Advantages of technology

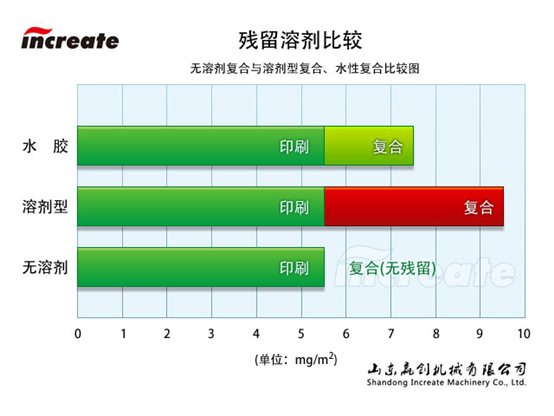

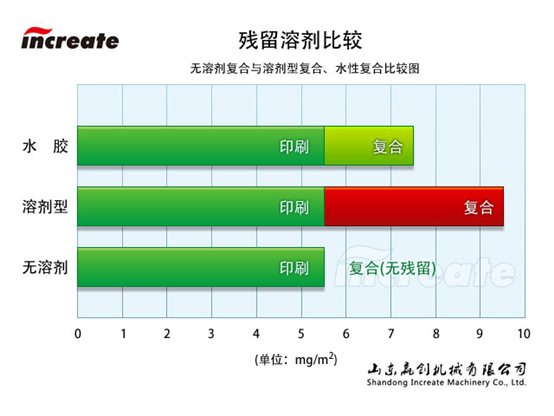

In compound material, no solvent residual, especially as to meet the requirements of modern health of food and pharmaceutical packaging.

In the production process there’s no volatile solvent emissions, no pollution to the atmospheric environment, excellent production environment.

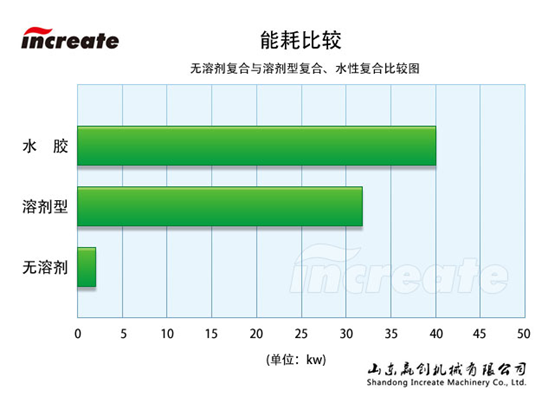

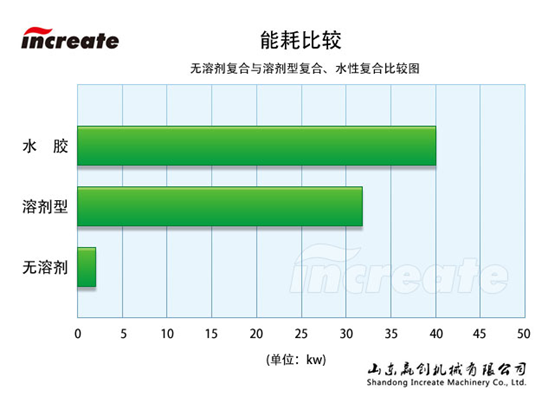

Because they do not use the conventional drying system, therefore can significantly reduce energy consumption, low production cost.

Coating glue and total cost has certain decrease than existing technology.

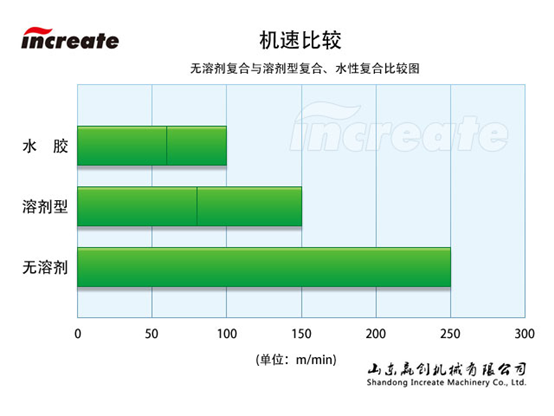

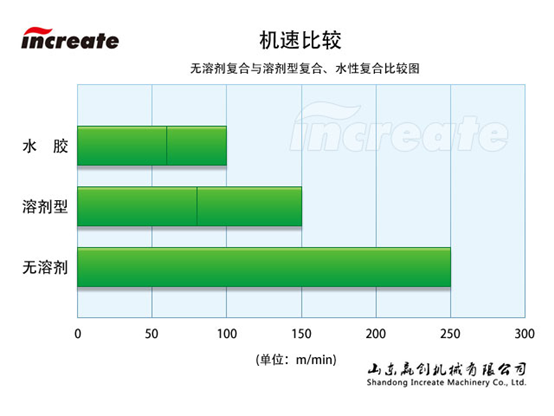

Machine speed fast, small footprint, no fire and explosion risk.

Solvent-free compound compared with solvent-based compound, water-based compound

| Item | Solvent-based compound | Water-based compound | Solvent-free compound |

|---|

| Offer glue | Artificial mixing | Sometimes artificial mixing | Automatic |

| Coating | Anilox roll | Anilox roll | Smooth roll |

| Coating weight | Not adjustment online | Not adjustment online | Adjustment online |

| Drying | Have drying tunnel | Have drying tunnel/high temperature | No drying tunnel |

| Speed | Intermediate speed | Intermediate and low speed | High speed |

| Winding /Unwinding | Artificial /semi-automatic | Artificial /semi-automatic | Artificial /semi-automatic |

| Cleaning | Anilox roll/glue tray | Anilox roll/glue tray | Smooth roll |

| Degree of automation | Intermediate | Intermediate | High |

Machine Speed compare

Energy Consumption compare

Residual Solvents compare

The range of composite material and the requirement of surface tension

Solvent-free plastic- plastic laminating machine can be composite substrates are mainly

BOPP,PET,Nylon,CPP,PE,VMPET,VMCPP,PVC,paper,etc,base material is generally applied thickness in 7um-120um (According to the equipment).

The surface tension of the BOPP, PE, CPP, VMCPP general than 38 dyne;

PET film surface tension must be more than 48 dyne;

BOPA(NY)、PVDC and so on must up to 52 dyne.

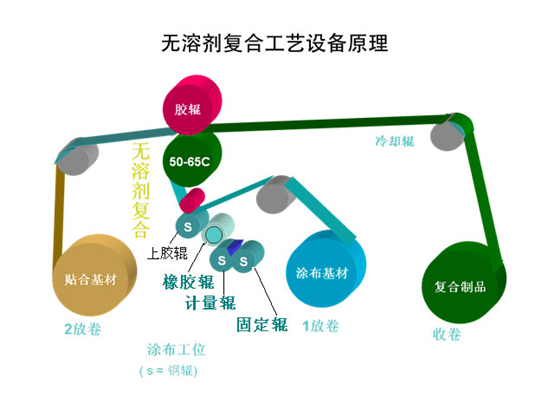

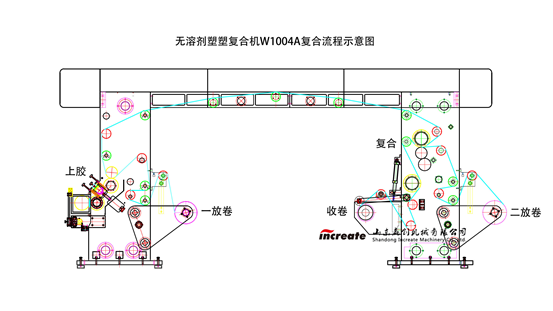

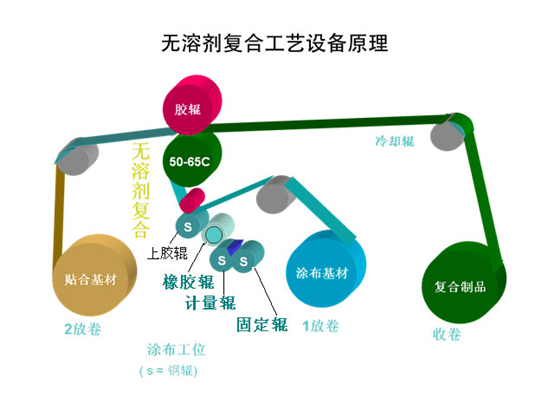

Solvent-free plastic- plastic laminating machine equipment principle

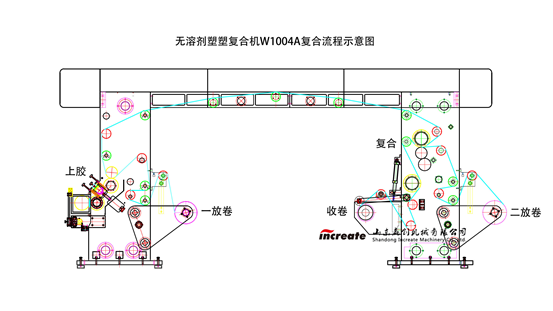

Solvent-free plastic- plastic laminating machine compound process diagram

Solvent-free plastic- plastic laminating machine specification

| Item | Parameters |

|---|

| Compound speed | 10-400m/min(According to base material, glue features) |

| Compound width | 600mm-1050mm |

| Unwinding diameter(Max) | Φ800 |

| Winding diameter(Max) | Φ1000 |

| Base width(Max) | 1050mm |

| Paper tube length(Max) | 1050mm |

| Paper tube standard | Inner diameter Φ76mm×Outer diameterΦ92mm |

| Winding paper core | 3 Inches |

| Guide roller length | 1100mm |

| Coating weight | 0.7~2.7g/m2 |

| Composite pressure | 700kg/Full width |

| Composite roll temperature | 5~60℃ |

| Preheat roll temperature | 5~50℃ |

| Total Power | About 45KW |

| Power supply | Three-phase five-wire 380V 50Hz |

| Air pressure | 0.6Mpa |

| Equipment weight | About 6000KG |

| Equipment size | 6000mm×3000mm×2500mm(L×W×H) |