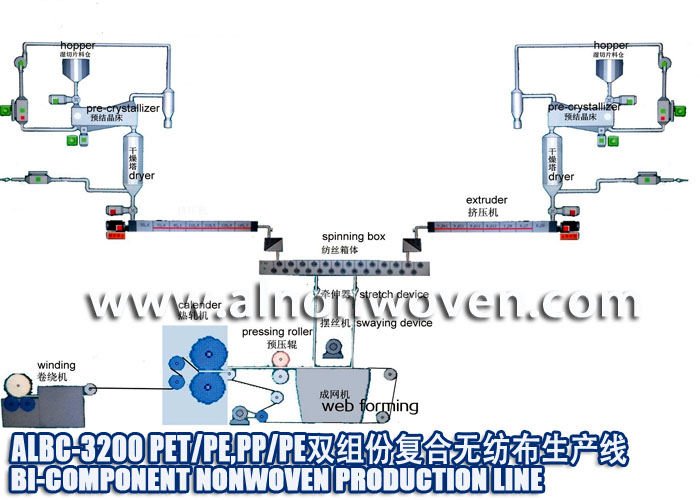

ALBC-3200 PET/PE, PP/PE Bi-component Nonwoven Production Line

PET/PE, PP/PE Bi-component Nonwoven Production Line is the new production in the nonwoven industry.PET/PE,PP/PE are dealed with by the method of spunbonded calender . And cooperated with scientific and rational design, which make not only our line running well but also nonwoven showing Soft feel, good compound, strength, waterproof performance, good adhesion etc. This kind of nonwoven can be used widly in disposable medical supplies, sanitary supplies, baby diapers, waterproof materials etc.

Characteristics of production line

1.The whole line is reasonable in structure and convenient in operation.

2.High degree of automation across the board.

3.Control components all adopt famous brand products, stable performance and reliable control.

4.Full line controled by PLC in touch screen control operation.

5.Main and auxiliary equipment layout can be designed according to user configuration conditions.

Technical Parameter

Model:ALBC-3200

Bi-component nonwoven width: 3.2m

Frbric GSM:16~160g/m²

Composite ratio(valume ratio):PP/PE=(55~65)/(45~35)

Composite style: Skin core (PP core, PE for skin)

Spinning speed: 1) mechanical speed: 2000~3000m/min; 2) process speed 1000~2000m/min Final roll door width: 3.2 meters

Anual output:(2000m/min, 2.5den): 3000t/a

The whole machine power: 1) the whole machine installed power is less than or equal to 1580KW; b) the whole machine power consumption: less than 20kw/h.

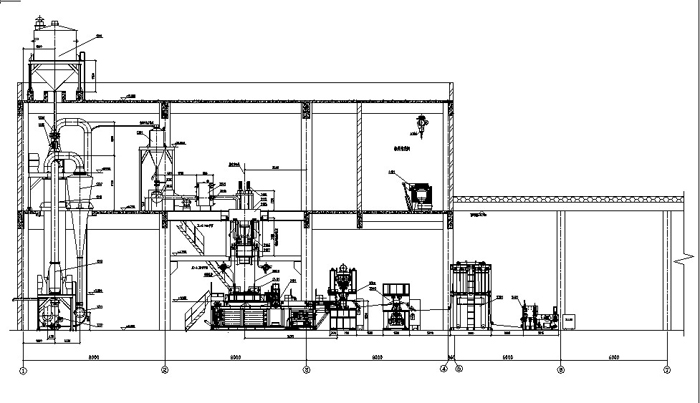

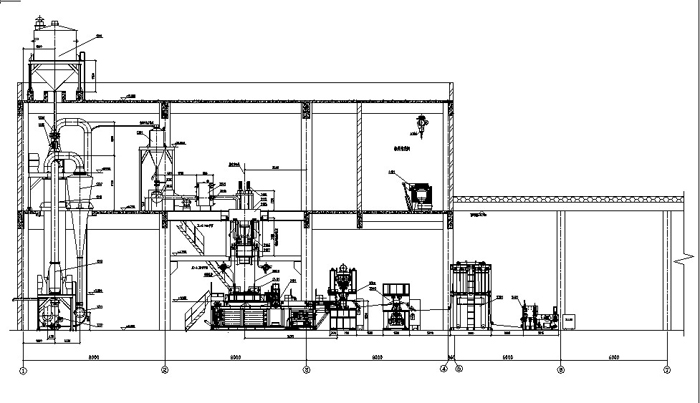

Machine Size (L*W*H):25Mx12Mx12M

Spinning part size ( L*W*H) :20M x 12Mx12M