A:

Descriptions :

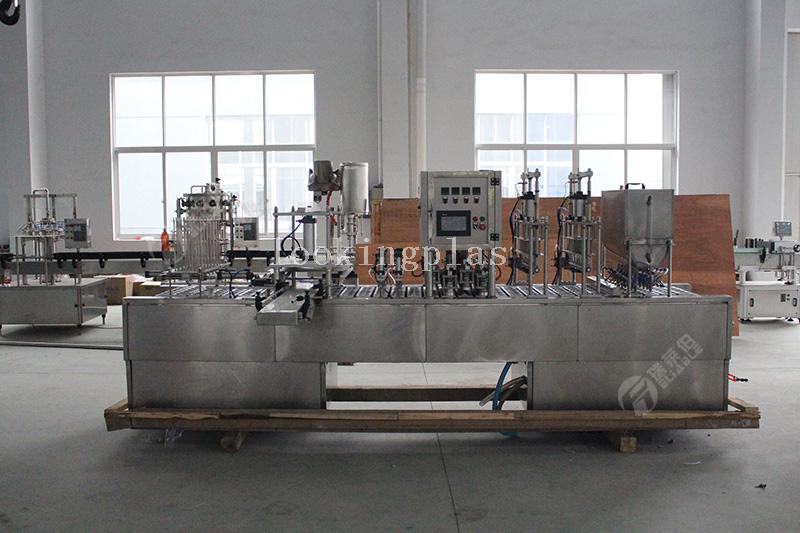

The machine is the automatic filling & sealing special equipment for all kinds of type plastic cups. It works automatically from loading cups automatically, filling regularly, setting cover by machine-handle, sealing for two times, carrying cups, pushing cups to transmission. It is suitable for yogurt, milk, salad, fruit-juice, beverage and other drinks and foods.

Both the machine and components are well known products that have been imported from Germany, Japan and other advanced countries. As the whole machine is made of stainless steel, it is completely hygienic and meets the relevant sanitary standards. We can customize all specifications &types according to costumers' demands

B:

Functions:

1. Beautiful, clean, bright shape of machine.

2. Made of stainless steel (except for the parts which connect with the materials) and meets the sanitation standards for foodstuff.

3. Uses air pressure to drive.

4. Complete function.

5. The whole process is completely automatic from container supplying, filling, sealing, leftover materialcutting, pruduct being moved out to leftover material receiving.

6. Can fill, seal and cut several containers at the same time.

7. Improve the production efficiency.

8. Has photoelectric eyes.

9. Can automatically correct the film sealing position and ensure the sealing position is right

10. Fitting for filing and sealing all kinds of liqid and products like paste, such as jelly, milk, ice cream, mineral water, jam, etc.

Characteristics:

1. Advanced design, reasonable structure, reliable performance;

2. Fully automatic operation, adjustable production speed, easy operation, safety, increase productivity, reduce labor costs;

3. Photoelectric sensor track ensure accurate sealing;

4. Twice sealing, sealing pressure can be adjusted according to customer requirements as easy or difficult to tear, reflecting greater humanization design;

5. Seal firmly and smooth flawless;

6. Customize equipment according to the customer requirements and other accessibility features;

7. Configuration: this machine uses the channel steel, welded together, after 3 times anti-rust treatment