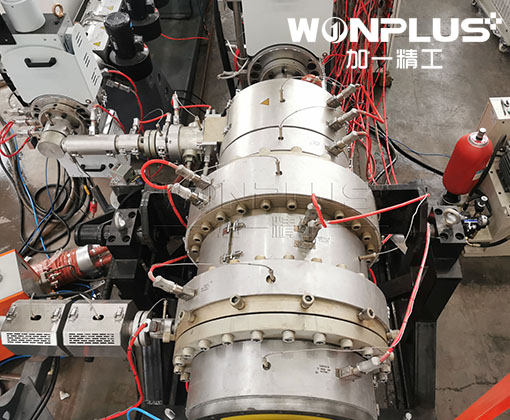

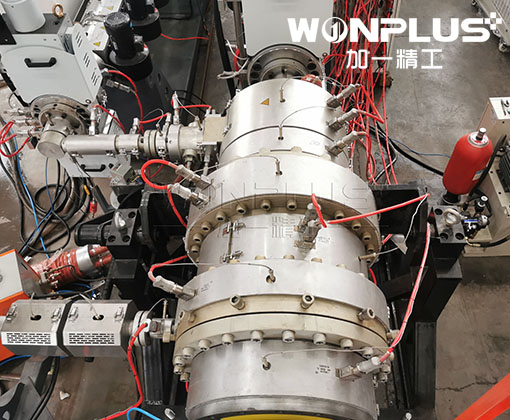

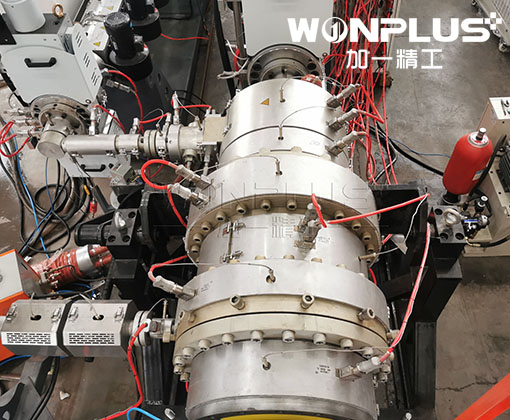

Extrusion Mould

Material: 40Cr

Calibrator: Stainless steel

The inner flow channel is plated with hard chrome, the outer surface is treated with high temperature paint, the corrosion resistance is strong.

|

|

Calibration Tank

Material: Stainless steel

Tank Movement :

Forth and back by motor driven

Up and down by food screw adjust

|

|

Spraying Tank

Material: Stainless steel

Length: 6m or customized

|

|

Hauler

Traction motor reducer: Servo motor, INNOVANCE brand

Electricity components: Schneider brand

|

|

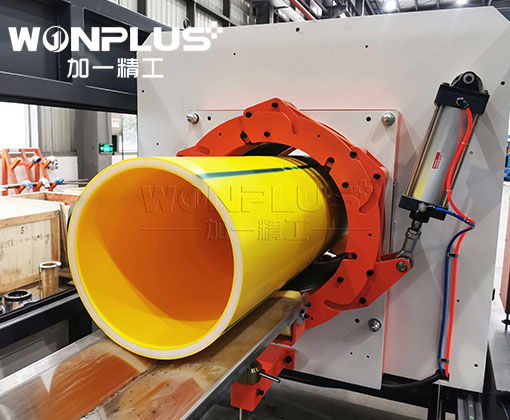

Cutter

Cutting control: SIEMENS PLC computer

Cutting type: Planetary saw cutter, Non-dust cutter

|

|

Stacker

Humanized design, labour-saving

|

Packing and Delivery

Contact Information

Bella Miao

+86-18100698105 (Whatsapp / Wechat)

Email: sale7@wonplus.com.cn

Kunshan Oneplus Machinery Co.,Ltd.

ADD: No. 17 Xi Wei Rd,Qiandeng,Kunshan City,Jiangsu Province

www.won-plus.com

www.facebook.com/wonplusmachinery

---Specialized In Plastic Extrusion Machinery---