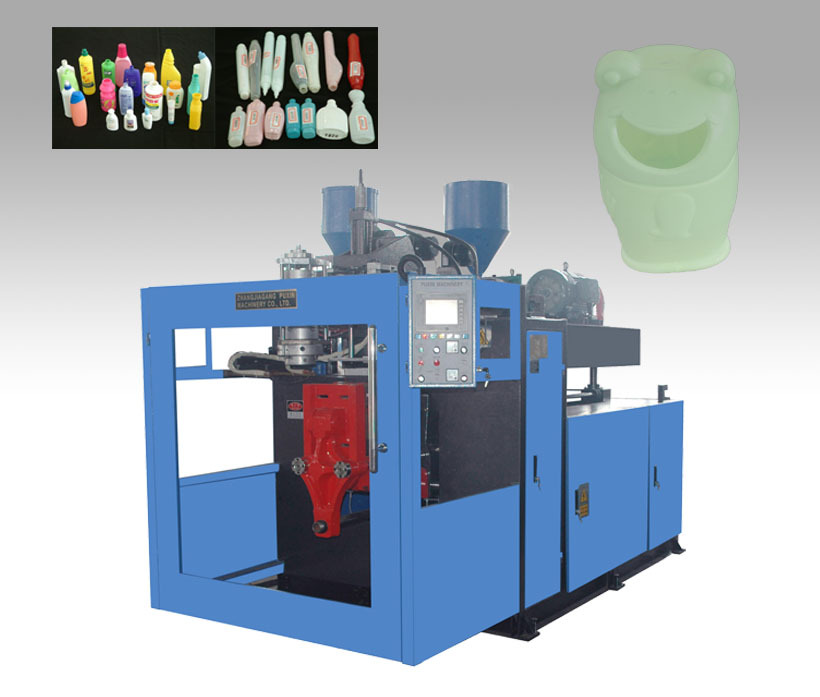

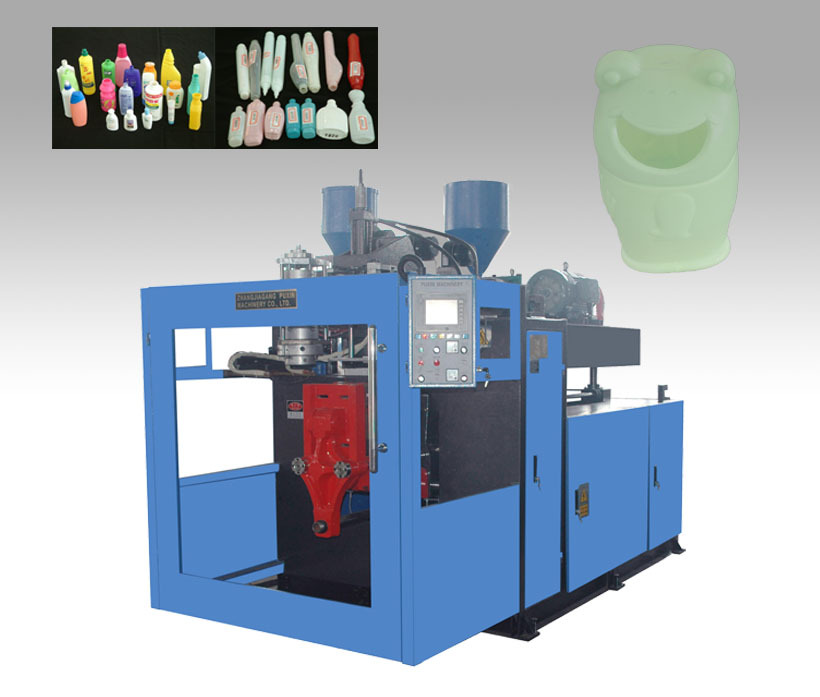

PXB70 series automatic hollow single station blow molding machine is suitable for many kind of bottles within 5L-12L,such as such as sauce boat ,shampoo bottle,pesticide bottle,transfusion bottle,ripple pipe,toy ,etc.

Die head: Special steel and centre feed extrusion die head;

Extruder unit: adopt automatic temperature control unit of import,the screw united by

frequency motor,hard tooth surface gear box to achieve stepless speed regulation;

Clampling device: Across the basement type double linear guide and move mould

strengthen rigidity. Template is three bar with center clamping system

Hydraulic system: whole system adopt imported components, proportional control flow,

Fast response, more stable, power consumption without loss;

Electric controlling system: it adopts Japan programmable controller, touch

screen,the characteristic of it has direct manipulation and large information on board.

TECHNICAL SPECIFICATION |

Specificaion |

| PXB70 | PXB90D |

Material | PE.PP.PVC.PA |

|

|

Max container capacity | L | 12 | 12 |

Output(dry Cycle) | PC/HR | 800 | 600×2 |

Dimension(L×W×H) | M | 3.8×2.1×2.8 | 4.2×3.4×2.8 |

Total weight | T | 5 | 8 |

Clamping unit |

Clamping force | KN | 95 | 95 |

Platen opening stroke | MM | 200-600 | 200-600 |

Platen size | MM | 550×420 | 550×420 |

Max mould size(W×H) | MM | 580×470 | 580×470 |

Mould thickmiss | MM | 210-330 | 210-330 |

Power |

Total power | KW | 64.1 | 78 |

Max dirve | KW | 37 | 52 |

Fan power for screw | KW | 0.4 | 0.4 |

Oil pump power | KW | 15 | 15 |

Air pressure | MPA | 1 | 1 |

Air consumption | M3/MIN | 0.9 | 0.9 |

Average energy consumption | KW | 23 | 38 |

Extruder unit |

Screw diameter | MM | 75 | 90 |

Screw L/D ratio | L/D | 24 | 24 |

Output of HDPE | KG/H | 90 | 140 |

Number of heating zone | ZONE | 4 | 4 |

Extruder heating power | KW | 21.4 | 21.4 |

Extruder driving power | KW | 22 | 37 |

Die-head |

Number of heating zone | ZONE | 3 | 3 |

Power of die heating | KW | 5.7 | 5.7 |

Max die pin diameter | MM | 180 | 180 |

Center distance of double head | MM | 250 | 250 |

Center distance of four-head | MM | 95 | 95 |

Machine main part brand:

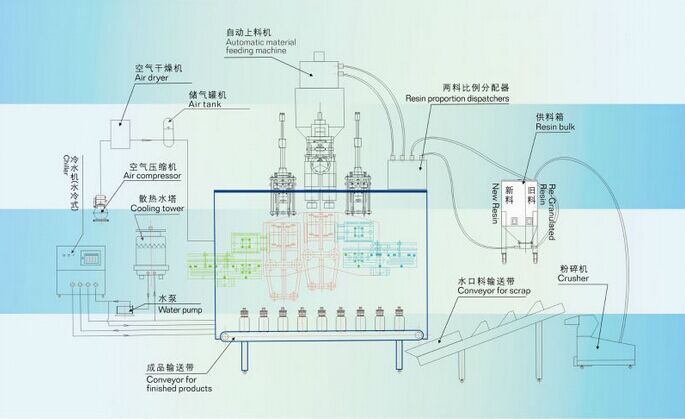

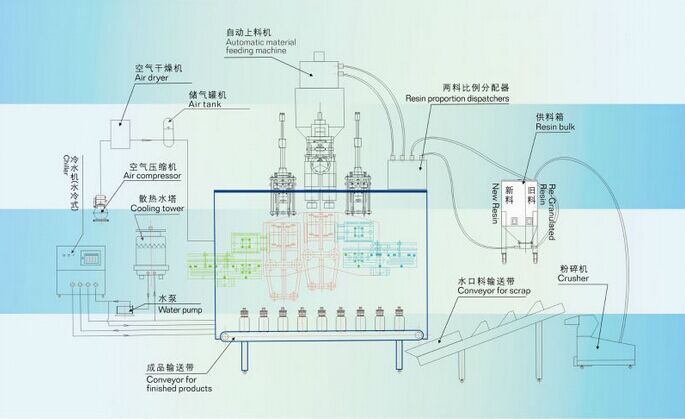

Machine layout drawing:

Our workshop:

Our certification:

Packaging & Shipping

The warranty period for Kinggle machine is one year with a life long maintenance. If the user

requires special quality guarantee, other stipulated warranty period may be made after mutual

agreement.

1. Reply the email and take action in 24 hours;

2. 100% Quality inspection before the shipment;

3. Can trainning clients operator for free in seller`s factory

4. Engineer overseas is avilable

5. Blowing mould and injection mould made orginal

6. Auxiliary machines for complate line.

7.Custimized design as requirements.

8.Introduce our engineer come to customer’s factory working!

Company Information

Sam Zhang

NINGBO KINGGLE MACHINERY CO.,LTD

TEL:0086 574 87103665

Mail:service@kinggle.cc

Skype:sam12130

Whatsapp/Viber:0086 15868155663