JC-BM series brake pads dedicated machine series

I. Features:

BM brake pads dedicated machine has a simple structure, system stability, high pressure, high efficiency notable features.

Second, use:

BM molding machine, also known as brake pads brake pads dedicated machine, the machine

Mainly used in all kinds of automobile brake pads thermoforming. Also be used for other flat vulcanizing rubber molded products, such as: rubber / silicone products, seals, O-rings, oil seals, rubber shock pad, keyboard, medical rubber parts, electrical insulation parts and other kinds of rubber products and bakelite products , crafts and other models pressing. This equipment is mainly suitable for all kinds of automobile motorcycle brake pads.

Third, the structural characteristics:

A Rapid clamping, high production efficiency; slow locking, mold protection.

(2) Imported seals, reliable, long life.

3 selection of the inlet valve, advanced oil, save energy.

4 using neutron cylinder devices, products to prevent exhaust ran materials; product ejection up automatically when the neutron separation products, and convenient.

5 Electrical system adopts PLC programmable controller and touch screen interface combinations, high degree of automation, manual and automatic switch freely; simple to understand;

6 equipped with safety light curtain, the operation safer.

Fourth, the action process:

Initial state paved the steel mold reset fed into a mold cavity program starts fast mold clamps slowly, exhaust pressure, curing mold in place, neutron rise, mold automatically removed from the product.

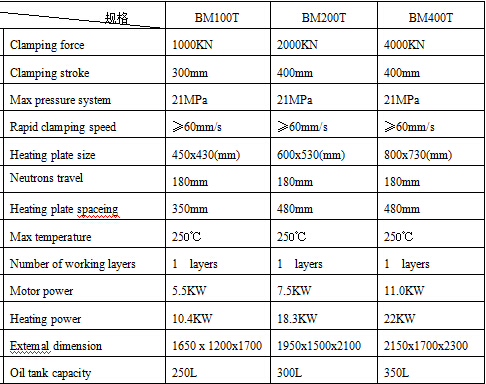

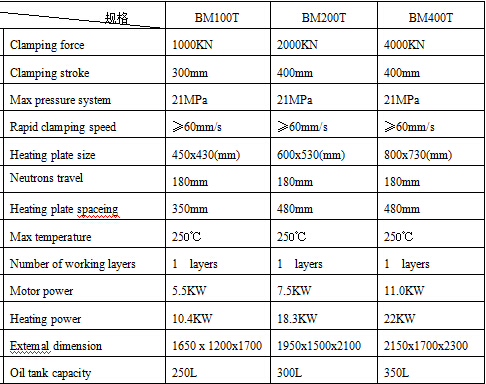

V. Technical parameters:

JC-BM series brake pads dedicated machine series

I. Features:

BM brake pads dedicated machine has a simple structure, system stability, high pressure, high efficiency notable features.

Second, use:

BM molding machine, also known as brake pads brake pads dedicated machine, the machine

Mainly used in all kinds of automobile brake pads thermoforming. Also be used for other flat vulcanizing rubber molded products, such as: rubber / silicone products, seals, O-rings, oil seals, rubber shock pad, keyboard, medical rubber parts, electrical insulation parts and other kinds of rubber products and bakelite products , crafts and other models pressing. This equipment is mainly suitable for all kinds of automobile motorcycle brake pads.

Third, the structural characteristics:

A Rapid clamping, high production efficiency; slow locking, mold protection.

(2) Imported seals, reliable, long life.

3 selection of the inlet valve, advanced oil, save energy.

4 using neutron cylinder devices, products to prevent exhaust ran materials; product ejection up automatically when the neutron separation products, and convenient.

5 Electrical system adopts PLC programmable controller and touch screen interface combinations, high degree of automation, manual and automatic switch freely; simple to understand;

6 equipped with safety light curtain, the operation safer.

Fourth, the action process:

Initial state paved the steel mold reset fed into a mold cavity program starts fast mold clamps slowly, exhaust pressure, curing mold in place, neutron rise, mold automatically removed from the product.

V. Technical parameters: