Features:

1. Suitable for all kinds of thermoplastic raw materials, foaming or non-foaming, such as PVC and TPR.

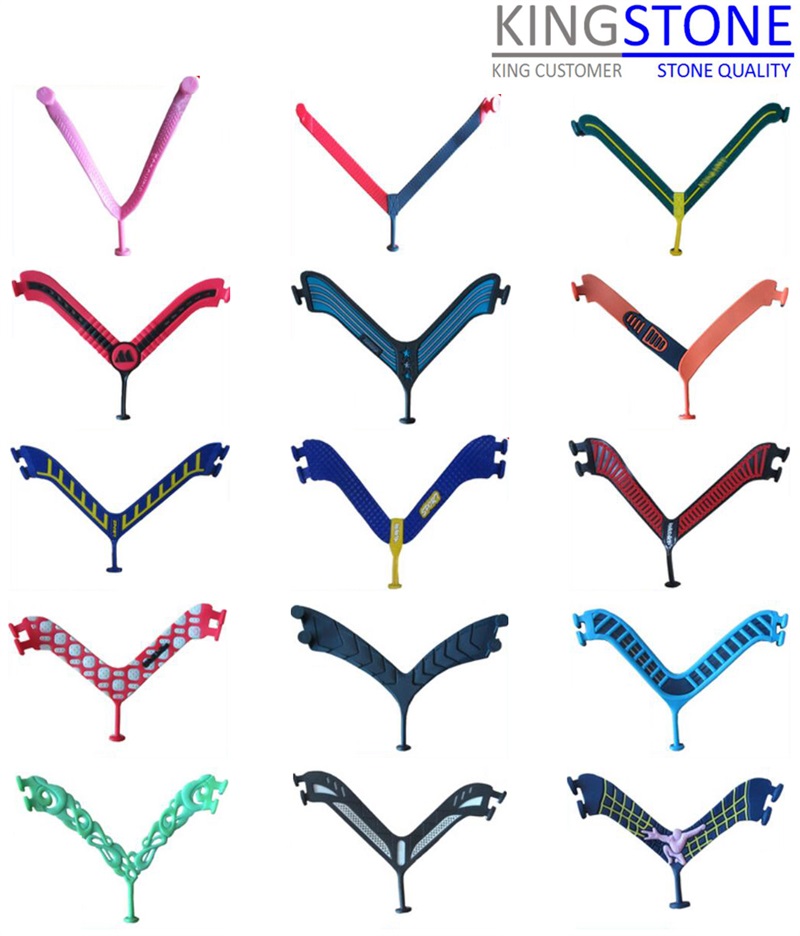

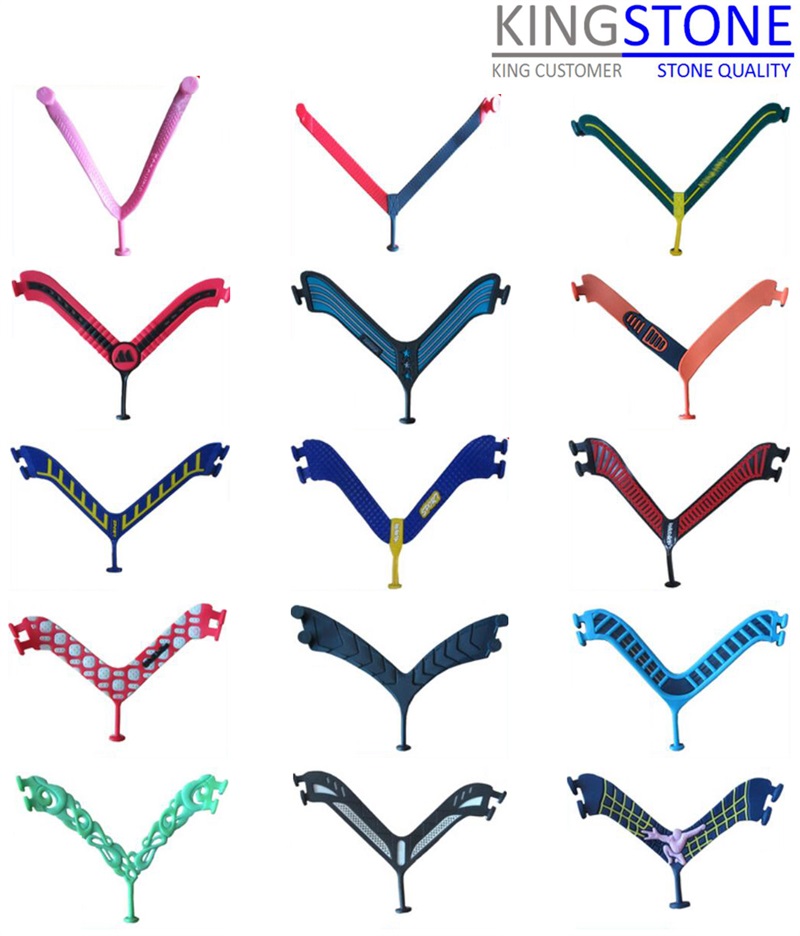

2. Specialized in producing various kinds of one/two/three color slipper uppers

3. Conformed to human engineering in design, it features operational compatibility.

4. The well-interconnected oil circuit by electric control can reduce waiting time, quicken production rate, and promote productivity.

Specifications |

|

Machine model | JL-138-2C | JL-138-3C |

Mould-clamping Unit |

Work station |

| 6 | 6 |

Clamping force | TON | 80 | 80 |

Opening stroke | MM | 210 | 210 |

Mould dimension | MM | 420x320 | 420x320 |

Height of injection nozzle | MM | 280 | 280 |

Injection Unit |

Injector | SET | 2 | 3 |

Screw diameter | MM | 50,40 | 50,40,40 |

Screw L/D ratio | L/D | 20 | 20 |

Max.injection volume | cm3 | 350,200 | 350,200,200 |

Injection speed | Cm/s | 500 | 500 |

Screw rotation speed | R.P.M | 10 | 10 |

Electricity Consumption |

Heating power of injector | KW | 8/4 | 8/4/4 |

Hydraulic unit motor | KW | 11/7.5 | 11/7.5 |

Total electric consumption | KW | 30.5 | 34.5 |

Temperature control | Section | 3 | 3 |

Dimension and Weight |

Machine dimension | (L*W*H)MM | 3500*2500*2900 | 3500*2500*2900 |

Machine weight | KGS | 6000 | 6200 |

*Note:Above data only for reference. |