Characteristics:

It can process all kind of plastics products with auxiliary machines concerned, such as film, pipe, stick, plate, thread ,ribbon, insulating layer of cable, hollow products and so on .It is also used in graining. The machine design is advanced, production capacity is high, plasticization is good, and energy consumption is low. The extruder adopts hard gear surface for transmission. It has advantages of low noise, smooth operation, large loading, long use-life and so on

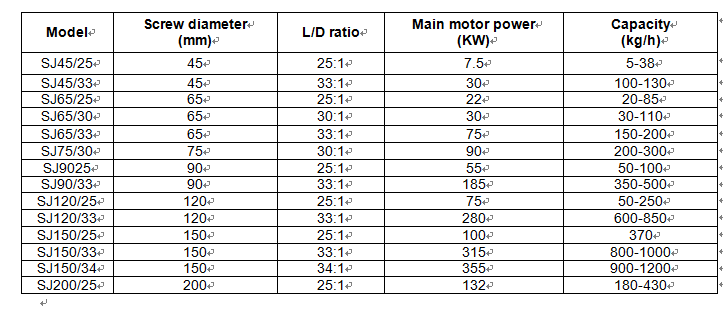

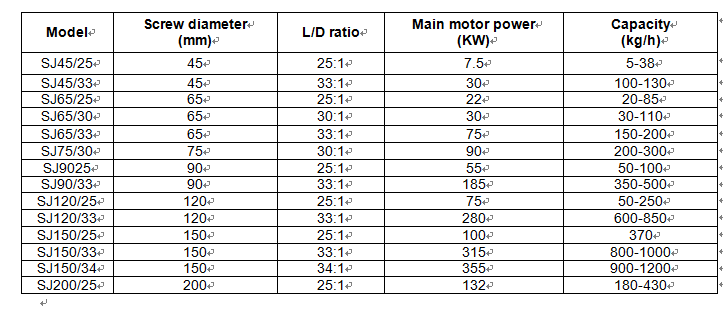

Main Technical Parameters

Features:

Ø Applications: Suitable for extruding all types of polyene materials

Ø Suitable screws: 45, 65, 75,90, 120, 150, 200

Ø Controller: Normal, PID or PLC (optional)

Ø Can be combined with various auxiliary machinery

Ø Length / diameter ratio can be changed (suitable between 25: 1 - 36: 1)

Ø Specially designed screw, high-torque decelerator and high power DC motor ensure good mixture of material and high output

Ø More flexible processing range; it can be used for recycling, pelletizing, pipe, profile, board/sheet/film extrusion.

Advantages:

l Lower specific energy consumption; energy saving could be up to 30% plus.

l Higher capacity: the capacity could be 50% more at the same diameter

l Higher efficiency in plastication.

l Better mixing effect: it is comparable with normal twin screw extruder

l More accuracy in extrusion processing control.