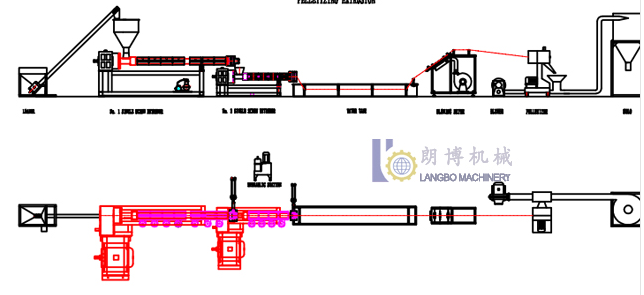

A.-PELLETIZING EXTRUSION EQUIPPED WITH SINGLE STAGE EXTRUDER

(STRING CUTTING / DIE FACE CUTTING UNDER WATER)

COMPONENTS AND FEATURES:

► The pelletizing extrusion of single stage extruder with string cutting consists of loader (built-in agglomerator/shredder drum)–extruder-die head-water tank-string pelletizer- collection silo.

► The pelletizing extrusion of single stage extruder with die-face cutting under water consists of loader (built-in agglomerator/shredder drum) –extruder-die-face pelletizer- centrifugal dryer-collection silo.

► High efficiency and performance.

► Less power consumption and operator attendance.

APPLICATIONS:

1) Applicable material: PP, PC, HDPE, LDPE, LLDPE, PET, EVA, PS, etc..

2) Materials shape: woven bag, printed films, agricultural film, raffia and rigid scraps.

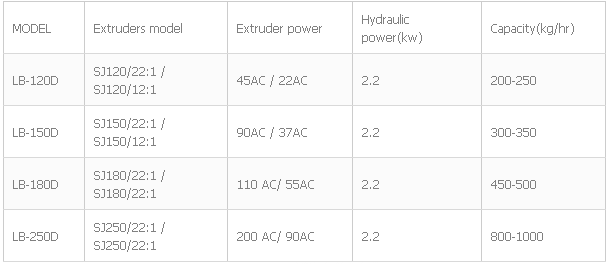

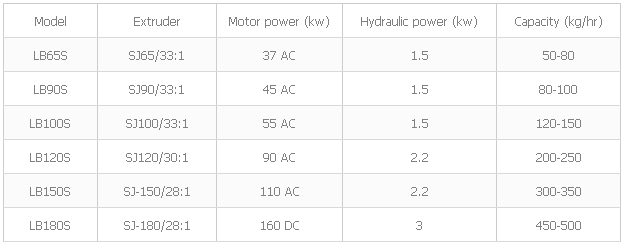

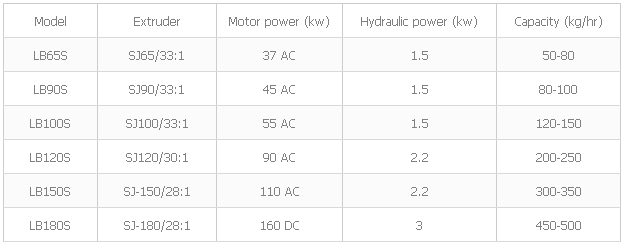

SPECIFICATIONS:

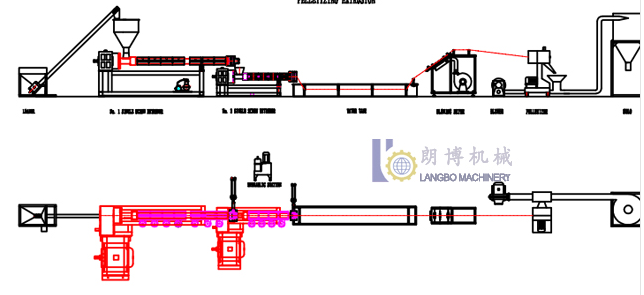

B.-PELLETIZING EXTRUSION EQUIPPED WITH DOUBLE STAGE EXTRUDERS

(STRING CUTTING / DIE FACE CUTTING UNDER WATER)

COMPONENTS AND FEATURES:

►The pelletizing extrusion of double stage extruders with string cutting consists of loader (built-in agglomerator/shredder drum)–extruder-die head-water tank-string pelletizer- collection silo.

►The pelletizing extrusion of double stage extruders with die-face cutting under water consists of loader (built-in agglomerator/shredder drum) –extruder-die-face pelletizer- centrifugal dryer-collection silo.

►High efficiency and performance.

►Less power consumption and operator attendance.

APPLICATIONS:

1) Applicable material: PP, PC, HDPE, LDPE, LLDPE, PET, EVA, PS, etc..

2) Materials shape: woven bag, printed films, agricultural film, raffia and rigid scraps.

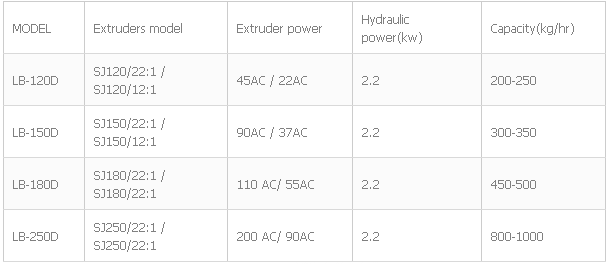

SPECIFICATIONS: