The PVC ultra transparent door curtain production line is centered around single screw extrusion and three roll calendering, with a focus on high transparency, softness, and cold resistance. It is suitable for low temperatures of -30 ℃ and is widely used in cold chains, clean workshops, supermarkets, and logistics channels. The following provides an explanation of equipment composition, key process points, specifications and production capacity, selection and application.

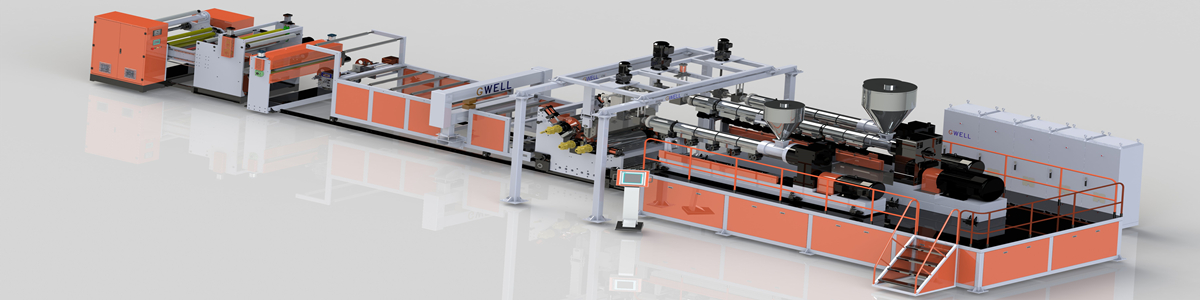

Core equipment composition

Single screw extruder: SJ75/SJ90/SJ120, exhaust type, L/D 28–33:1, Vacuum feeding, temperature control ± 1 ℃.

Screen changer: Quick screen changer, optional melt metering pump, stable extrusion.

Mold head: hanger type/T-shaped elastic mold mouth, double section flow, width 150-600mm, thickness 0.4-4mm.

Three roll calender: vertical/oblique 45 °, roller temperature control, calendering and shaping.

Cooling and trimming: cooling bracket+trimming knife, temperature control by water temperature machine.

Traction and winding: Rubber roller traction, dual position inflatable shaft winding, stable tension.

Electrical and auxiliary: PLC+frequency conversion, raw material drying and scrap recycling.

Key points of process

Raw materials: PVC resin+plasticizer+stabilizer+transparency agent, moisture content<0.05%, dry at 80-100 ℃ for 2-4 hours.

Extrusion temperature: barrel 160-190 ℃, die 170-200 ℃, to avoid degradation and crystallization.

Polishing and cooling: The roller temperature is 40-60 ℃, and the cooling bracket water temperature is 20-30 ℃ to ensure transparency and flatness.

Traction and winding: Traction ratio 1:1.2-1:2, uniform tension, winding diameter ≤ 1.2m.

Specifications and Capacity

Model width (mm) thickness (mm) production capacity (kg/h) applicable scenarios

SJ75 200-400 0.5-3 150-180 Small and Medium Batch

SJ90 200-400 0.5-3 200-250 medium batch

SJ120 200-600 0.8-4 300-400 Large Batch

Selection key

Capacity matching: Select models based on daily production and reserve 10-20% margin.

Transparency and Cold Resistance: Choose an exhaust type extruder, high transparency formula, and high-quality stabilizer to ensure a light transmittance of ≥ 85%.

Thickness accuracy: Equipped with online thickness measurement and automatic thickness adjustment, with a tolerance of ± 0.02mm.

Environmental Protection and Compliance: Food/Medical grade 304 stainless steel contact parts are required, and electromagnetic heating can save energy by more than 30%.

Application scenarios

Cold chain and cold storage: -30 ℃ cold resistance, cold and hot insulation, insect and dust prevention.

Cleanroom: Class 10000 cleanliness, zipper track+magnetic sealing, suitable for pharmaceuticals/electronics.

Supermarkets and logistics: high transparency, fast opening and closing (0.6-1.5m/s), reducing energy consumption.

Industrial partition: wear-resistant, acid and alkali resistant, wind resistant ribs enhance stability.

Common Problems and Countermeasures

Insufficient transparency: Optimize the formula, improve plasticization, and reduce cooling water temperature.

Surface crystal points: Strengthen drying, replace filter screen, clean mold head.

Uneven edges: Adjust the gap between the mold mouth and optimize the traction tension.

Poor cold resistance: Use low-temperature resistant plasticizers and cold resistant formulas.

Quick configuration suggestions

Small and medium-sized batch: SJ75+hanger mold+three roll calendering+dual station winding, with a production capacity of 150-180kg/h.

Medium batch: SJ90+melt metering pump+online thickness measurement, with a production capacity of 200-250kg/h.

Large scale: SJ120+internal cooling system+automatic thickness adjustment, with a production capacity of 300-400kg/h.