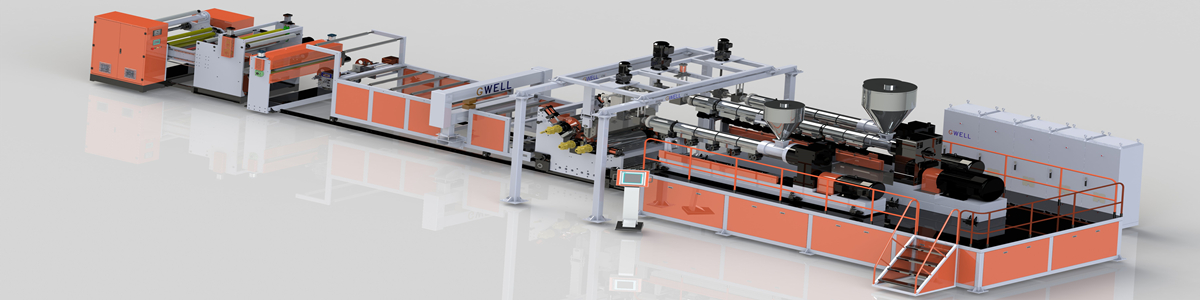

The TPU casting film production line is a specialized equipment for producing TPU films through extrusion casting cooling shaping process. Compared with the blown film process, the film produced by it has the advantages of high thickness uniformity, fewer crystal points, and smooth surface. It is suitable for various production needs such as single-layer and composite, and is widely used in medical, shoe materials, electronics and other fields. The following provides a detailed explanation from the aspects of equipment composition, core process points, specifications, production capacity, and application scenarios:

Core equipment composition

Extrusion system: The core is a single screw extruder, and some high-end production lines can be matched with multiple extruders to achieve co extrusion. The screws are mostly designed in sections, with a length to diameter ratio of usually 28-33:1, suitable for TPU high shear stress extrusion needs, and are divided into multiple temperature control zones for precise temperature control. Equipped with a hydraulic screen changer to filter impurities in raw materials, and partially equipped with a gear metering pump to stabilize the melt conveying pressure and ensure uniform extrusion volume.

Casting molding system: The mainstream adopts an internal blocking hanger type die head with a double section flow design, which can ensure uniform film thickness and online adjustment of product width. Some equipment is also equipped with a laminating device, which can meet the composite requirements of simultaneously laminating release films, attached fabrics, and other materials on both upper and lower layers.

Cooling and shaping system: Common three roll or five roll cooling devices, with precision machining of the inner wall of the roller, and a roller temperature control accuracy of ± 1 ℃. The unique cooling and tempering process can quickly reduce the temperature of the film, avoid film deformation, and ensure its flatness and transparency. Some production lines will also be equipped with cooling brackets to assist in shaping.

Traction and winding system: The traction machine adopts materials such as rubber rollers to ensure that the film surface is not damaged during traction, and the traction speed is accurately matched with the extrusion speed; The winding equipment is mostly a dual station winding machine, controlled by servo motors to prevent bubbles and wrinkles during winding. The winding diameter can usually meet the needs of industrial conventional coil materials, and some equipment is also equipped with a waste edge winding device to reduce raw material waste.

Auxiliary and control system: including dehumidification dryer and vacuum feeder, used for drying TPU raw materials (to avoid high water content causing bubbles in the film); Siemens PLC is commonly used for electrical control, which can achieve full system automation control. Some equipment is reserved with remote control ports, supporting remote synchronous monitoring, and only one person is needed to complete the control. Simultaneously equipped with an online thickness gauge, real-time monitoring of film thickness and feedback adjustment.

Key process points

Raw material pretreatment: TPU raw material has strong moisture absorption and needs to be dried at 80-100 ℃ for 2-4 hours to control the moisture content below 0.05%. Otherwise, it may cause defects such as pinholes and bubbles in the film, affecting product quality.

Accurate temperature control: The entire line is divided into multiple temperature control zones. The melting temperature of the barrel is usually 170-210 ℃, and the temperature of the mold head is slightly higher than that of the barrel, controlled at 180-220 ℃, to avoid TPU degradation and yellowing caused by high temperature, or insufficient plasticization and crystallization caused by low temperature.

Cooling and tension adjustment: The temperature of the cooling roller is generally controlled at 40-60 ℃, and the cooling speed needs to be matched with the extrusion speed. If it is too fast, it can easily lead to a decrease in the toughness of the film, while if it is too slow, it will affect the shaping effect. When pulling and winding, the tension needs to be kept constant, and the pulling ratio is usually controlled at 1:1.2-1:2 to prevent excessive stretching of the film from damaging the molecular chains and affecting elasticity.

Common specifications and production capacity

The specifications and production capacity of different models of production lines vary greatly. The following are reference parameters for mainstream models in the market. Some manufacturers can also customize equipment with larger width or higher production capacity:

|Model | Extruder specifications | Product width | Product thickness | Production capacity | Production line speed|

| ---- | ---- | ---- | ---- | ---- | ---- |

|XDC - 1200|90|1200mm|0.02 - 1mm|200kg/h|30m/min|

|XDC - 2200|120|2200mm|0.02 - 1mm|350kg/h|30m/min|

|XDC - 2800|65 + 120|2800mm|0.02 - 1mm|400kg/h|30m/min|

|1200/2400/3600 | Multi specification adaptation | 1000-3400mm | 0.02-3mm | Maximum 600kg/h | 5-30m/min|

Core application scenarios

In the medical field, we produce films that meet medical grade standards, which are used for packaging infusion tubes, inner layers of surgical gowns, waterproof and breathable layers of medical dressings, etc. They must be non-toxic, non allergenic, and able to withstand high temperature steam or ethylene oxide sterilization.

In the field of shoe materials and clothing, high elasticity TPU cast film can be used for the composite layer of sports shoe uppers and the elastic splicing parts of yoga clothes; Waterproof and breathable film can be compounded with fabrics to make outdoor clothing such as assault jackets.

In the field of electronics and daily necessities, ultra-thin TPU cast film is used as a key film for mobile phones and remote controls, with a soft touch and wear-resistant insulation; At the same time, it can produce inflatable beds, drinking bags, liquid filled insoles and other daily necessities, extending the product's service life with its good air tightness and bending resistance.

Packaging field: Transparent TPU cast film is used for packaging high-end food and precision electronic components. It has the characteristics of oil resistance, scratch resistance, moisture resistance, etc., which can extend the shelf life of products and protect them from damage.