PXB200 series automatic hollow blow molding machine

PXB200 series fully automatic high speed blow molding machine to produce chemical packaging barrels, food, building coatings, drug packaging barrels, blow molding tool bags, automobile oil tank ,automobile hollow parts, flexible flow board, hollow seat, desktop board, large blow molding of toys, marina float, blow molding tray and large blow molding pipe , industrial, agricultural, military and other industries of blow molding parts, this machine is especially suitable for PE, PP raw materials Production capacity is 100 / hour (dry cycle) .the production of 220L drum (double-ring) is 15-18 p/h, the weight.is 10KG

PLASTIC PRODUCTS

TECHNICAL SPECIFICATION

| Specificaion |

| PXB200 |

| Material | PE.PP |

| Max container capacity | L | 230 |

| Output(dry Cycle) | PC/HR | 180 |

| Dimension(L×W×H) | M | 9.5×4.1×6.5 |

| Total weight | T | 36 |

| Clamping unit |

| Clamping force | KN | 800 |

| Platen opening stroke | MM | 880-1700 |

| Platen size | MM | 1200×1300 |

| Max mould size(W×H) | MM | 950×1600 |

| Mould thickmiss | MM | 900-960 |

| Power |

|

|

| Total power | KW | 266 |

| Max dirve | KW | 204 |

| Fan power for screw | KW | 1.5 |

| Oil pump power | KW | 45+22+5.5 |

| Air pressure | MPA | 1 |

| Air consumption | M3/MIN | 3 |

| Average energy consumption | KW | 160 |

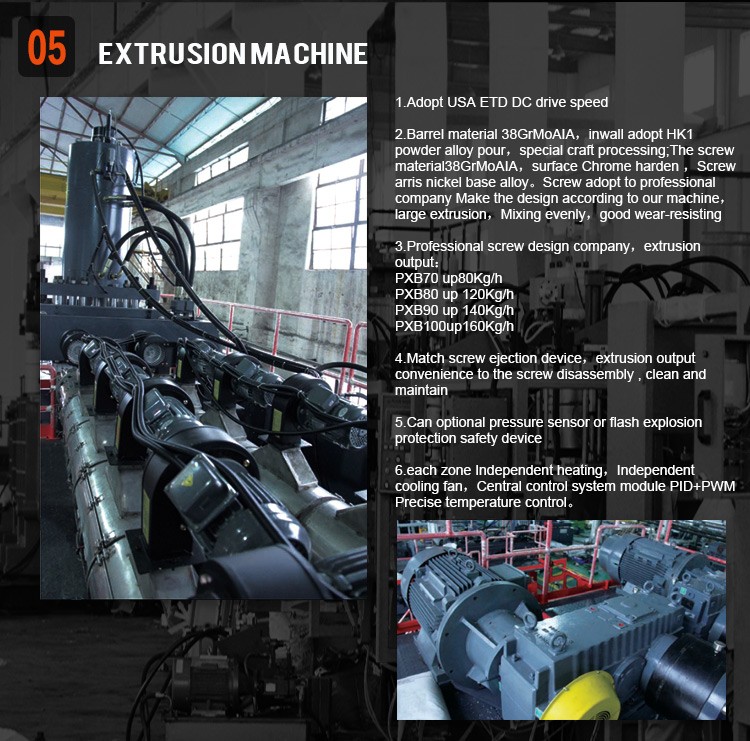

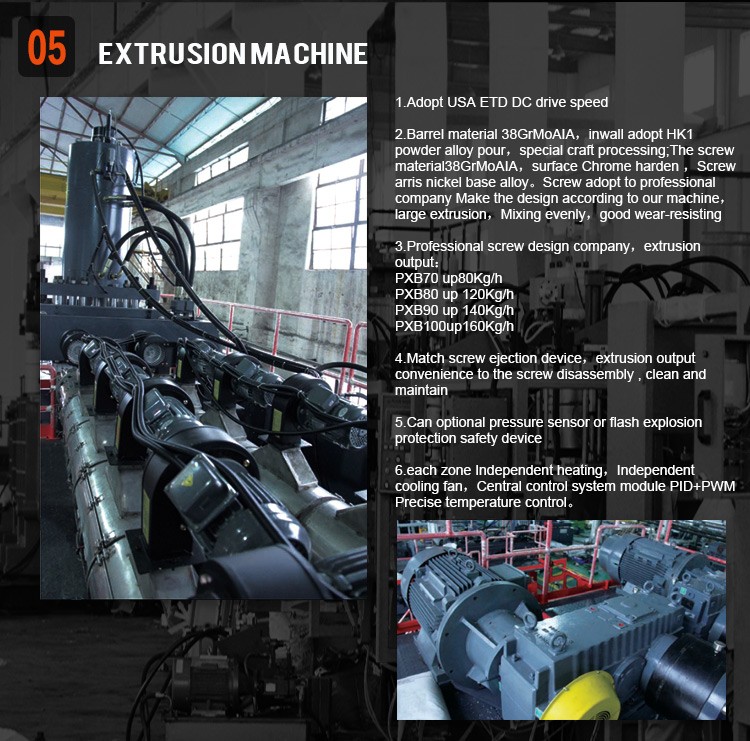

| Extruder unit |

|

|

| Screw diameter | MM | 120 |

| Screw L/D ratio | L/D | 30 |

| Output of HDPE | KG/H | 320 |

| Number of heating zone | ZONE | 6 |

| Extruder heating power | KW | 39 |

| Extruder driving power | KW | 132 |

| Die-head |

|

|

| Number of heating zone | ZONE | 6 |

| Power of die heating | KW | 38 |

| Max die pin diameter | MM | 500 |

| Accumulator capacity | MM | 22

|

| Features: |

| Clamping system:Single Station+High-precision guide+large arm cylinder axle |

| Extrusion System:Hard gear surface decelerator+Japan inverter |

| Die system:Center –incoming extrusion die with special steel |

| Hydraulic system:Japan hydraulic valve seal and proportional control |

Control system:Japan PLC+Imported+PLC automatic temperature control model +Imported electrionic parts |

| Application: |

| Dairy |

| Food/ Beverage |

| Cosmetic/Personal care |

| Lub-oil containers |

| Household chemical |

Industrial

|

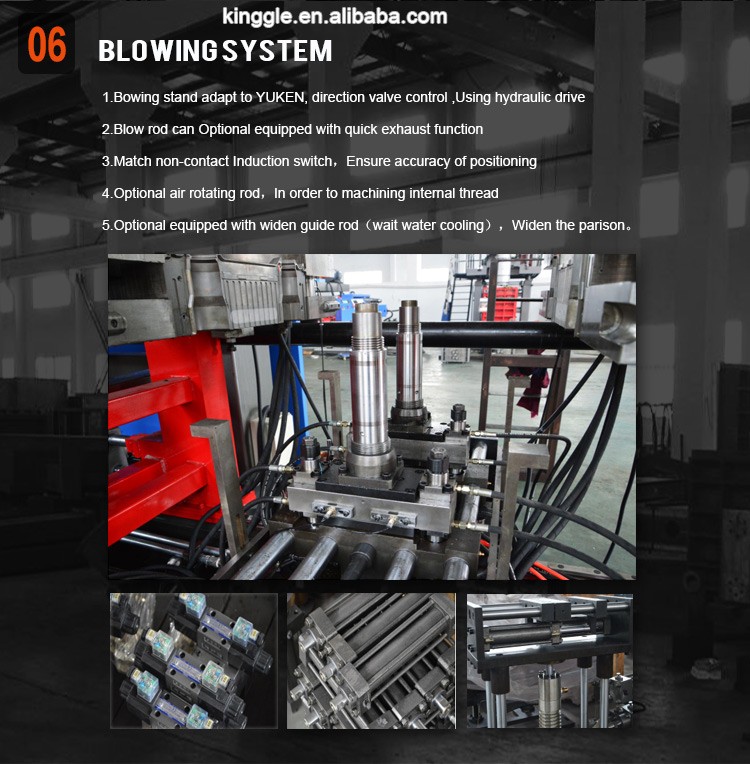

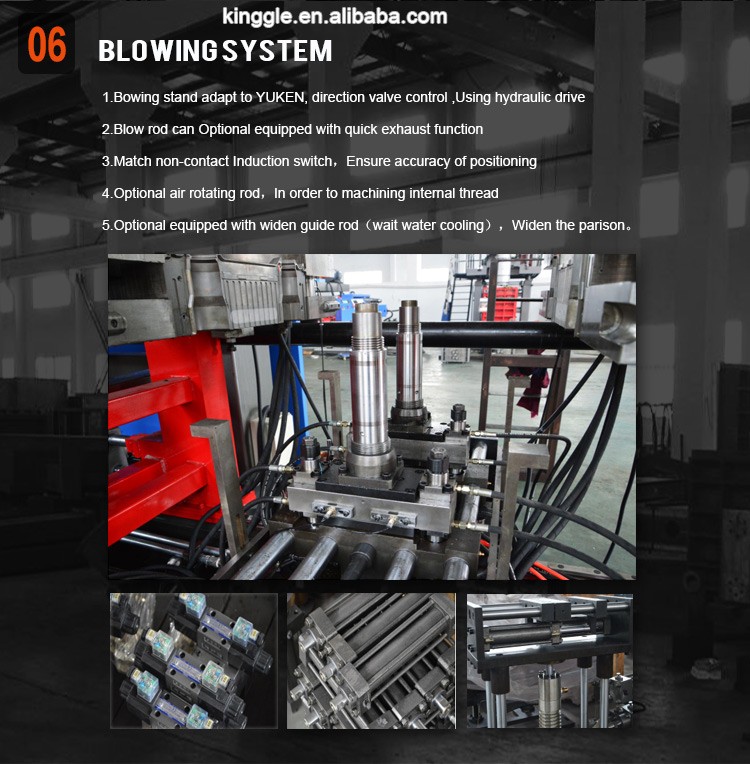

PXBS Series main configuration

Company Information

ABOUT US

OUR TEAM

PACKAGING & SHIPPING

OUR CERTIFICATION

FAQ

[1] Q: Are you a factory or trading company?

A: We are a factory.

[2] Q: Where is your factory located?

A: Our factory,near Shanghai & Ningbo port, Ningbo ,zhejiang .

[3] Q: How about quality control in your factory?

A: “ Quality is the key point, do what customers need”

Kinggle machinery factory focuses on quality,quality control from beginning to the end. Every piece of goods

is tested strictly before packing and delivery.

[4] Q: How about guarantee ?

A: One year guarantee.

[5] Q: Do you provide blow molding machine ,mold and auxiliaries equipments?

A: Yes , we can provide full blow molding machine line ,before and after sales service

[6] Q: What is the language of the PLC and touch panel?

A: Don’t worry, we will translate the language in English,or other languages to make sure you will have an easy operation .

[7] Q: Can you offer big size blow molding machine? Can you make multilayers and multi-colors?

A: Yes,we can offer you up to 2000L blow molding machine,our factory have patent for the multilayers and multi-colors!

Our Services

The warranty period for Kinggle machine is one year with a life long maintenance.

If the user requires special quality guarantee, other stipulated warranty period may be made after mutual agreement.

1. Reply the email and take action in 24 hours; |

2. 100% Quality inspection before the shipment; |

3. Can trainning clients operator for free in seller`s factory |

4. Engineer overseas is avilable |

5. Blowing mould and injection mould made orginal |

6. Auxiliary machines for complate line. |

7.Custimized design as requirements. |

8.Introduce our engineer come to customer’s factory working! |

Sam Zhang

NINGBO KINGGLE MACHINERY CO.,LTD

TEL:0086 574 87103665

Mail:service@kinggle.cc

Skype:sam12130

Whatsapp/Viber:0086 15868155663