Advantage of our machine:

1. The rise and fall of the calibration unit, adopts ELECTRIC LIFTING, easier operation.

2. Equipped with INDEPENDENT LIFT to remove and reinstall the mould, replace the heavy gantry, and greatly saves space, safer and more beautiful

3. Equipped with AUTOMATIC DISMANTLE DEVICE, reduce the labor force.

4. The DIAGONAL of the board can be adjusted independently, very convenient

5. This machine can produce pvc products of different specifications only by changing mould

6. All the electrical parts in line are from famous brand supplier, Siemens, Omron &ABB brand, insure the machine can run smoothly. The machine also has the features of high automation, easy operation, etc.

7. The auxiliary units are able to use the PLC control, which is stable and reliable.

Features and advantages of PVC building template compared with traditional template:

1. Good water resistance. Even if it’s completely soaked in water long time, also won't deform because of damp, or decay and rust.

2, Incompatibility and not sticky with cement, demould easily after construction, also won't deform because of the adhesion of cement.

3. High construction efficiency, good quality. The building surface is smooth and flat, no need of second modification.

4. Save the working procedure, improve the efficiency of the construction. At the same time can also do the surface pretreatment of template in processing templates, get the wanted metope decorative pattern.

5. Light weight, convenient construction.

6. Long life, reused many times. Damaged plastic template can still be shattered, reprocessed into new template, save resources.

7. Good heat preservation, beneficial to shorten the construction period.

8. Can use any wood working tool on it.

Application of PVC building template:

Can be widely used in industry, agriculture, national defense, construction, household appliances and daily necessities and other fields, it can be used to make all kinds of products, such as: industrial tray, warehouse plate, platform floor, warehouse shelves, wooden fence, beach chair, floor, etc.

Operating specifications of PVC building template:

1. Applies to the high-level architecture level template, shear wall, vertical wall, dam, tunnel, bridge and templates, etc.

2. Cutting template: applicable to any saw blade, hand saw, electric saw, etc. Can be cut into any irregular geometric shapes, and there will not be any burrs.

Construction standard:

1. The timber close to the template needs to be laid vertically. Minimize plate seam, use adhesive tape, and keep smooth between board and board.

2. Top template: first spread the square timber across the scaffolding, spacing is 1.2 m, longitudinally pave the timber again, distance is not more than 300 mm. When the thickness of casting is more than 200 mm, the spacing should be turn down appropriately.

3. Wall template: longitudinally pave the timber after template, spacing is 250 mm - 300 mm. Then cross two square timbers to connect, leave a good wall screw position, make good brace, horizontally can use steel joist to connect to be combined modular wall die, and can directly lift, also remove single block template.

4. Beam template: cut out the template according to the size, leave wall screw position, use scaffolding to lock the beam, make brace.

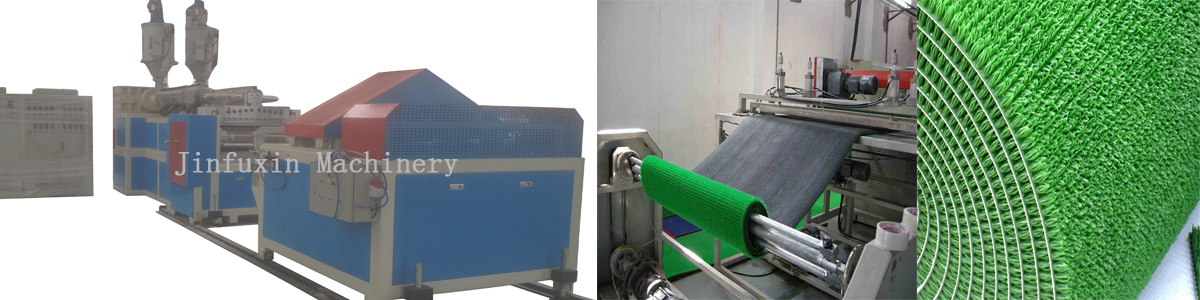

Components of the machine

The machine consists of conical twin screw extruder, T-die mould, calibration unit and haul-off parts, uses special designed screw structure, considering variously from technology to the formula, makes the produced building template no deformation in high temperature, no crack under low temperature.

Conical twin screw extruder

ABB inverter

Siemens contactor

Harden and helical gear. conjoined gearbox, thrust bearing is NSK (Japan)

Motor power: 75KW

Mould (T-Die)

New designed mould, can work for longer time, easy to operate.

Equipped with INDEPENDENT LIFT to remove and reinstall the mould, replace the heavy gantry, and greatly saves space, safer and more beautiful

Equipped with AUTOMATIC DISMANTLE DEVICE, reduce the labor force.

High quality alloy steel

Calibration unit

Calibration plate:1500mm×500mm 4 pairs

The rise and fall of the calibration unit, adopts ELECTRIC LIFTING, easier operation.

Cooling bracket:

The DIAGONAL can be adjusted independently, very convenient

Haul-off:

Cylinder clamping and loosening

Roller qty: 8 pairs

Cutting unit

Stacker

SWP700 Crusher

Crush the PVC WPC foam board offcut into scraps.

600 Grinder

Mill the PVC WPC foam scraps into powder

500/1000 Mixer

Mix the main materials with other additives