https://youtu.be/T8YgWu6UFd0?si=TyrKVWiGkP-jyyjV Click this link to enjoy a visual tour of out factory

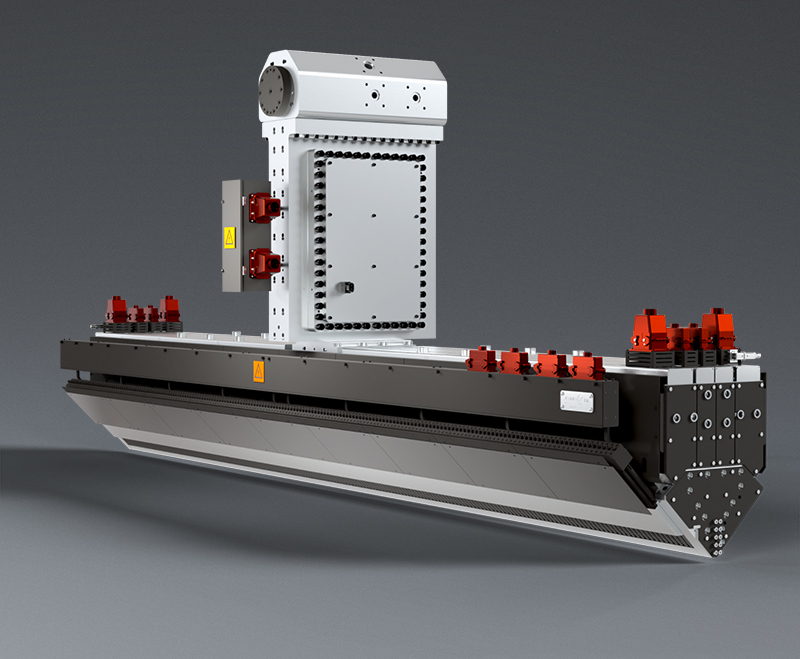

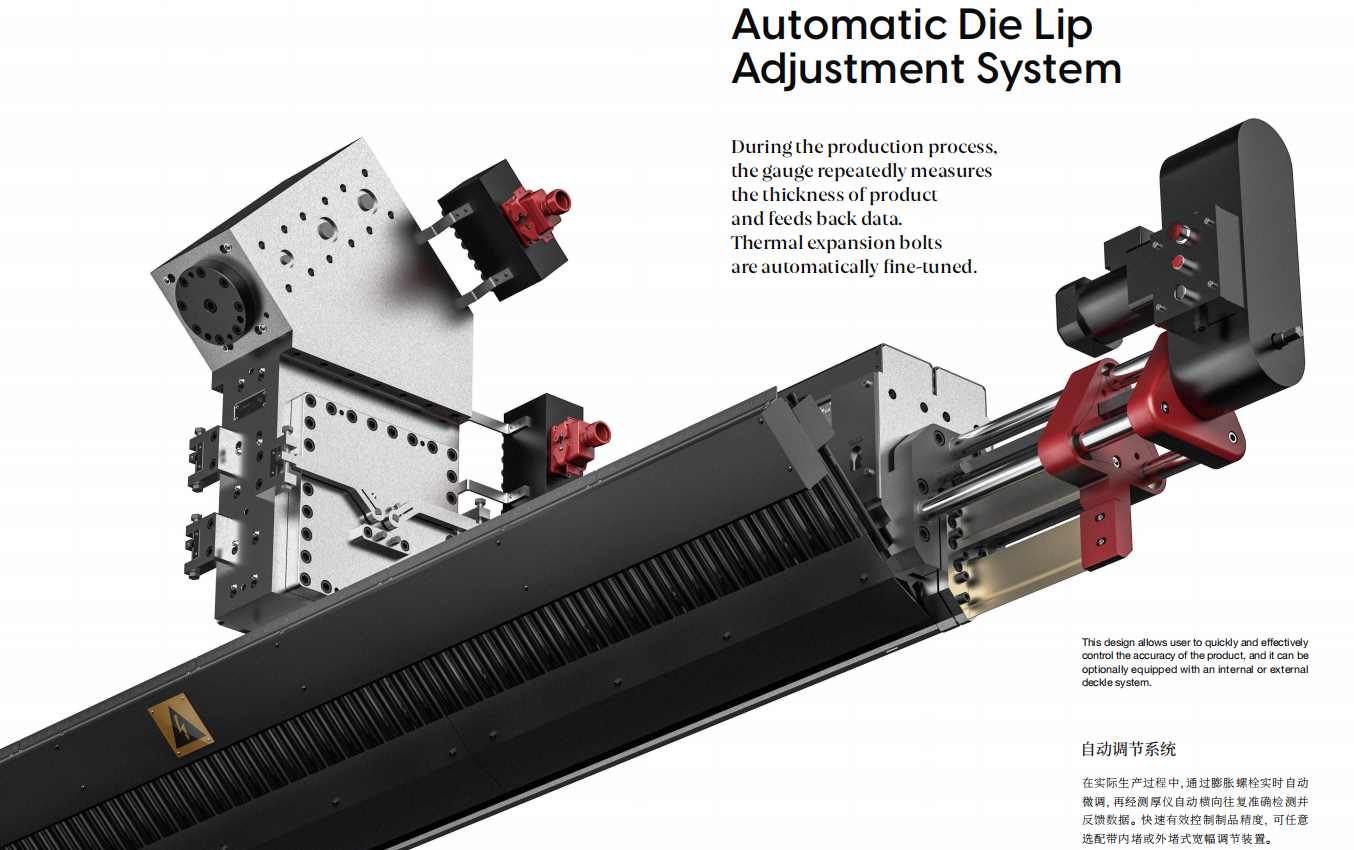

•Flexible choice for internal and external deckle system

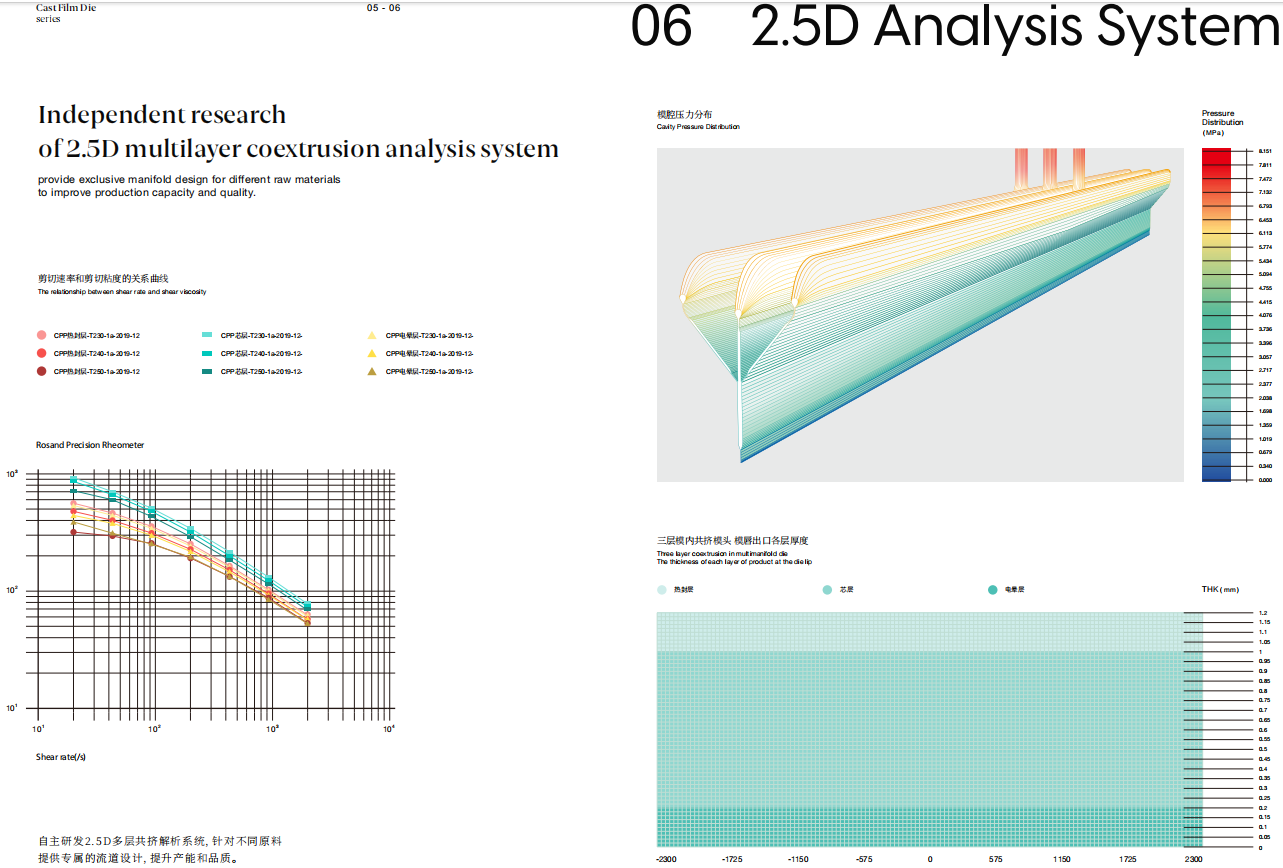

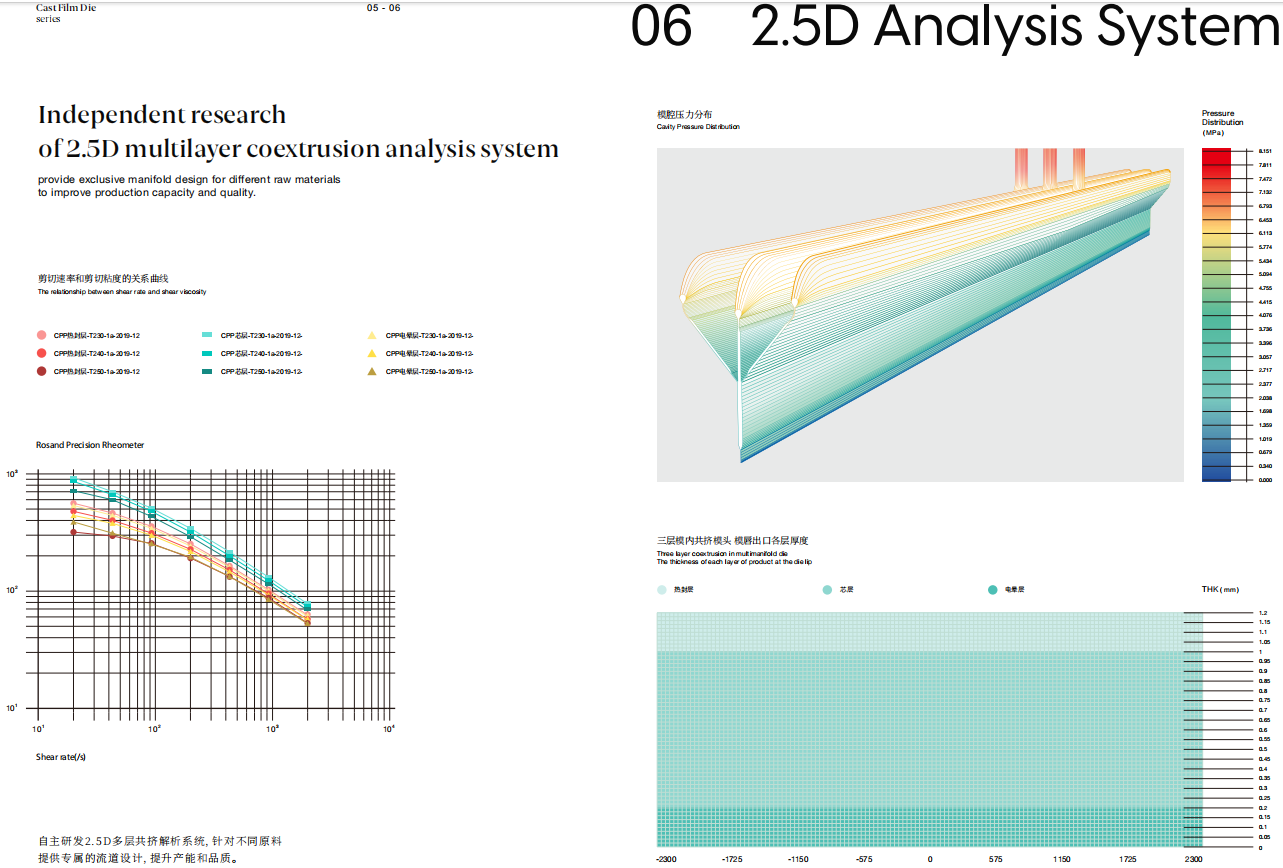

•The use of advanced polymer melt analyzer combined with “state of

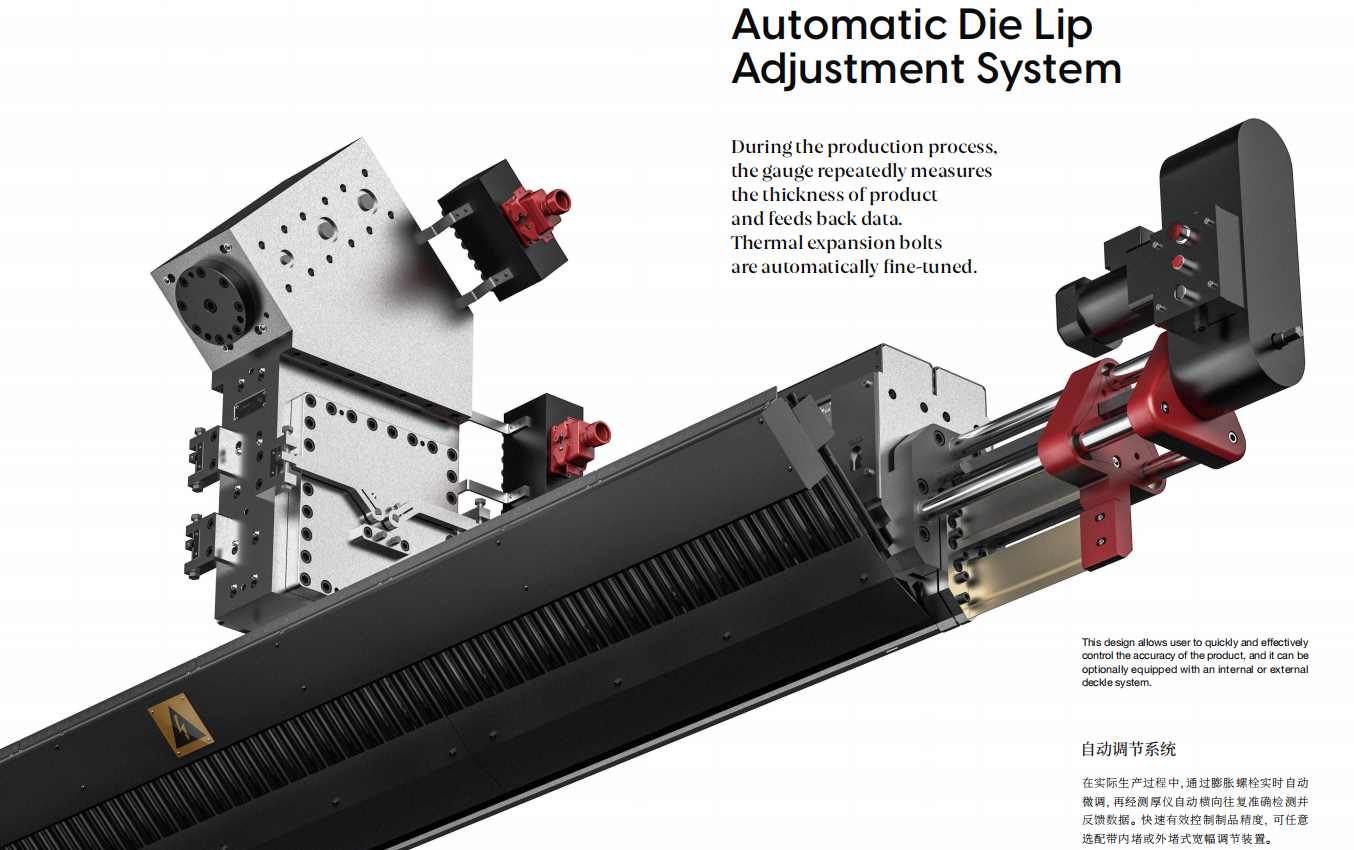

the art” Die Flow Software assures optimum design and performanc of the die. Die fine adjustment systems are available as manual, or automatic, push only, or push and pull.

•For the automatic control die, the expansion bolts are completely isolated from the die body heat for optimum performance and response time.

•When equipped with a suitable gauging system, product thickness

can be controlled to ±1%.

•Both internal and external deckling systems are available.

Technical Parameters:

Die width: tailor made up to 8000mm

Product thickness tolerance: ±3%

Die lip radius: R0.01mm or less

Die lip surface finish: up to Ra 0.01μm

Flow channel surface harden treatment by

chromium plating. Plating thickness: 0.02-0.03mm

Hardness: HV900-1000

Roughness of flow channel: Ra 0.01-0.02

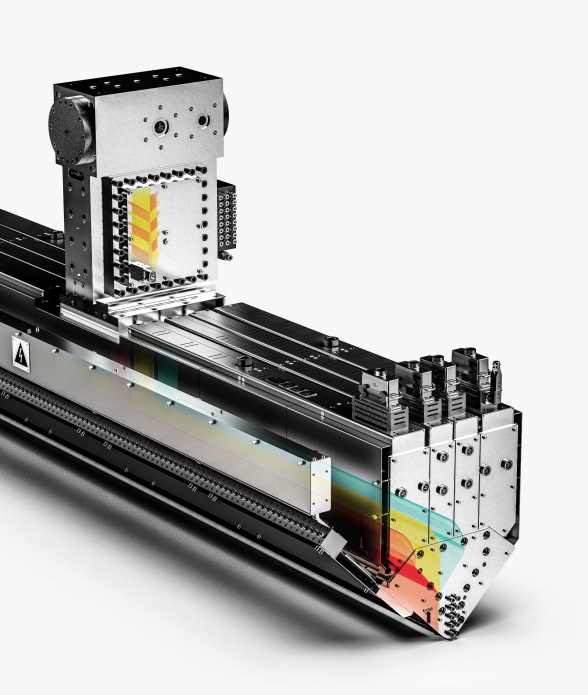

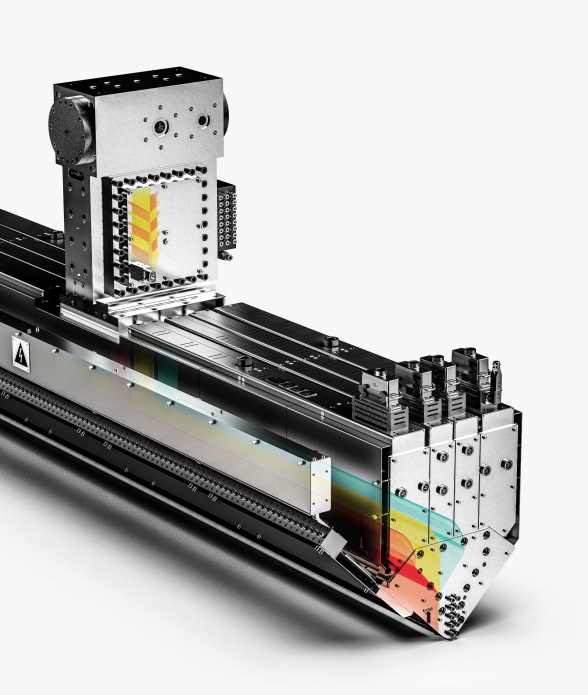

•Multi-manifold dies are used for very thin skin layers compared to the total thickness and

structures with very large viscosity and temperature differences in adjacent layers.

The uniformity of the co-extruded layer is within 10%

The temperature difference of each layer can be up to 20°C