Sheet, Heavy Gauge Sheet,Foam Sheet Dies

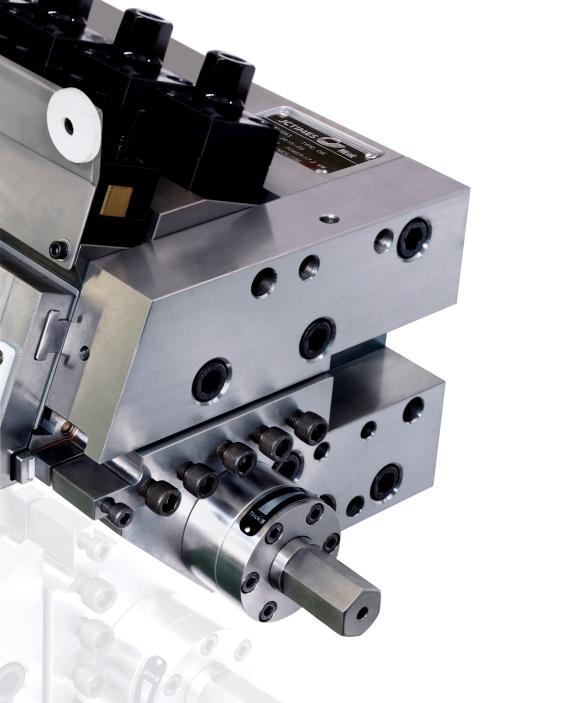

Multiple lip gap adjustment systems with push only, push and pull and differential adjustment structure.

The fast lip open system can adjust the lip gap on line. The quick and efficient adjustment system is easy to operate and save raw materials.

Various types of restrictor bar systems are suitable for different applications, allowing one die to be used for multiple raw material and output requirements.

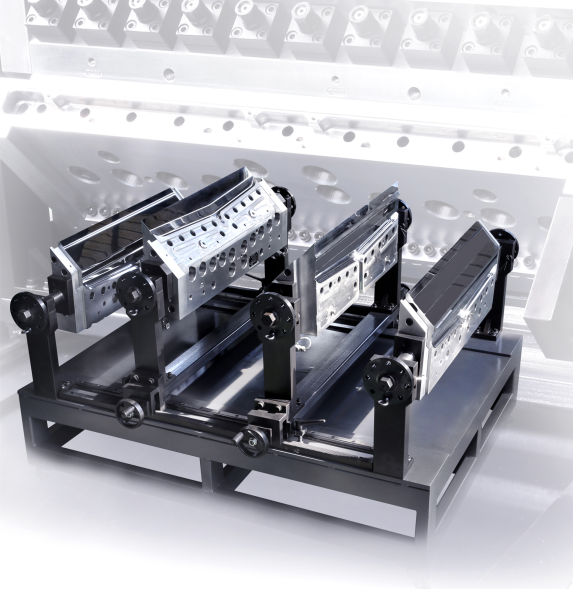

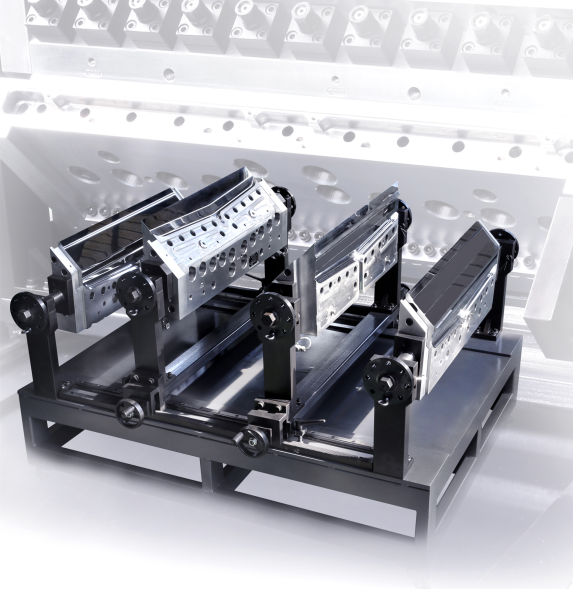

The various kinds of width adjustment systems allow the production of many different widths.

Precise flow channel design and die lip temperature control ensures high quality foam sheet production

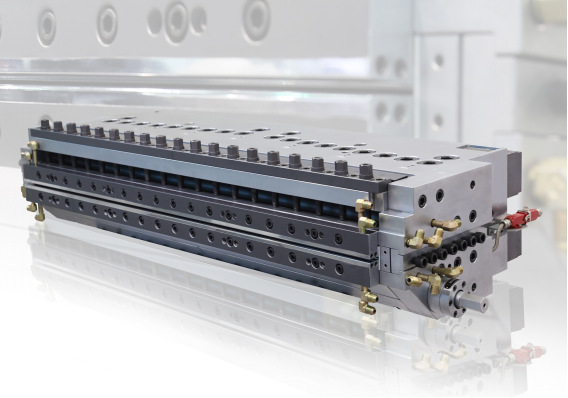

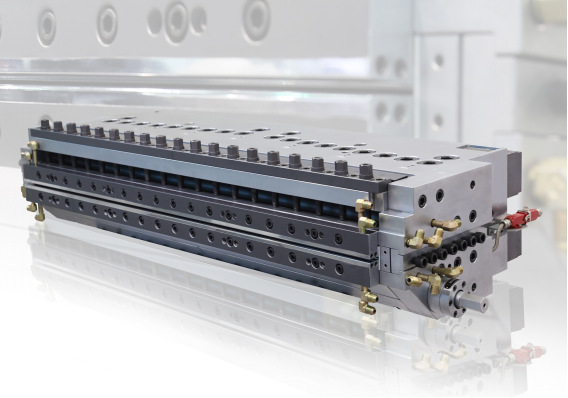

PVC Foam Sheet Dies.

Application: Foam PVC building products, bathroom fixtures, poster boards etc.

Die structure: Special design for flow channel and multiple oil temperature control

zones at dip lips which stabilize the flow and calibrating area.

Updated design for PVC celuka dies: The lip exit is equipped with a unique water

cooling system, to reduce foam density and make the surface harder.

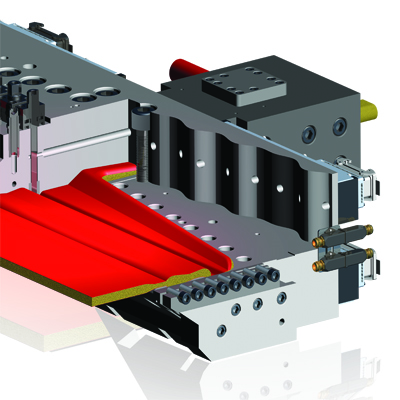

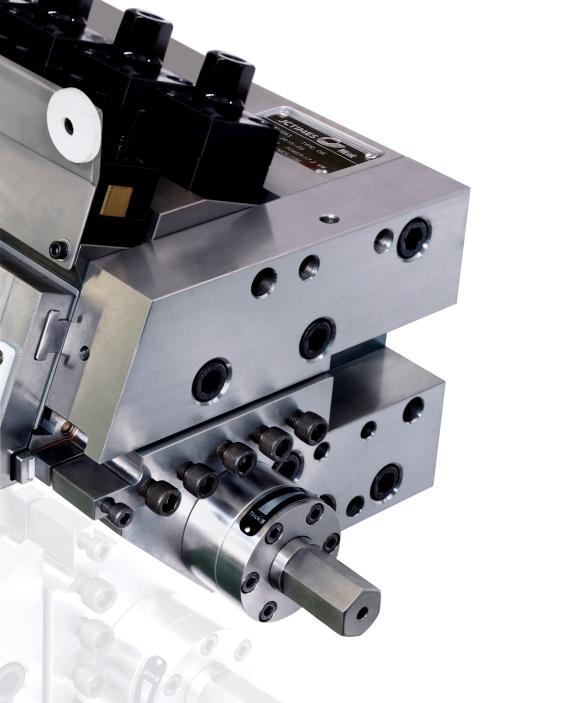

Fast Lip Open Dies

Adjust the lip gap on line.

Manual or automatic deckle systems are available

Upper lip fine adjustment system can be push only ,or push and pull

Restrictor bar as an option

Fast lip open range: ±2mm

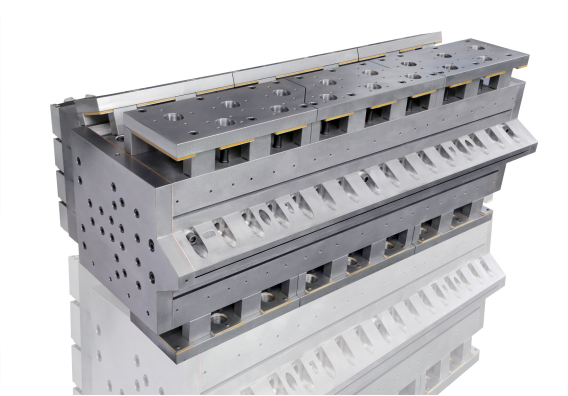

Common Sheet Dies

Upper lip fine adjustment system

Lower lip fixed, or adjustable

Restrictor bar for option

Various width adjust systems are optional

PC Optical Grade Automatic Control Sheet Dies

Push only or push and pull automatic control system

Adjustment bolts on 25.4mm or 30mm centers Close to nip rolls die contour design

Close to nip rolls width adjustment system as option

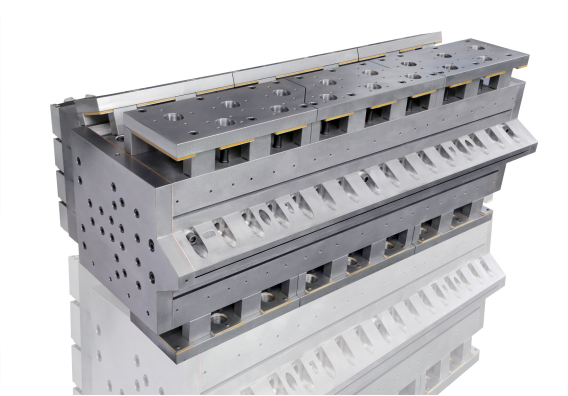

Heavy Gauge Sheet Dies

With 90°restrictor bar

Upper die lip adjustment range max.: 11mm

Width adjustment system optional

Product thickness max.: 60mm