Application range:

Mainly used in PP, PE film, bags and hard plastic recycling, PE / PP film, bags and hard plastic as raw material is granulated, with novel design, compact structure, rational layout, stable, and easy maintenance and debugging, low noise, low power consumption and other characteristics.

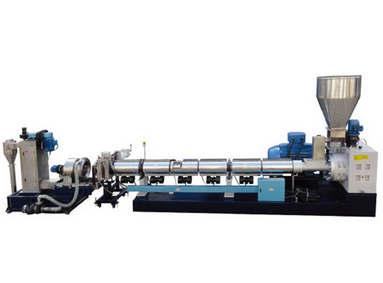

Device components:

Mainly by the forced feeding, extruding machine, hydraulic screen changer, water ring granulating die head, ring of water cut grain, chute + water tank, vertical dewatering machine, wind feeding storehouse, electrical control cabinet.

Note: we have aggregate water ring granulate production line, aggregate brace granulate production line, and forced feeding brace granulation production lines, different granulation methods have their unique advantages, you can according to the material selection of the most suitable machine.

Equipment specifications:

model

PPPE-65W

PPPE-90W

PPPE-100W

PPPE-120W

PPPE-150W

PPPE-160W

PPPE-180W

Screw diameter (mm)

Sixty-five

Ninety

One hundred

One hundred and twenty

One hundred and fifty

One hundred and sixty

One hundred and eighty

L/D

18-42

18-42

18-42

18-42

18-42

18-42

18-42

Screw speed (r/min)

10-150

10-150

10-150

10-150

10-150

10-150

10-150

Yield (kg/h)

80-130

180-200

200-280

250-300

300-400

400-500

500-650

Equipment advantage:

1 the production line of the introduction of Japanese technology, PE/PP material washing and crushing can be directly into the single screw extruder granulation.

2 the machine uses a large length diameter ratio screw, special exhaust equipment, can effectively remove water, to achieve high yield.

304 all of the material and water contact parts with high quality 3 stainless steel; ensure that the material does not have two pollution.

4 SIEMENS contactor, RKC temperature controller.

5 the particle, which is cut by the way of the water, is beautiful and uniform.