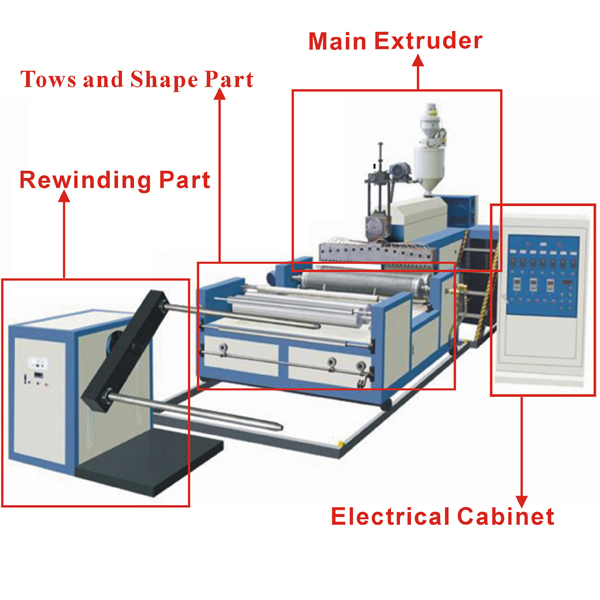

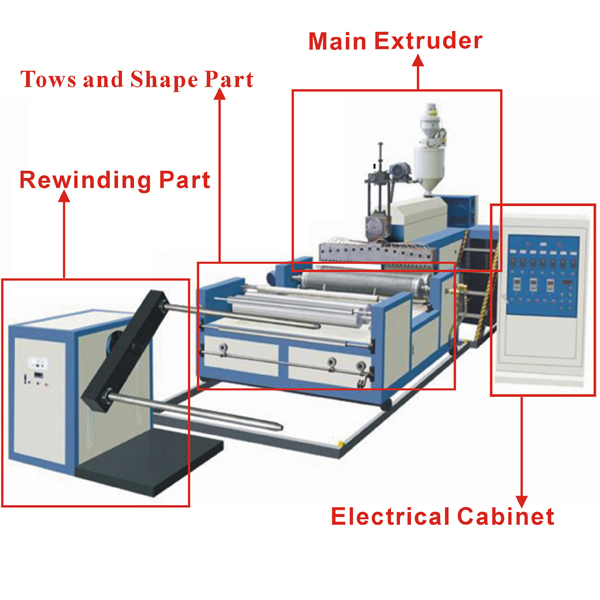

High Speed PE Bubble Film Making Machine

Feature

1.This air crew adopts the disposable shaping craft.

2.It is our factory that draws domestic and international advanced technology extensively, through a large number of production practices in having ordinary equipment originally, develop, design, can produced polyethylene compound bubble (cushion) membrane in succession. Designs science, practical.

3.Rational in structure of the machine.

Characteristic

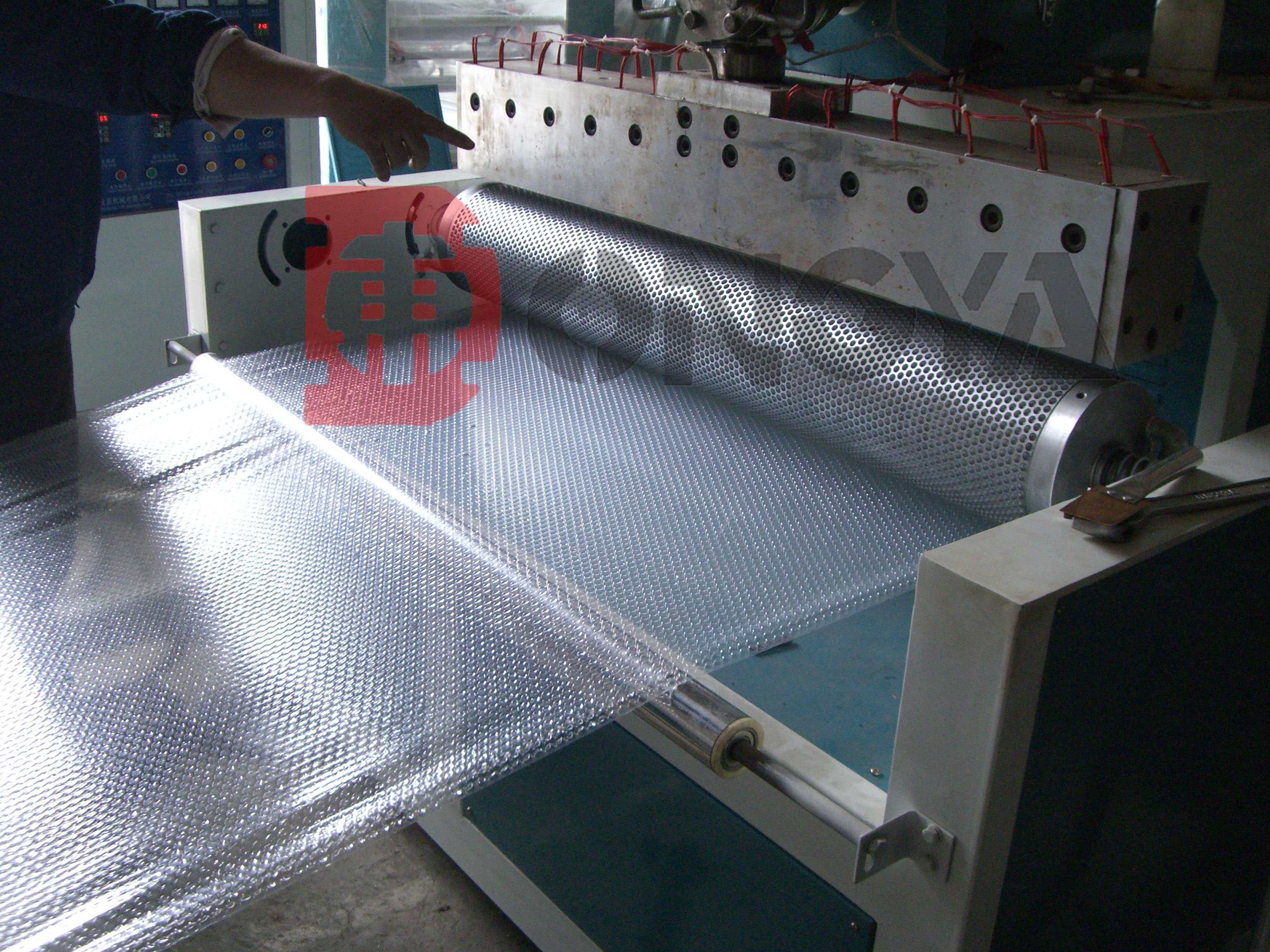

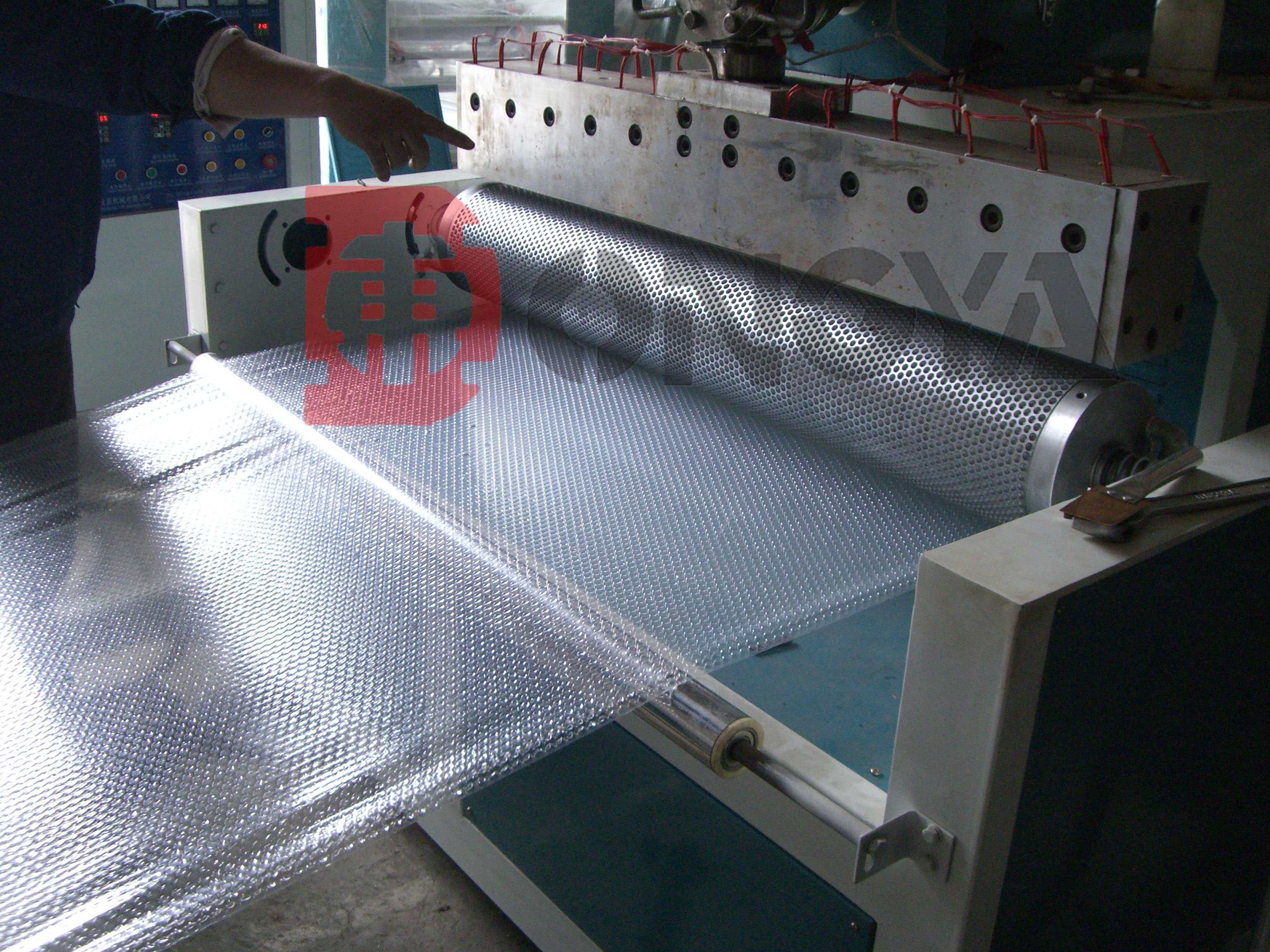

This machine adopts once- through shaping technique, thus has high efficiency and excellent product quality.

This machine set has such features as scientific and reasonable structure design, smooth and reliable running and convenient operation and maintenance.

Polyethylene aircushion film (also called polyethylene bubble film), which is divided into two kind: ordinary polyethylene aircushion film and composite polyethylene aircushion film, is a kind of packing material which has been widely used at present. It not only has good cushioning effect, shock resistance and heatsealing performance, but also has such advantages as good corrosion resistance and transparency , etc. So it has been widely used for packing, household wares, post parcel, bicycle , polyurethane furniture, etc.

Main Technical Parameter

Model | DY-2000 |

Main and auxiliary extruder screw diameter | Φ95mm |

L/D ratio | 30:1 |

Main and auxiliary extruder electrical power | 37kw |

Width of production | 2000mm |

Main bubble specification(arbitrary eligibility) | 6*3.2mm 10*3.6mm 25*10mm 30*10mm |

Output | 120-190kg/h |

Total installed capacity | 80kw |

Overall dimension | 6000*3900*3150mm |

Gross weight | 6000kg |

Model | DYF-1800 |

Main and auxiliary extruder screw diameter | Φ85mm |

L/D ratio | 30:1 |

Main and auxiliary extruder electrical power | 30kw |

Width of production | 1800mm |

Main bubble specification(arbitrary eligibility) | 6*3.2mm/10*3.6mm/25*10mm/30*10mm |

Output | 100-160kg/h |

Total installed capacity | 80kw |

Overall dimension | 6000*3700*3150mm |

Gross weight | 5500kg |

Model | DYF-1600 |

Main and auxiliary extruder screw diameter | Φ75mm |

L/D ratio | 30:1 |

Main and auxiliary extruder electrical power | 22kw |

Width of production | 1600mm |

Main bubble specification(arbitrary eligibility) | 6*3.2mm/10*3.6mm/25*10mm/30*10mm |

Output | 80-130kg/h |

Total installed capacity | 75kw |

Overall dimension | 6000*3500*3150mm |

Gross weight | 4000kg |

Pictures show

Application

The bubble film is made of LDPE material. It can be used for various packaging purposes such as moisture proving,

dust proving, shock proving, and static prevention. It can also make into laminated films with aluminized film, foamed

PE sheet, and paper are the applications of sun shading, heat insulation, and packaging.

Our Team And Customers

Certification

Training Service

Our Service

Welcome to visit our factory,bring you sample to test machine on the spo

Manual provided in English and operation video provided.

Guarantee Service

We guarantee the machine in good quality for one year since the day we supply qualified debugging.

Debugging Service

We are in charge of install and debug the equipment for free,including arrange our technicians train you the operation in our company or client’s factory!

After Service

In order to ensure the equipment in normal operation,we would be in charge of the service of supply the maintenance and spare parts,which would be helpful to make the machine in best running situation.

Maintenance Service

We have a powerful technical service team,which can meet with any emergency maintenance;The warehouse have a large stock of all type spare parts,which can solve the clients’ emergency requirement of spare parts.

Whole Life Service

When the time guarantee service finish,we still willing supply the whole life service,the most reasonable price and complete spare parts to clients.

New products

Any requirement,please feel freely contact us,we would service you with heart and soul.