PETG skin film production lines often use extrusion co extrusion technology, combined with specialized modified formulas and precision molding equipment, to produce thin films with delicate touch, stain resistance, and yellowing resistance, which are widely used in furniture panels, bathroom decoration, home appliance shells, and other fields. The following provides a detailed explanation of equipment composition, process key points, core parameters, and application scenarios:

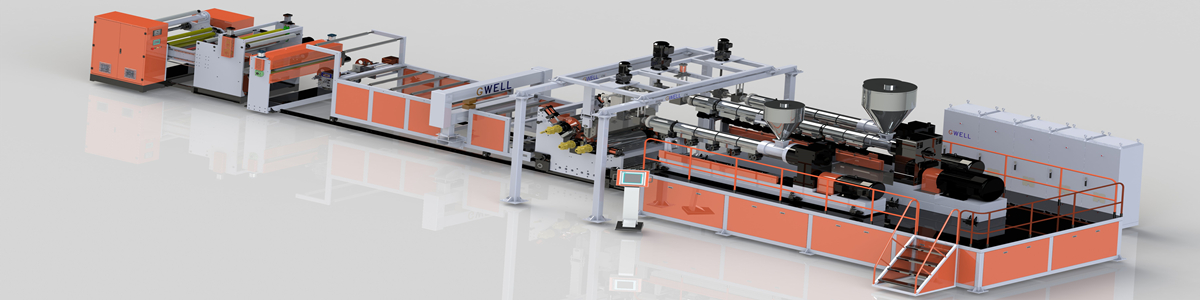

Core equipment composition

Extrusion system: The mainstream is a single screw extruder or a combination of twin-screw and single screw extruders for co extrusion. Single screw models are preferred for producing high gloss skin sensitive films, while twin-screw models are recommended for producing colored skin sensitive films to control costs. The screw is made of 38rMOA1A nitride steel, with surface treated by alloy spraying, and the length to diameter ratio is adapted to the melting characteristics of PETG. Some high-end models are equipped with melt metering pumps, which can stabilize the melt conveying pressure and ensure uniform extrusion volume. Paired with a hydraulic screen changer and precision filter, it can filter out impurities in raw materials and avoid defects such as black spots and crystal dots on the membrane surface.

Forming and cooling system: including precision distributor and hanger type die, capable of achieving AB, ABA and other layered structures, with digital display of layer ratios, suitable for the needs of skin sensitive film composite layers. The cooling process adopts a dedicated alloy steel thin-walled roller group, commonly used in horizontal three roll laminating machines. The rollers are independently driven, and the linear speed is synchronously closed-loop controlled with the extruder speed, which can quickly cool down and shape the film while ensuring the flatness of the film surface. Some inclined horizontal pressing structures are also convenient for later operation and maintenance.

Post processing and winding system: equipped with a corona machine, it can treat specific surfaces of the film layer to improve subsequent adhesion. The corona treatment power is usually 9-15kV, and the processing rate is 12-20m/s. Simultaneously equipped with an online thickness gauge, real-time monitoring of thickness and feedback adjustment; Most rewinding machines are designed with dual stations and equipped with waste edge recycling devices. The tension is controlled by a servo system to avoid wrinkles and bubbles during rewinding. Some production lines can also be equipped with cutting robots to achieve automated cutting.

Auxiliary control system: High end models often use exhaust units that do not require crystallization drying. The core vacuum system has been upgraded to have a higher vacuum degree, eliminating the need for additional crystallization drying treatment of PETG raw materials and reducing energy consumption. The electrical control adopts PLC system, which can achieve precise control of temperature, speed and other parameters. Some equipment supports remote operation and maintenance, simplifying labor costs.

Key process points

Raw material preparation: The basic raw material is mainly composed of 70-80 parts PETG, combined with 20-30 parts PBT to enhance heat resistance and wear resistance. At the same time, 0.05-0.45 parts toner is added to ensure skin feel. Functional additives such as modified antibacterial agents and flame retardants can also be added as needed. If modified additives are involved, a 30-50% concentration silane coupling agent solution should be used for pretreatment, followed by ultrasonic oscillation and centrifugal separation for later use.

Temperature control: The melting temperature of the barrel should be controlled at 180-250 ℃, and the temperature of the hot pressing and composite process should be precisely controlled at 180-200 ℃. The pressure should be 0.5-0.8kg to avoid excessive temperature causing degradation of raw materials and a decrease in skin feel. Low temperature can cause insufficient plasticization and weak interlayer bonding. The temperature of the cooling roller needs to match the molding rhythm to ensure that the film material is not easily deformed after shaping.

Composite molding: For PETG skin sensitive films with multi-layer structures, it is necessary to first prepare the skin sensitive surface layer and the functional bottom layer separately, then align the bonding surface of the skin sensitive film layer with other functional layers, remove bubbles, and perform hot pressing bonding. Some processes will undergo tempering treatment after forming to further enhance the toughness and dimensional stability of the film material.

Core specifications and production capacity

There are significant differences in the parameters of different manufacturers' models. The following are mainstream reference data in the market and support customized adjustments:

|Model related configuration | Width | Capacity | Key supplementary parameters|

| ---- | ---- | ---- | ---- |

|Jinweier GWS series | Suitable for multiple specifications such as board width 1350mm | Up to 1000KG/H | Motor power 600kw, compatible with PETG raw materials|

|Intelligent co extrusion production line | ≥ 2.1 meters | Annual design capacity of a single line can reach 12000 tons | Line speed above 35m/min, thickness control accuracy within ± 3 μ m|

|Small and medium-sized co extrusion machine | Common width for home decoration | Customized small and medium-sized production capacity according to demand | Suitable for small and medium-sized batch production, with relatively low equipment investment and a comprehensive gross profit margin of 28% -35%|

Typical application scenarios

The skin sensitive film produced by this production line is mainly used in the field of furniture decoration, such as customized wardrobe door panels, cabinet panels, and bathroom cabinet surface films, due to its environmental friendliness, strong weather resistance, and comfortable touch; It can also be used for decorating the exterior of household appliances, such as refrigerators and washing machines; It is also suitable for the transportation industry, used as decorative panels for train carriages and passenger car interiors, and has a small application in scenarios such as medical cleaning panels that require environmental protection and surface texture.