EVOH high barrier packaging sheet machine is a specialized equipment that relies on multi-layer co extrusion technology to produce sheets with excellent gas barrier properties. The produced sheets are mostly multi-layer structures such as PP/AD/EVOH/AD/PP, and are widely used in high barrier packaging in food, chemical, electronic and other fields. The following will explain the equipment composition, process key points, core parameters, and application scenarios:

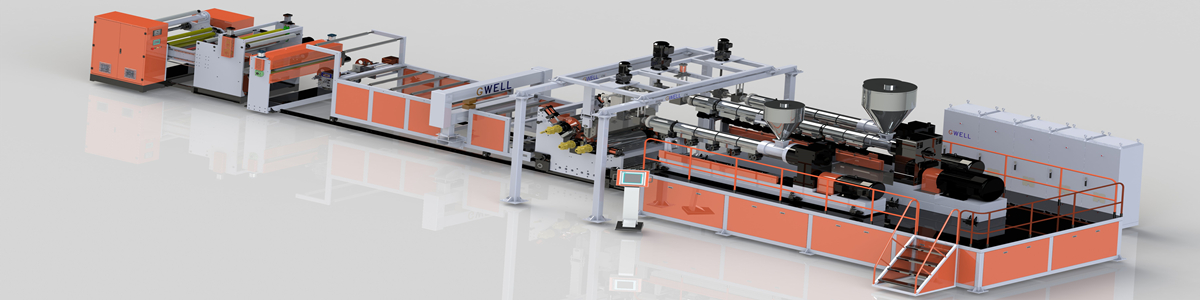

Core equipment composition

Extrusion system: The mainstream is the combination of multiple single screw extruders, suitable for the production of 3-9 layers of sheets. For example, the WJPG120/105/75/65/65-1200 model from Dacheng Environmental Protection uses 5 single screw extruders, corresponding to different raw materials such as PP, edge PP, EVOH, and adhesive AD. The screw specifications are matched according to the characteristics of the raw materials, such as 120 screws suitable for secondary PP materials, and 65 screws suitable for EVOH and AD materials. The equipment is also equipped with a melt metering pump and a hydraulic screen changer. The former stabilizes the conveying pressure to ensure uniform extrusion, while the latter filters impurities to avoid membrane surface defects.

Forming and shaping system: The core is a precision distributor and co extrusion die head. The distributor is equipped with adjustable blades, which can accurately control the thickness ratio of each layer. For example, the AD material is evenly distributed on both sides of the EVOH layer to achieve a multi-layer composite structure. Vertical three roll calendering machines or five roll laminating machines are commonly used in the shaping process. The rollers are equipped with constant temperature devices, which control the temperature through water circulation. This not only allows the sheet to quickly cool down and shape, but also ensures the flatness of the film surface.

Post processing and winding system: equipped with an online thickness gauge, real-time display and feedback of sheet thickness, convenient for timely adjustment; The trimming device is used to process excess edges, and when combined with a waste edge recycling or crushing device, PP waste edges can be recycled and sent back to the extruder for reuse. Double position winding machines are commonly used for winding, with variable frequency drives for constant tension control. Some models can achieve a maximum winding diameter of up to 1500mm, avoiding problems such as wrinkles and looseness during winding.

Electrical control system: The entire line adopts PLC control and human-machine interface operation, supporting digital adjustment of parameters such as variable frequency speed regulation. Some high-end models also incorporate intelligent design, which can achieve functions such as equipment operation status monitoring and fault warning, simplify operation processes, and improve production stability.

Key process points

Raw material adaptation and pretreatment: EVOH has poor compatibility with PP and must be compounded with AD adhesive to match the melt viscosity of AD and the two raw materials. At the same time, the moisture absorption of EVOH will affect its barrier properties, and the raw materials need to be dried to avoid bubbles and pinholes in the formed sheet. In addition, recycled PP waste can be integrated into the middle layer to form a seven layer structure that balances cost and performance.

Accurate temperature control: Different raw materials have different melting temperatures, and the temperature of each extruder needs to be controlled in different zones. For example, the extruder temperature corresponding to PP raw materials should be adapted to their melting characteristics. The EVOH extrusion temperature should avoid excessive degradation of the material, and the die temperature should be coordinated as a whole to ensure smooth fusion of multiple layers of melt and prevent problems such as delamination and weak bonding.

Inter layer structure control: Adjust the material flow rate of each layer through a distributor to control the thickness error of EVOH layer within ± 0.015mm. If adjusting the asymmetric structure, only the outer regulator can be operated to avoid insufficient resin in the inner bonding layer and prevent tensile fracture or delamination during secondary molding.

Mainstream specifications and production capacity

|Model | Extruder combination | Layers | Width | Capacity | Thickness range|

| ---- | ---- | ---- | ---- | ---- | ---- |

|Hangzhou Kangfa PY1000 | Φ 45/100/Φ 65/Φ 45 | 4-7 floors | ≤ 850mm | 350KG/H | 0.2-2mm|

|Jinweier GWS65/105/65 | Single screw combination | 3-5 layers | 800-1500mm | 250-350KG/H | 0.2-2mm|

|Jinweier GWS75/120/75 | Single screw combination | 3-5 layers | 1200-1600mm | 350-450KG/H | 0.2-2mm|

|Dacheng Environmental Protection WJPG120/105/75/65/65-1200 | 5 single screws | Multi layers | 800mm | 800-1000KG/H | Suitable for high barrier sheet conventional thickness|

Typical application scenarios

The sheets produced by this equipment have strong oxygen and moisture resistance properties, and are mainly used for food hard packaging, such as vacuum formed packaging boxes and trays for dairy products, meat, canned goods, etc., which can extend the shelf life of food; It can also be used as a packaging container substrate for liquid foods such as juice and beer. In addition, in the fields of chemical products and electronic component packaging, it can prevent external gases and moisture from corroding products; In the medical field, it can also be used for packaging medical consumables that require barrier properties and environmental friendliness.