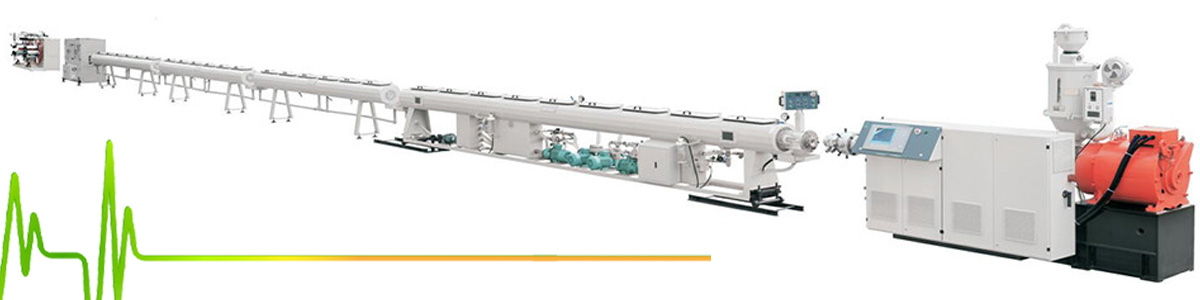

HDPE pipe

HDPE is a highly crystalline and non - polar thermoplastic resin.. The appearance of the original HDPE is milky white, and the thin section is translucent in a certain degree. PE has excellent resistance to most life and industrial chemicals. Some kinds of chemicals will produce chemical corrosion, such as corrosive oxidant (nitric acid), aromatic hydrocarbons (xylene) and halogenated hydrocarbons (carbon tetrachloride). The polymer is not moisture absorption and has good waterproof vapor, can be used for packaging purposes. HDPE has good electrical properties, especially the dielectric strength of the insulation, which is suitable for wire and cable. The high molecular weight levels have excellent impact resistance, at the normal temperature and even at the -40F low temperature.

HDPE pipe

PE; can be used to manufacture a wide, different processing method.. Such as sheet extrusion, film extrusion, tube or profile, injection molding and blow molding, rotational molding. Extrusion: for extrusion grade generally has less than 1 of the melt index and wide width to MWD. During the processing, the low MI can obtain the suitable melt strength. Wider MWD grade is more suitable for extrusion, because they have higher production speed and reduce the lower die pressure and melt fracture trend.

Use

PE has many uses, such as wires, cables, hoses, tubes and profiles. The scope of application for natural gas pipe from the small section of yellow tube to 48in diameter for thick wall pipe industry and city clarinet. Large diameter hollow wall tubes made of concrete made of rain water drain pipe and other water pipe substitutes grow rapidly.

Sheet and heat forming

Many large picnic cold storage tanks are made of PE, with toughness, light weight and durability.. Other products include sheet and thermoforming, fender tank lining, disk basin protective cover, transport boxes and cans. A large number of fast-growing sheet applications are film or pond bottom village, which is based on MDPE with toughness, chemical resistance and impermeable properties. Blow HDPE1/3 used in the United States for blow purposes.. These range from the bottle to the large refrigerator, car fuel tank and canister with bleach, oil, detergent, milk and distilled water.. Blow molding grade characteristic indices, such as melt strength, ES-CR and toughness, and for sheet and hot molding application level similar, so similar grade can be used. Injection & nbsp; & nbsp; & nbsp; & nbsp; blow molding is typically used to make smaller containers (less than 16oz), for drug packaging, shampoo and cosmetics. One advantage of this process is that the production of the bottle automatically goes to the corner, and does not need to be like the general blow molding process as the late dressing steps. Although there are some narrow MWD grade is used to improve the surface finish, generally used to wide width MWD grade. Injection molding.

HDPE pipe has countless applications, ranging from reusable thin walled drink cups to 5-gsl cans, consumption of domestic production of 1/5 HDPE. Injection molding grade general melt index 5 to 10, with toughness is low, liquidity grade and processing of higher mobility of the grade. Uses include the daily necessities and food thin wall packaging; there are toughness, durable food and paint cans; high resistance to environmental stress cracking applications such as small engine fuel tanks and 90-gal garbage cans.

The material used in this process is generally crushed into powder material, so that it is melted and flowing in the thermal cycle.. The use of two kinds of rotational PE: general and crosslinking type. General purpose MDPE/HDPE density range from 0.935 to 0.945g/CC, with a narrow MWD, so that the product has a high impact and minimum warping, its melt index range is generally 3-8. The higher MI grades are usually not applicable, because they do not have the impact of plastic products of hope and resistance to environmental stress cracking. The unique properties of high performance rotational application system using its chemical crosslinking grade. These grades in the first paragraph of the molding cycle, good fluidity and crosslinked to form a its excellent resistance to environment should stress cracking resistance, toughness. Wear resistance and climate resistance. The only available PE is the only suitable for large containers, ranging from 500-gal transport of chemicals to 20000-gal storage tanks.

Film

PE film processing generally use film processing or flat extrusion processing method. Most PE is used for thin films, general low-density PE (LDPE) or linear low density PE (LLDPE) are available. HDPE film grade is generally used to require superior tensile properties and excellent impermeable place. For example, the HDPE membrane is commonly used in commodity bags, grocery bags and food packaging. Product performance.

High density polyethylene was non-toxic, tasteless, and tasteless white particles, melting point of about 130, the relative density of 0.941~0.960. It has good heat resistance and cold resistance, good chemical stability, but also has a high rigidity and toughness, good mechanical strength. Dielectric properties, environmental stress cracking resistance is also better. The matters of attention 1, outdoor open laying, there are sunlight, the proposed shelter measures. 2, buried HDPE water supply pipeline, DN≤ 110 pipeline summer installation can be slightly serpentine laying, DN≥ 110 of the pipeline due to sufficient soil resistance, resistance to thermal stress, without reservation length; in winter, it shall not be necessary to reserve length. 3, HDPE pipeline installation, if the operation is too small (such as: pipe wells, ceiling internal construction, etc.), should use electric fuse connection mode. 4, hot melt spigot and socket joint, the heating temperature can not be too high, is too long, the temperature is best controlled at 210± 10 DEG C, otherwise it will cause too many parts in extrusion of lava, reduce watering diameter; socket pipe or pipe interface should be clean, or will cause the faucet off began to leak; at the same time, attention should be paid to control the angle and direction of the tube, avoid to cause rework. 5 and the butt connection, voltage between the 200~220V, if the voltage is too high will cause excessive heating plate temperature, the voltage is too low, the machine is not working properly; docking should keep on interface alignment, otherwise it will cause docking area insufficient, the weld strength is not enough, and curling asymmetric; the heating plate pipe connection.